Method for efficiently removing total nitrogen from printing and dyeing wastewater by combining multiple methods

A technology for printing and dyeing wastewater and printing wastewater, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

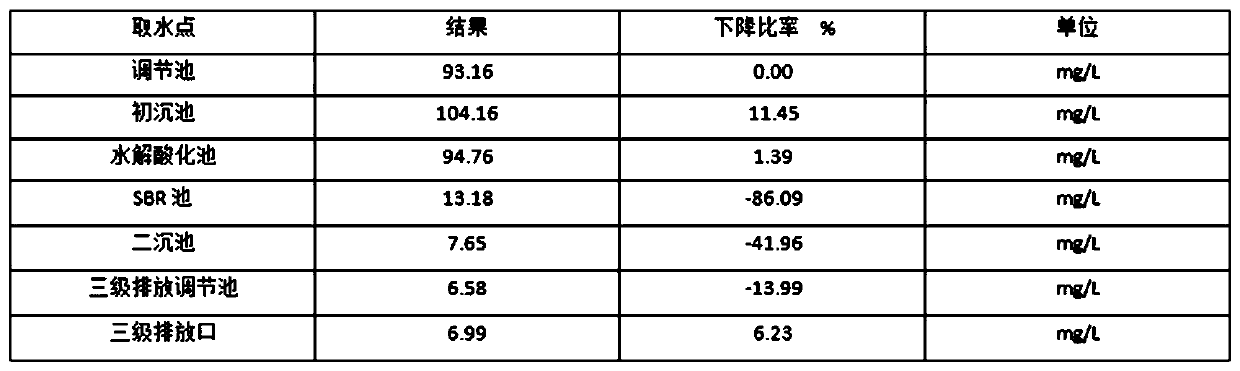

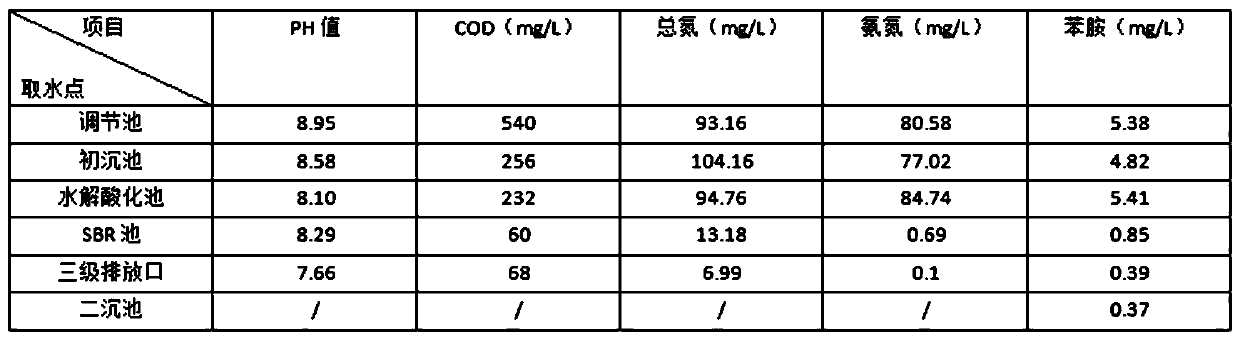

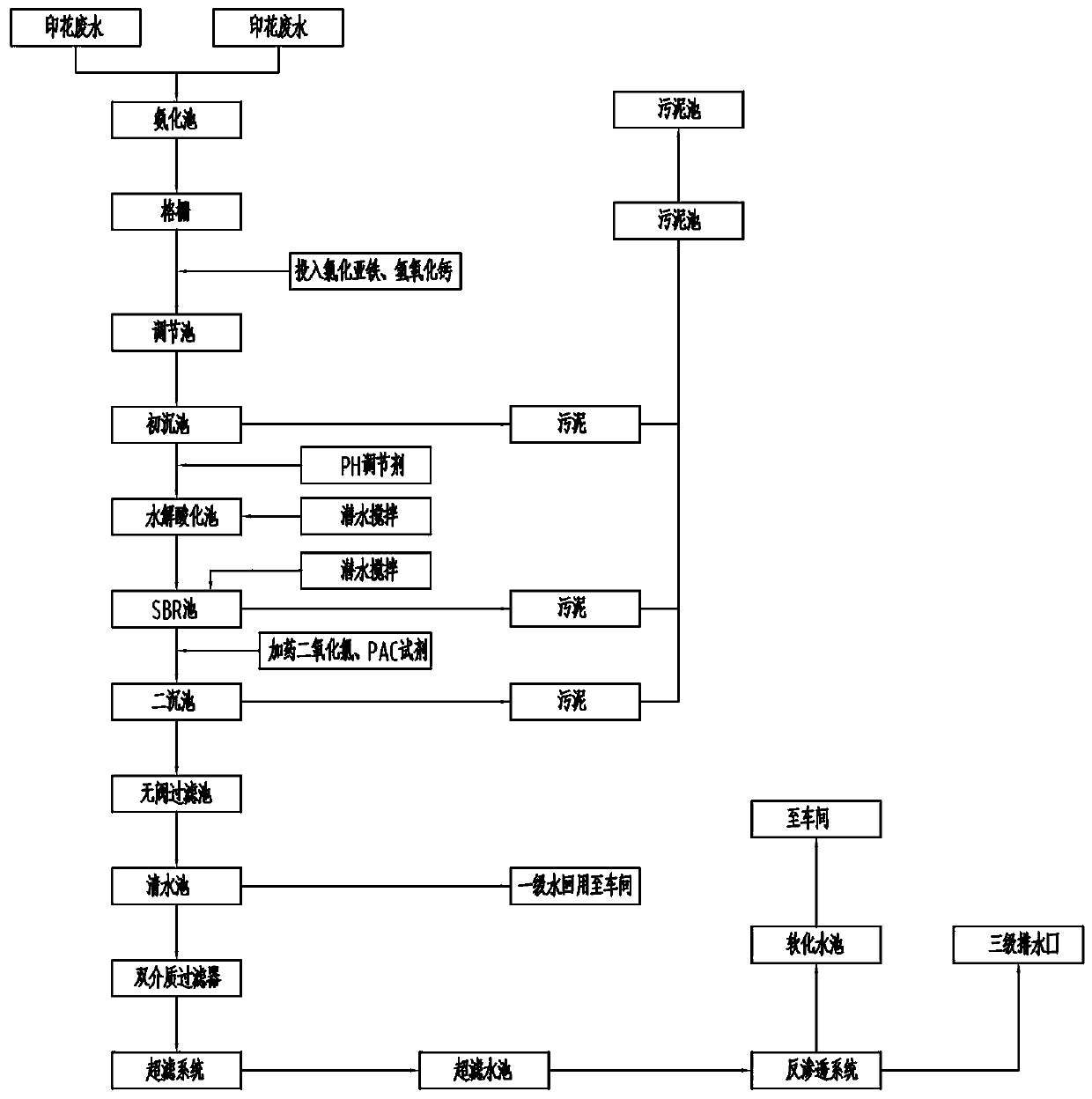

[0031] The first step, S1 ammonification, first introduces printing wastewater (total nitrogen about 600mg / L, ammonia nitrogen about 15 mg / L) into the ammoniation tank filled with activated sludge, and pours it into the printing wastewater in the ammoniation tank Add mercerizing lye to adjust the pH value of the printing wastewater to between 9 and 11; the higher the pH value, the better the ammoniation effect. During this period, the printing wastewater is kept in the ammoniation tank for 14 to 18 hours to ensure that the microorganisms in the activated sludge in the ammoniation tank fully decompose the organic nitrogen in the printing and dyeing wastewater into ammoniacal nitrogen. In this step, the ammonia nitrogen conversion rate of the printing wastewater after ammoniation treatment can reach 60% ± 5% to about (total nitrogen content about 600mg / L, ammonia nitrogen about 360mg / L), at this time, the ammonia nitrogen at the bottom of the ammonification pool Activated sludge...

Embodiment 2

[0046] The difference between this example and Example 1 is that the removal in the above step S2 can also be replaced by chemical sedimentation. The detailed steps are: after the printing wastewater is treated in step S1, ammonia nitrogen is converted into struvite: using magnesium salt and phosphate, according to the following formula:

[0047] Mg2+ + PO43- + NH4+ + 6H2O= MgNH4PO4.6H2O (1); Mg2+ + HPO42 - + NH4+ +6H2O=MgNH4PO4 .6H2O + H+ (2); Mg2+ + H2PO4- + NH4+ + 6H2O=MgNH4PO4 .6H2O + 2H+ (3 );

[0048] After the printing wastewater is blown off, the total nitrogen can be reduced by 60%±3% to about 240mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com