Positive electrode material and preparation method thereof, and lithium ion battery containing positive electrode material

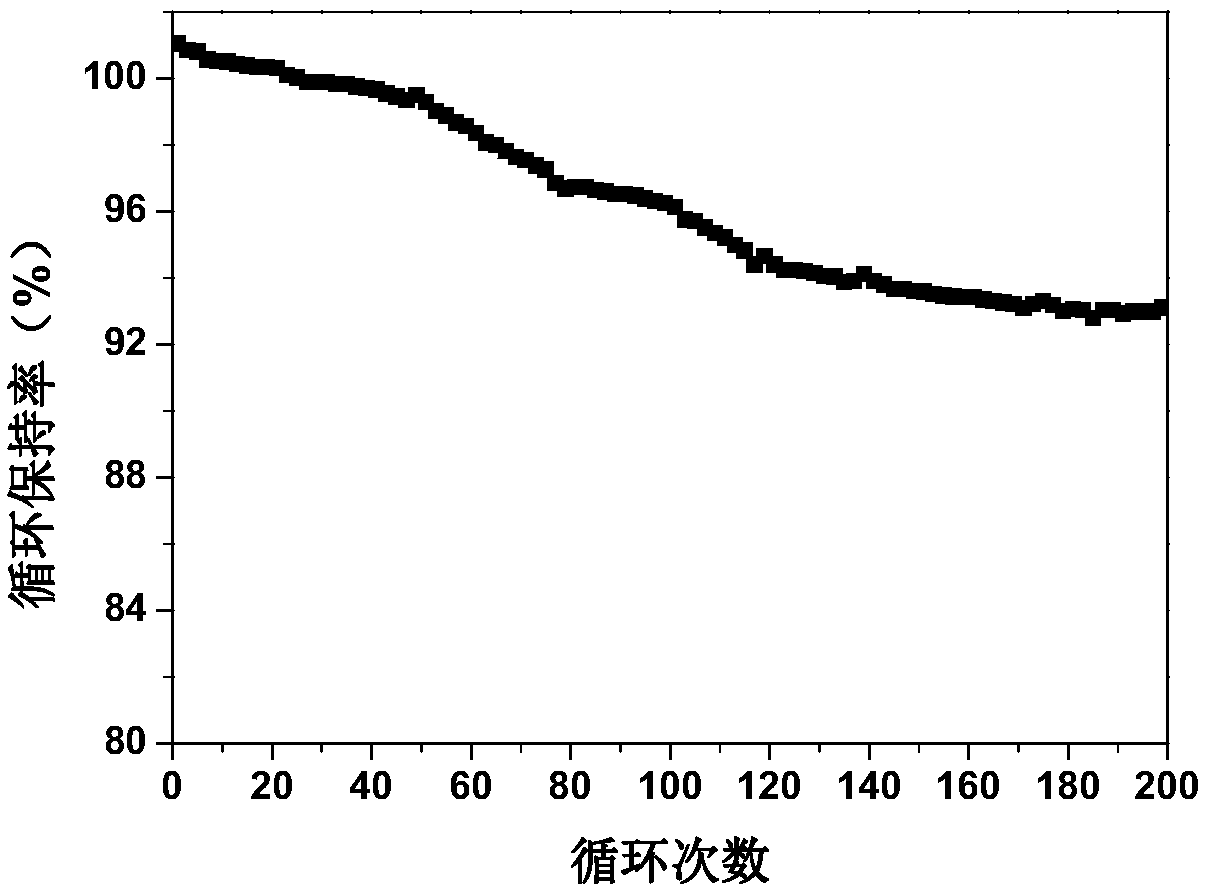

A technology for lithium-ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low cycle performance, reduce the amount of residual alkali, improve high-temperature storage performance and safety performance, and stabilize the surface of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The preparation process of the positive electrode material in this embodiment is as follows:

