Digital 3D implanting guide plate manufacturing method and system thereof

A guide plate, 3D technology, applied in the fields of dental implants, medical science, dentistry, etc., can solve the problem of high cost, achieve the effect of positioning improvement, reducing sliding, and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

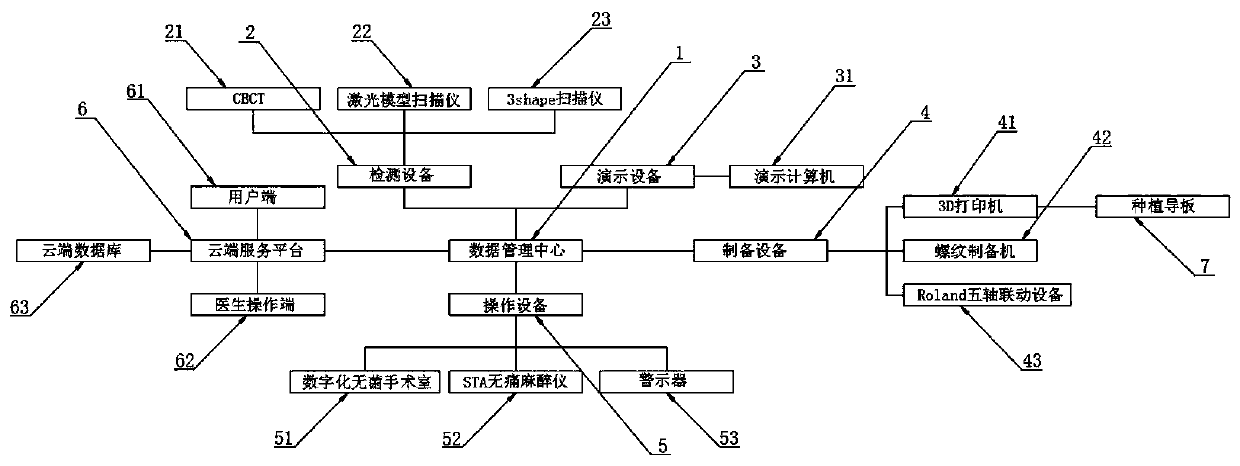

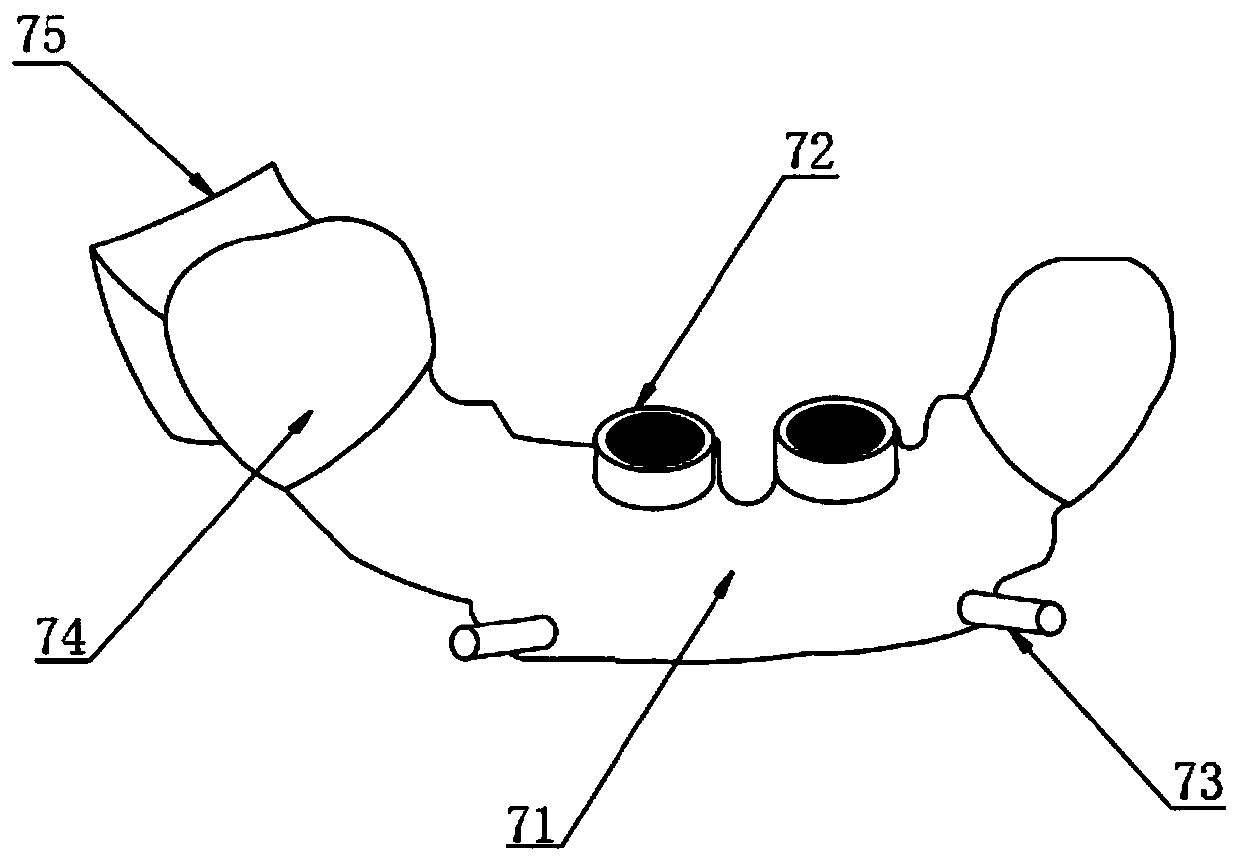

[0035] refer to Figure 1-7 The shown digital 3D planting guide plate system includes a data management center 1, and the connection end of the data management center 1 is respectively equipped with a detection device 2, a demonstration device 3, a preparation device 4, an operation device 5 and a cloud server 6. The detection device 2 includes a CBCT21, a laser model scanner 22 and a 3shape scanner 23, the demonstration device 3 includes a demonstration computer 31, and the preparation device 4 includes a 3D printer 41, a thread preparation machine 42 and a Roland five-axis linkage device 43. The operating equipment 5 includes a digital aseptic operating room 51, an STA painless anesthesia instrument 52 and a warning device 53, and the 3D printer 41 is used to make a planting guide plate 7;

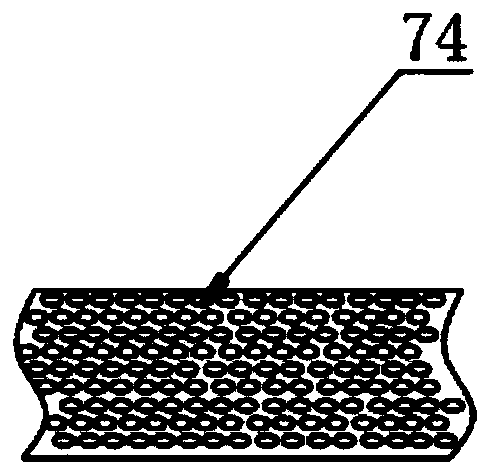

[0036] The planting guide plate 7 includes a guide plate main body 71, an implant hole 72, a positioning hole 73, an adhesive block 74, and an occlusal block 75. The top of the guide plate...

Embodiment 2

[0039] The detection device 2 is used to establish a three-dimensional model of the patient's oral cavity, and transmits the established model to the data management center 1, and the demonstration device 3 is used to demonstrate the patient model and the operation process, and can record data and transmit it to the data management center 1 , CBCT 21 in testing equipment 2 uses New Tom cone-beam CBCT, and testing equipment 2 is a complete set of systems and equipment required for digital planting.

[0040] The preparation equipment 4 is used to accept the surgical equipment model transmitted by the data management center 1 and prepare it. The thread preparation machine 42 is used to prepare implant threads and positioning threads. The implant threads match the implant holes 72. The positioning screw matches the positioning hole 73.

[0041] The operating equipment 5 is used for doctors to operate operations. The digital sterile operating room 51 includes a plurality of surgica...

Embodiment 3

[0044] The data management center 1 includes a data storage module, a data analysis module, a data processing module and a device control unit, and the data management center 1 is respectively connected with a detection device 2, a demonstration device 3, a preparation device 4 and an operation device 5 through a local area network, The data management center 1 is connected to the cloud server 6 through the Internet of Things.

[0045] The cloud server 6 connection ends are respectively provided with a user terminal 61 and a doctor operation terminal 62, and the number of the doctor operation terminals 62 is set to multiple and different doctor operation terminals 62 are provided with different login passwords, and the cloud server 6 outputs End is provided with cloud database 63.

[0046] The working process and beneficial effects of this embodiment: after the implantation is completed and before the operation, the patient can communicate with the doctor through the user term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com