Processing device of valve seat plane and processing method

A technology for processing equipment and valve seats, which is applied in the field of four-way reversing valve processing and manufacturing, can solve problems that affect the service life of four-way reversing valves, poor sealing of valve seats and main slide valves, uneven force on tools, etc., and achieve improved Broaching pass rate, safety improvement, and the effect of improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing.

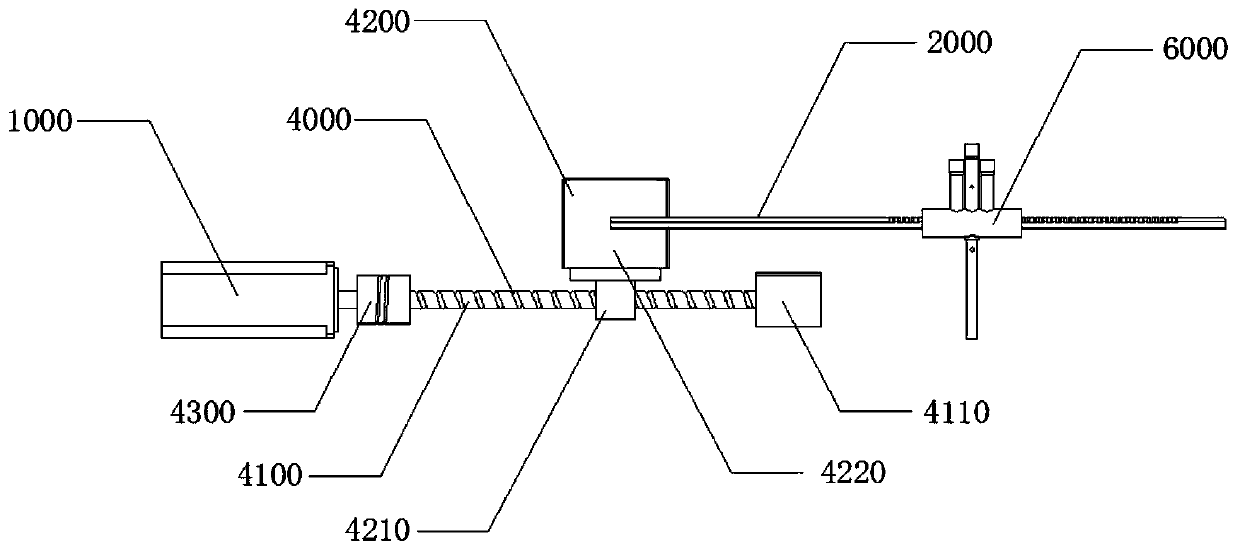

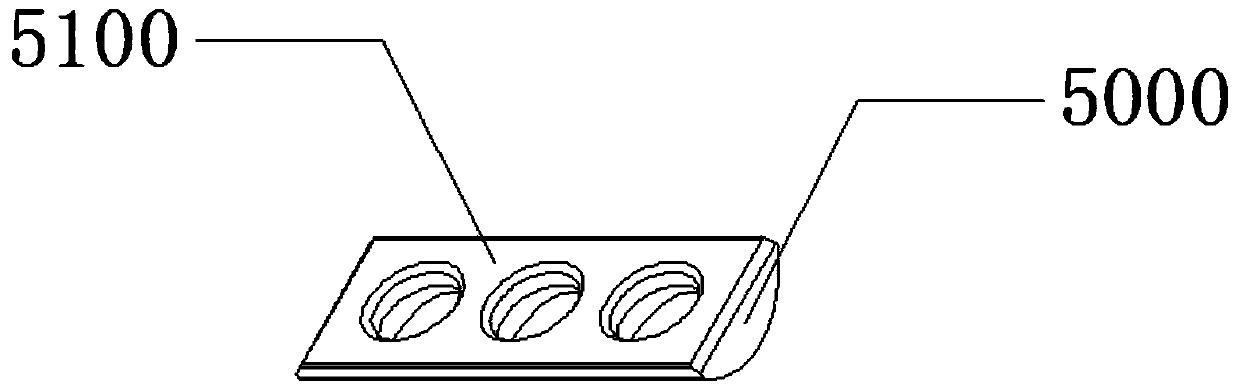

[0055] Such as figure 1 and Figure 5 As shown, this embodiment provides a valve seat plane processing equipment, the valve seat plane processing equipment includes a servo motor 1000, a tool 2000 and a closed-loop control mechanism 3000; the servo motor 1000 is connected to the tool 2000 through a connection assembly 4000 to drive The cutter 2000 processes the valve seat 5000; the closed-loop control mechanism 3000 communicates with the servo motor 1000, and the closed-loop control mechanism 3000 close-loop controls the target output of the servo motor 1000 according to the load information of the cutter 2000.

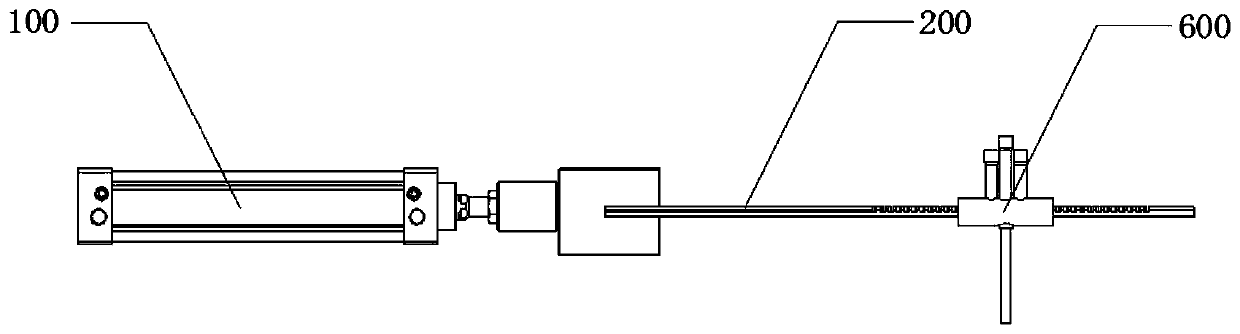

[0056] Such as figure 2 and Figure 6 As shown, the existing valve seat plane processing equipment includes an oil cylinder 100, a cutter 200 and an open-loop control mechanism. The oil cylinder is connected with the tool 200 through a connecting fixture to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com