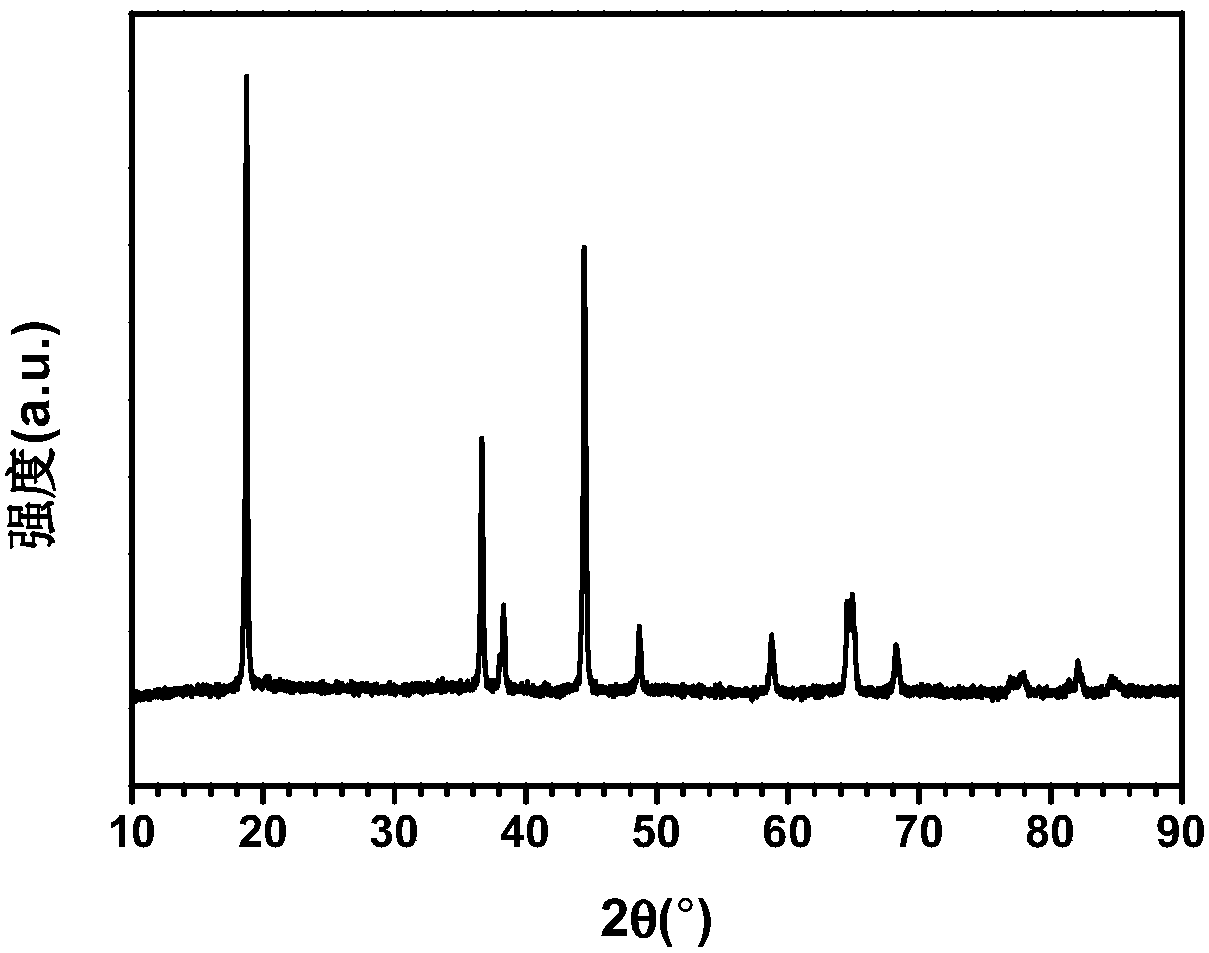

[0066] (1) Weigh the precursor (Ni 0.70 co 0.15 mn 0.15 )(OH) 2 100.00g, placed in an oxygen atmosphere furnace and sintered at 750°C for 4h to obtain primary sintered powder; weigh 65.28g lithium hydroxide monohydrate (LiOH·H 2 O) mixed with primary sintering powder (primary sintering powder and lithium source molar ratio 1:1) and then sintered at 880°C for 12h, the heating rate was 5°C / min, and the atmosphere was empty. After cooling with the furnace, grind and sieve to obtain secondary sintered powder.

[0067] (2) Weigh iridium oxide (IrO 2 ) 4.760g and the secondary sintered powder obtained in step (1) were ultrasonically dispersed in 650mL of deionized water, then transferred to a 1L hydrothermal reaction kettle, and reacted at 180°C for 12h. After filtration, vacuum-dry at 120°C for 12 hours to obtain hydrothermal product powder.

[0068] (3) Sinter the hydrothe...

Embodiment 2

[0083] The preparation process of the positive electrode material in this embodiment is as follows:

[0084] (1) Weigh the precursor (Ni 0.80 co 0.10 mn 0.10 )(OH) 2 100.00g, placed in an oxygen atmosphere furnace and sintered at 650°C for 12h to obtain primary sintered powder; weigh 57.47g lithium carbonate (Li 2 CO 3 ) and primary sintering powder (the molar ratio of primary sintering powder to lithium source is 1:1) and then sintered at 840°C for 18 hours, the heating rate is 10°C / min, the atmosphere is oxygen atmosphere, and the oxygen concentration is >95%. After cooling with the furnace, grind and sieve to obtain secondary sintered powder.

[0085] (2) Weigh iridium tetrafluoride (IrF 4 ) 0.714g and the secondary sintered powder obtained in the step were ultrasonically dispersed in 550mL of deionized water, then transferred to a 1L hydrothermal reaction kettle, and reacted at 160°C for 16h. After filtration, vacuum-dry at 100°C for 12 hours to obtain hydrothermal...

Embodiment 3

[0092] The preparation process of the positive electrode material in this embodiment is as follows:

[0093] (1) Weigh the precursor (Ni 0.80 co 0.15 Al 0.05 )CO 3 100.00g, placed in an oxygen atmosphere furnace and sintered at 800°C for 20h to obtain a primary sintered powder; weigh 57.47g of lithium hydroxide monohydrate (LiOH·H 2 O) mixed with primary sintering powder (primary sintering powder and lithium source molar ratio 1:1) and then sintered at 780°C for 20h, the heating rate was 5°C / min, the atmosphere was an oxygen atmosphere, and the oxygen concentration was >98%. After cooling with the furnace, grind and sieve to obtain secondary sintered powder.

[0094] (2) Weigh iridium nitrate (Ir(NO 3 ) 4 ) and iridium acetate (the total mass of the mixture is 2.337g) and the secondary sintered powder obtained in step (1) was ultrasonically dispersed in 750mL deionized water, and then transferred to a 1L hydrothermal reactor, and reacted at 250°C for 16h. After filtrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com