Gas-water backwashing rapid filter tank based on modification of siphon filter tank

A siphon filter and backwashing technology, which is applied to loose filter material filters, filter separation, gravity filters, etc., can solve the problems of large water demand, long upgrading period, and occupying the filter area of the filter. The effect of the number of friction collisions, optimization of water distribution and drainage methods, and enhancement of sewage interception and regeneration capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

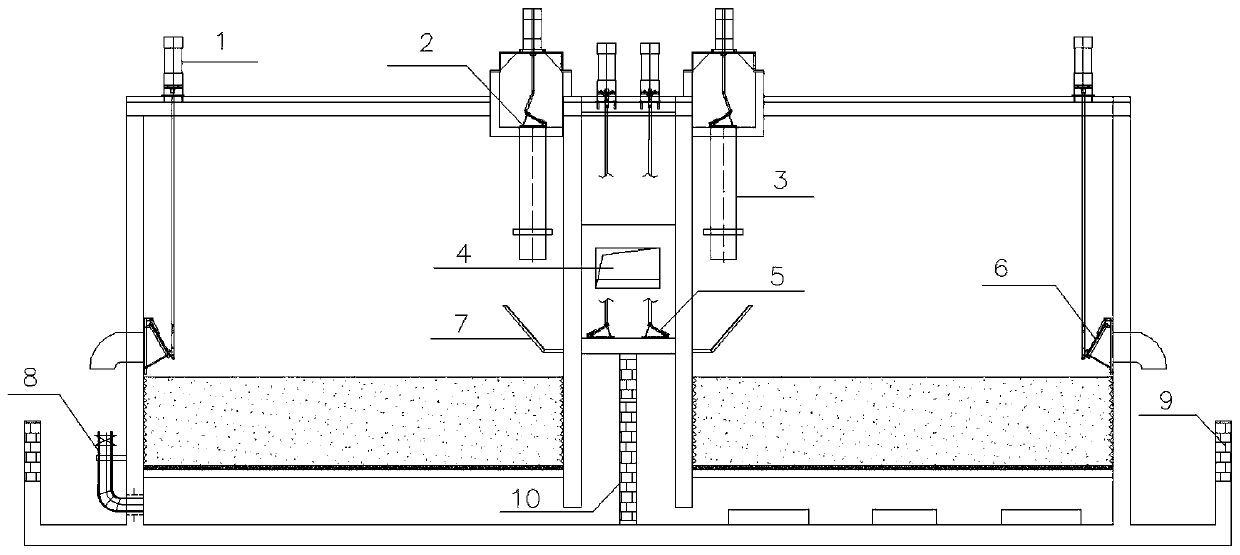

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

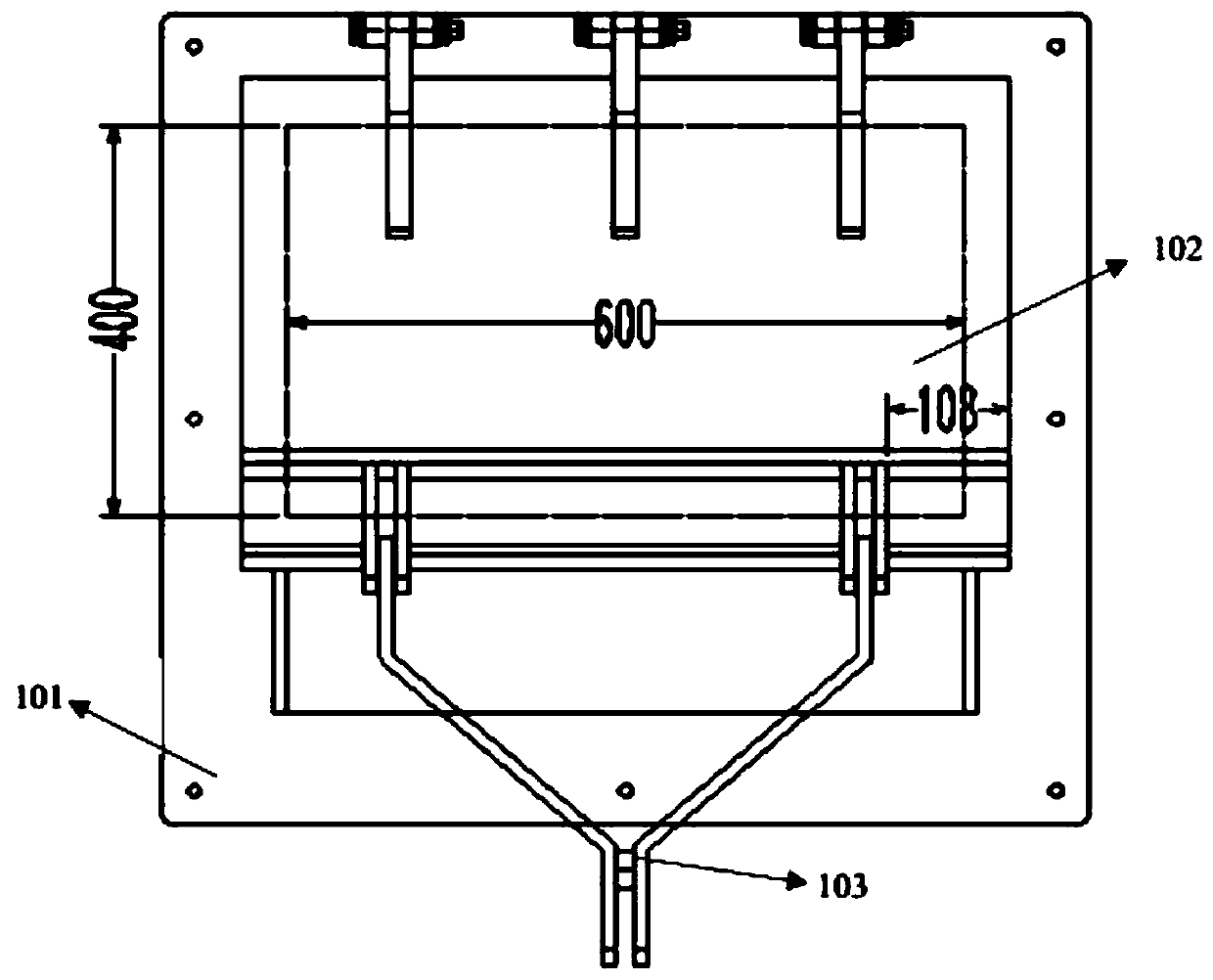

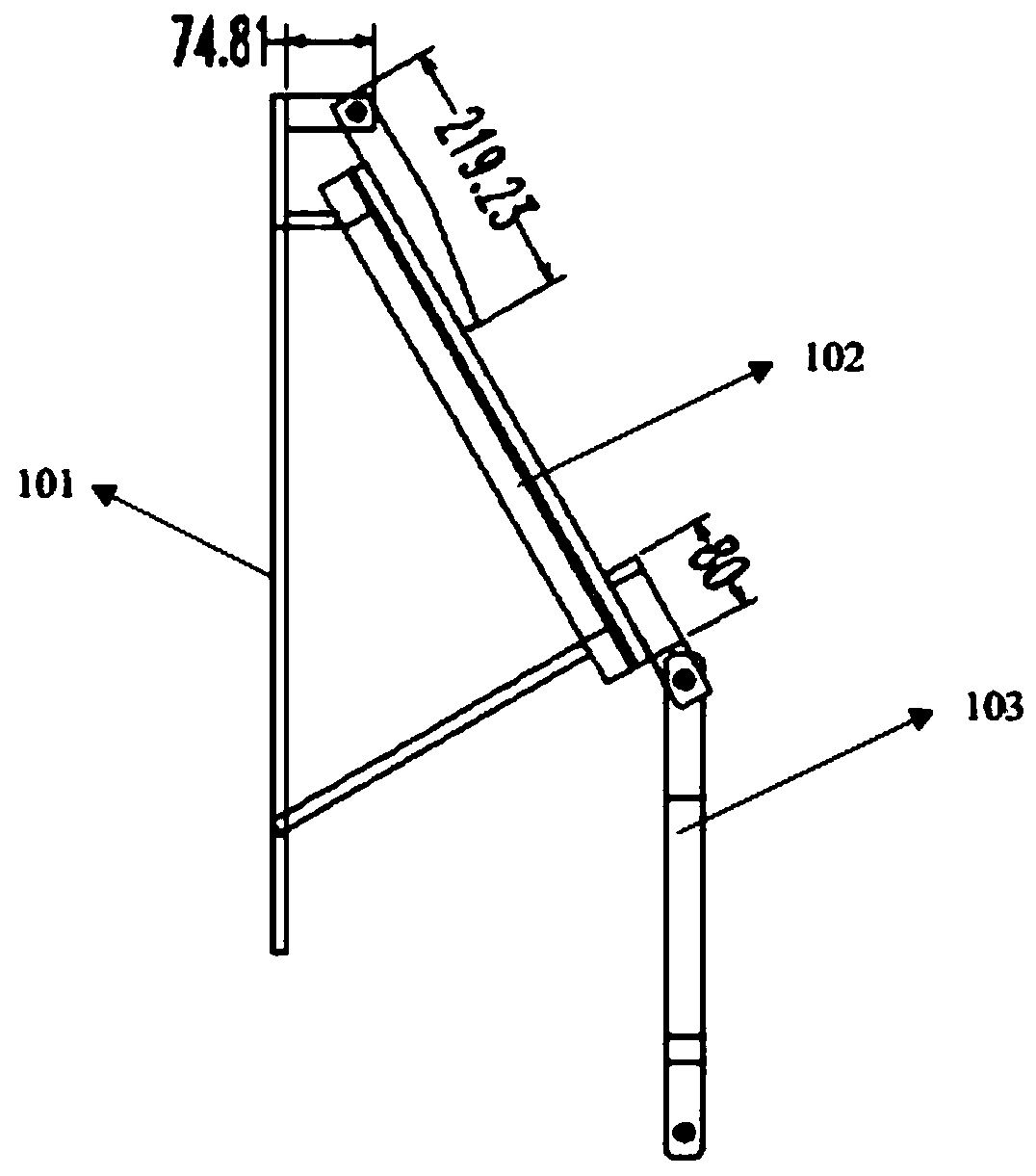

[0035] ginseng Figure 1 to Figure 4 As shown, this embodiment provides an air-water backwash fast filter based on the transformation of a siphon filter, including:

[0036] The water inlet pull valve 2 installed in the water distribution channel is used for the water inlet valve of each filter tank;

[0037] The water outlet / water flush pull plate valve 5 located on the transverse partition of the clear water channel is used for the shared valve of filter water outlet and water flush;

[0038] The drainage pull-plate valve 6 arranged on the outer pool wall of the filter is used for the drainage valve of the filter;

[0039] The overflow pull-plate valve 4 installed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com