Continuous jet descaling system for cold-state metal part surface

A technology for descaling system and metal parts, applied in the direction of workpiece surface treatment equipment, metal rolling, metal rolling, etc., can solve the problems of cold rolling production line pollution, unable to meet the requirements of cold rolling, etc., to reduce land occupation, Reduce the process length and deal with the effect of short process section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

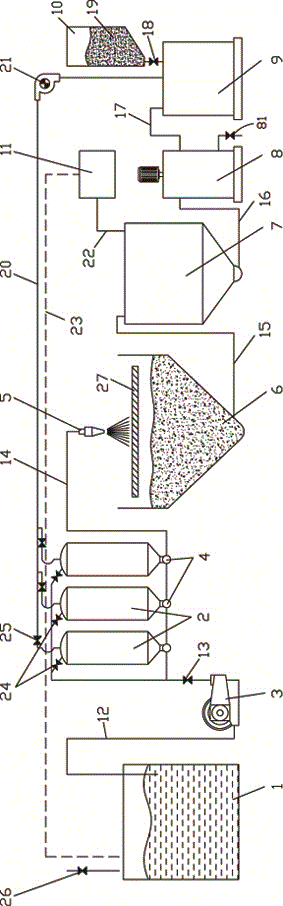

[0021] see figure 1 , The cold metal surface jet continuous descaling system of the present invention includes a water tank 1; a pre-pressed sand tank 2, which is connected to the water tank 1 through a pipeline 12, a control valve 13, 24 and a pressurizing device 3; A sand-water mixer 4 is arranged at the outlet of the sand tank 2; a set of spray system 5 for descaling, the inlet of which is connected to the sand-water mixer 4 through a pipeline 14; a set of collection pools 6 for collecting various mixtures after descaling, set Below the injection system 5; the sedimentation tank 7 is connected to the bottom of the collection tank 6 through the pipeline 15; the filter screener 8 is connected to the bottom of the sedimentation tank 7 through the pipeline 16, and the bottom of the filter screener 8 is provided with a discharge port and a corresponding control valve 81; The sand mixing tank 9 is connected to the upper part of the filter and screener 8 through a pipeline 17, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com