Split type thermostatic valve

A thermostatic valve and split-type technology, applied in the field of thermostatic sanitary ware, can solve the problems that the thermostatic valve structure is difficult to meet the needs of manufacturing, affect product forming and subsequent processing, reduce the stability of the valve body forming process, etc. Production difficulty, simple and convenient installation process, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

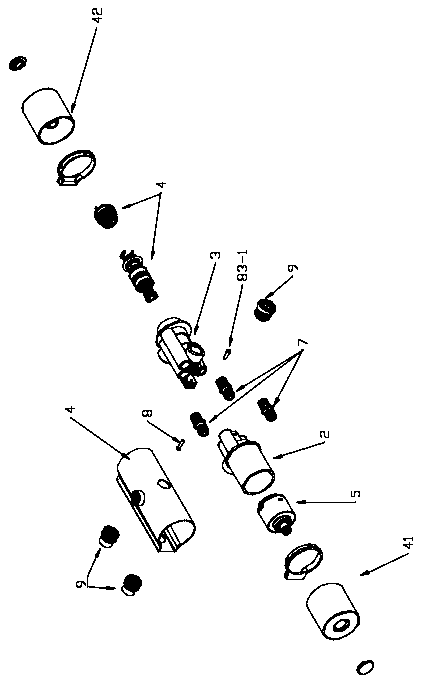

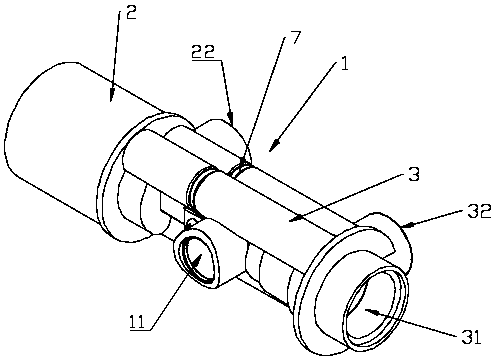

[0048] Such as Figure 1-6 As shown, a split-type thermostatic valve includes a main valve body 1, a casing 4, a switch spool 5, and a thermostatic spool 6. The casing 4 is a hollow cylindrical structure in the middle, and also includes a switch spool handwheel 41, a thermostatic The spool hand wheel 42 is connected with the handles of the switch spool 5 and the thermostatic spool 6 respectively, and the rotating hand wheel drives the handle to rotate. The shell 4 is also provided with an opening for the pipe joint 9 to pass through.

[0049] Such as Figure 1-5 As shown, the main valve body 1 is a split structure, including the left valve body 2, the right valve body 3 and the plug-in parts 7 for connecting the left and right valve bodies. The main valve body 1 is also provided with at least one set for connecting Fasten the fastening parts 8 of the left valve body 2 and the right valve body 3.

[0050] This embodiment adopts a split structure, shortens the process length ...

Embodiment 2

[0071] Compared with the first embodiment, this implementation mainly provides another fastening method for the left and right valve bodies.

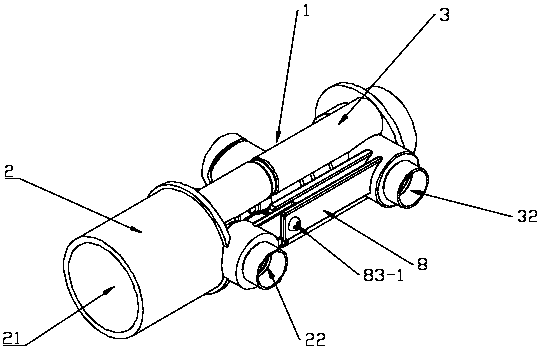

[0072] Such as Figure 7-15 As shown, the main valve body 1 is a split structure, including the left valve body 2, the right valve body 3 and the plug-in parts 7 for connecting the left and right valve bodies. The main valve body 1 is also provided with at least one set for connecting Fasten the fastening parts 8 of the left valve body 2 and the right valve body 3. In this embodiment, the plug-in part 7 is integrally formed with the water flow channel 12 of the right valve body 3, the water flow channel of the left valve body 2 is open and provided with a socket 13, and the plug-in part 7 of the right valve body 3 is inserted into the left valve In the socket 13 of the body 2, the assembly of the left and right valve bodies is realized. In this embodiment, a set of fastening parts 8 is provided on each docked water flow channel. In th...

Embodiment 3

[0093] Compared with Example 2, such as Figure 16 As shown, the difference in this embodiment is that the thermal sensor 64 is a memory alloy spring 64B. Memory alloy springs are gradually being applied because of their excellent thermal sensitivity. combine Figure 10 , 12 , 13, the current limiting assembly 66 in this embodiment is a single sliding sleeve 66B, and the two ends of the single sliding sleeve 66B respectively form a water inlet gap for heating and cold water circulation with the limiting step 35 of the current limiting assembly and the end of the valve head 63 , the middle part of the single sliding sleeve 66B is provided with a water-passing ring step, the return spring 65 and the memory alloy spring 64B are arranged on the left and right sides of it, and pushing the single sliding sleeve 66B affects its side end and the limiting step 35 of the current limiting component, the valve The size of the gap at the end of the head 63 then affects the actual water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com