Clean high-temperature co-firing furnace for household waste disposal

A domestic garbage and cleaning technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of incomplete treatment of toxic and harmful substances, insufficient combustion, etc., and achieve the effects of stable operation, improved efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail in combination with specific embodiments and with reference to the accompanying drawings.

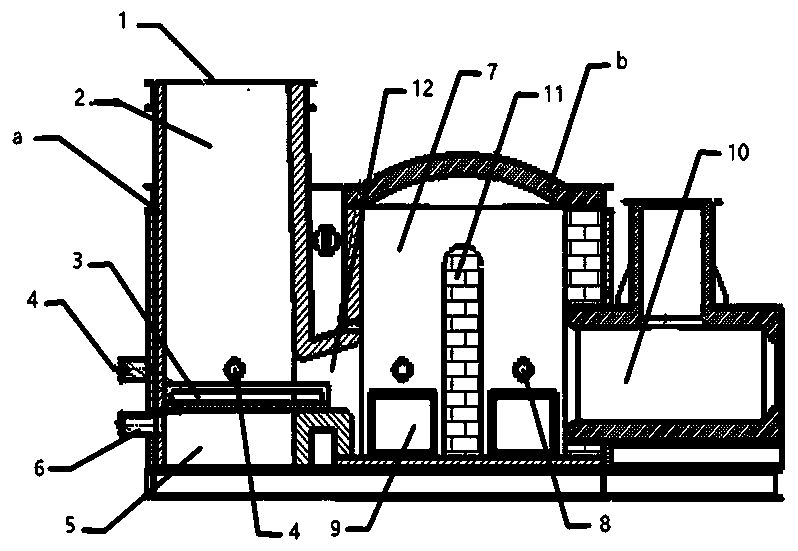

[0026] Concrete structure of the present invention, refer to figure 1 As shown, it includes the garbage first combustion chamber a and the flue gas second combustion chamber b; the garbage first combustion chamber a from top to bottom is the feed inlet 1, the first combustion chamber furnace 2, the fire grate 3, the primary air inlet 4, the slag collection Pit 5, slag removal port 6; second combustion chamber furnace 7, secondary air inlet 8, ash removal port 9, smoke exhaust port 10, partition wall 11 arranged in the second combustion chamber; garbage primary combustion chamber a and flue gas secondary combustion chamber b are connected by flue gas passage 12.

[0027] Garbage materials are put into a combustion chamber furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com