A method and device for preparing high-yield coke by combined roasting and carbonization

A yield and baking technology, applied in coke ovens, products, reagents, etc., can solve the problem of low coke yield and achieve the effect of increasing coke yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

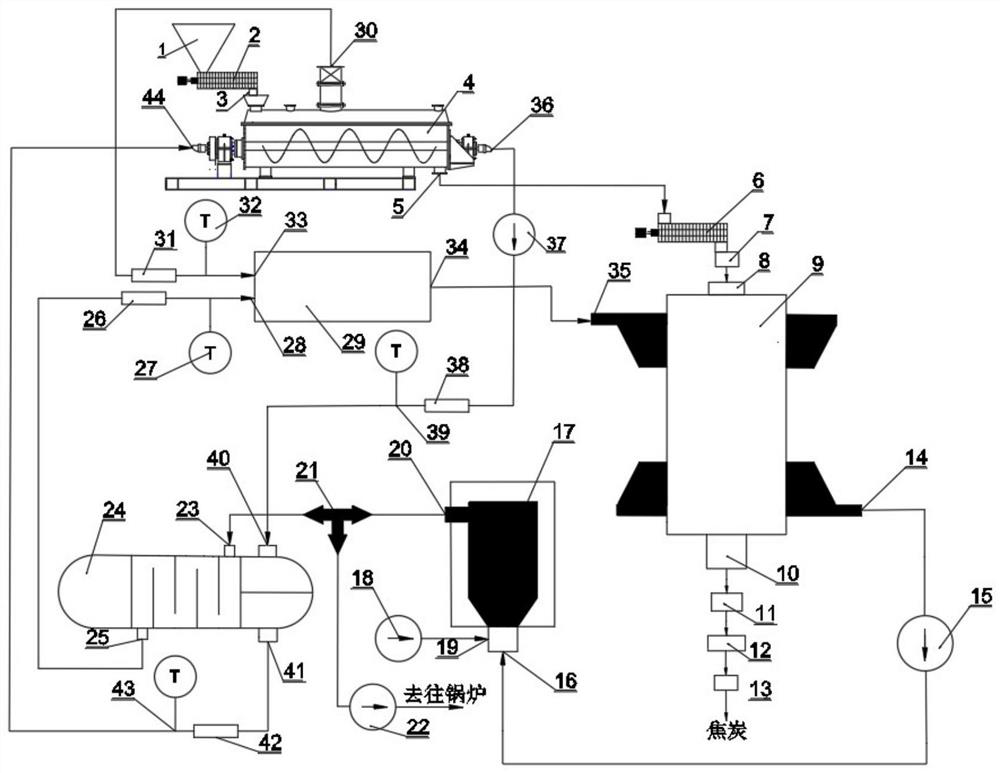

[0014] Such as figure 1 As shown, a device for preparing high-yield coke by combined roasting and carbonization includes a silo 1, a first screw feeder 2, a paddle-type roasting reactor 4, a second screw feeder 6, and a first air lock 7. Carbonization furnace 9, spiral slag discharger 11, slag cooler 12, second air locker 13, circulation fan 15, combustion chamber 17, fan 18, three-way valve 21, shell-and-tube heat exchanger 24, flow meter 26. Thermometer 27, gas mixing device 29, molten salt pump 37.

[0015] The outlet of the silo 1 is connected to the inlet 3 of the paddle-type roasting reactor 4 through the first screw feeder 2, and the outlet 5 of the paddle-type roasting reactor 4 is connected to the first lock through the second screw feeder 6 The gas device 7, the first gas locker 7 is connected to the inlet 8 of the carbonization furnace 9, the outlet 10 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com