Method for deoxidizing copper or copper alloy, method for preparing high-purity copper or copper alloy, and high-purity copper or copper alloy obtained by the method

A technology for copper alloy and high-purity copper, which is applied in the field of copper and copper alloy preparation, can solve the problems of high oxygen content of copper and copper alloy and cannot meet the requirements of oxygen content of pure copper and copper alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

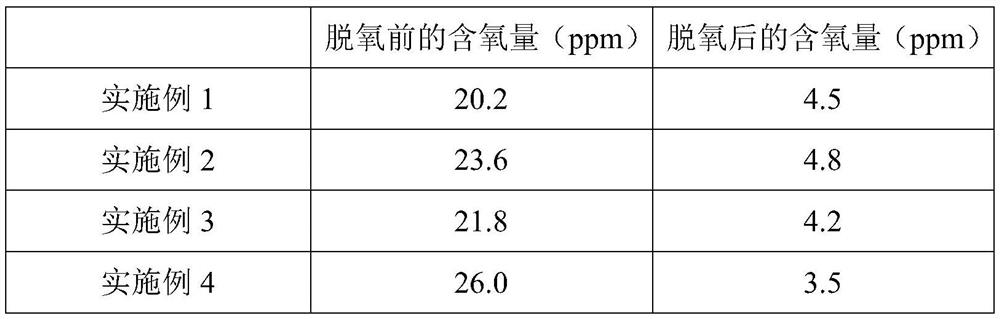

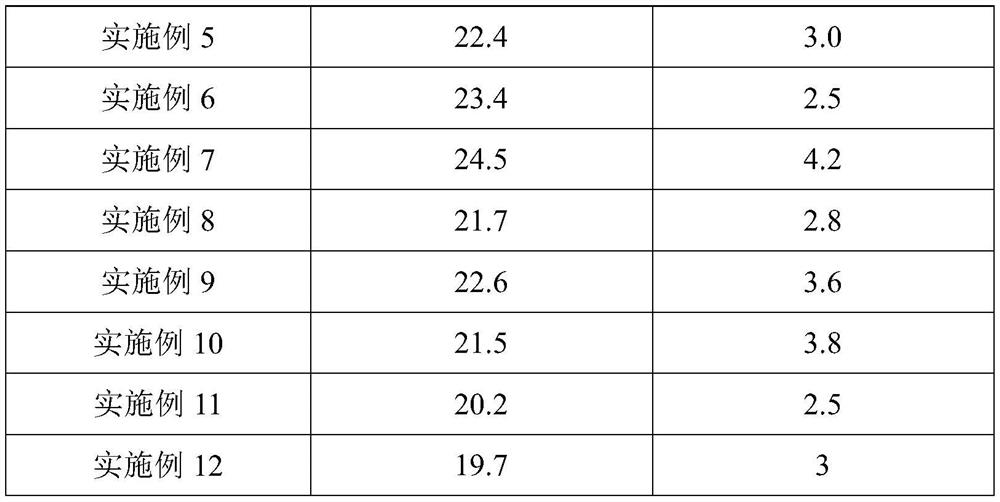

Examples

Embodiment 1

[0047] The copper deoxidation method of the present embodiment may further comprise the steps:

[0048] (1) Pretreatment of copper metal material and covering agent

[0049] The covering agent is composed of the following components in mass percentage: Na 2 B 4 o 7 65%, SiO 2 20%, NaF 10%, Na 3 AlF 6 5%. First, according to the above ratio, the Na 2 B 4 o 7 , NaF, Na 3 AlF 6 and SiO 2 Put them into a mixing tank after weighing them respectively, then ball mill them on a ball mill for 3 hours, then put them into a drying box, and dry them at 150°C for 8 hours to remove moisture. The copper metal material is preheated at 450°C to remove moisture.

[0050] (2) Melting of metal material and covering agent

[0051] Argon gas is introduced from the bottom of the intermediate frequency induction furnace, and the gas flow rate is 0.5m 3 / h, the time is 10min, then preheat the furnace to 650°C; then add the pretreated copper metal material, and then add a covering age...

Embodiment 2

[0057] The copper deoxidation method of the present embodiment may further comprise the steps:

[0058] (1) Pretreatment of copper metal material and covering agent

[0059] The covering agent is composed of the following components in mass percentage: Na 2 B 4 o 7 60%, SiO 2 20%, NaF 10%, Na 3 AlF 6 10%. First, according to the above ratio, the Na 2 B 4 o 7 , NaF, Na 3 AlF 6 and SiO 2 Put them into a mixing tank after weighing them respectively, then ball mill them on a ball mill for 4 hours, then put them into a drying oven, and dry them at 250°C for 9 hours to remove moisture. The copper metal material is preheated at 430°C to remove moisture.

[0060] (2) Melting of metal material and covering agent

[0061] Inert gas such as helium is introduced from the bottom of the intermediate frequency induction furnace, and the gas flow rate is 0.8m 3 / h, the time is 8min, then preheat the furnace to 600 °C; then add the pretreated copper metal material, and then a...

Embodiment 3

[0067] The copper deoxidation method of the present embodiment may further comprise the steps:

[0068] (1) Pretreatment of copper metal material and covering agent

[0069] The covering agent is composed of the following components in mass percentage: Na 2 B 4 o 7 70%, SiO 2 15%, NaF 10%, Na 3 AlF 6 5%. First, according to the above ratio, the Na 2 B 4 o 7 , NaF, Na 3 AlF 6 and SiO 2 Put them into a mixing tank after weighing them respectively, then ball mill them on a ball mill for 6 hours, then put them into a drying oven, and dry them at 200°C for 10 hours to remove moisture. The copper metal material is preheated at 400°C to remove moisture.

[0070] (2) Melting of metal material and covering agent

[0071] Argon gas is introduced from the bottom of the intermediate frequency induction furnace, and the gas flow rate is 0.6m 3 / h, the time is 6min, then preheat the furnace to 680 ° C; then add the pretreated copper metal material, and then add a covering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com