Method for synchronously and efficiently extracting high-value recycled rare earth and iron in neodymium-iron-boron waste

A neodymium iron boron and waste technology is applied in the field of industrial waste recycling, which can solve the problems of neglecting the regeneration and utilization of abundant iron elements, difficult to realize high-value utilization of iron resources, and low rare earth yield, etc., and achieves high-efficiency extraction and high-value reuse. Environmentally friendly, short extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

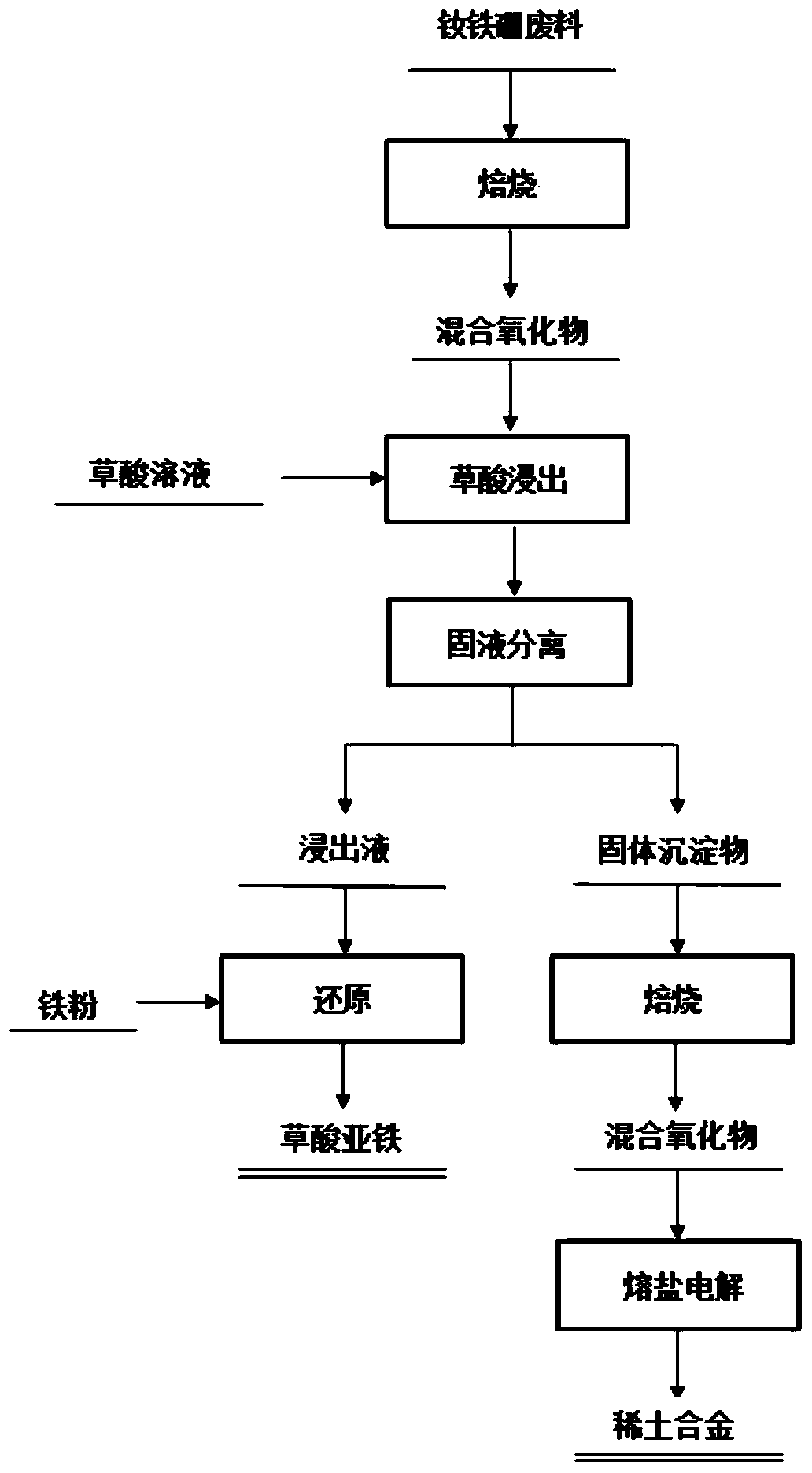

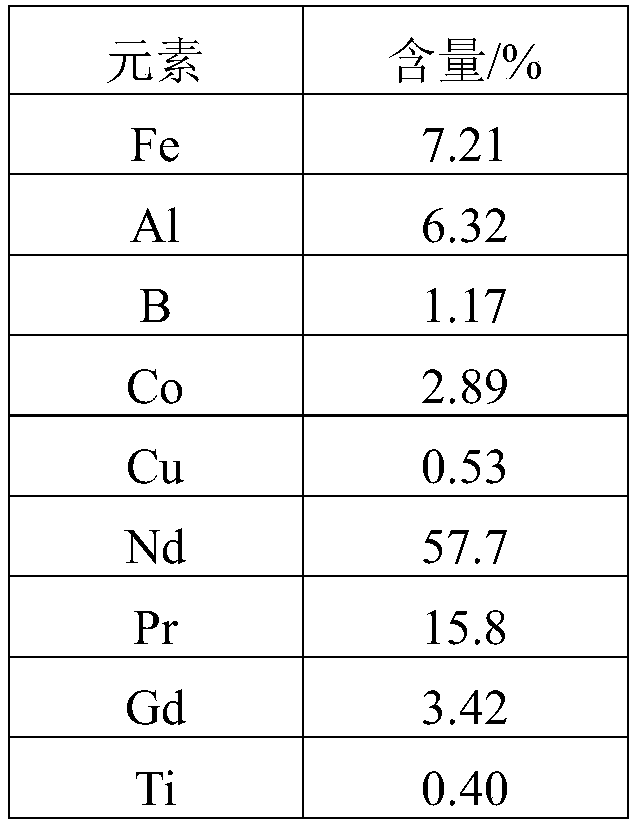

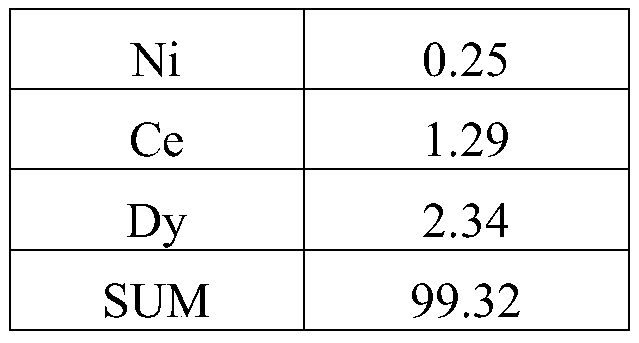

[0033] The method for synchronously and efficiently extracting rare earth and iron in high-value recycling NdFeB waste described in this embodiment includes the following steps:

[0034] (1) Take the NdFeB waste and send it to the roaster, and oxidize and roast it at 950°C for 1.5 hours to obtain a mixed oxide mainly composed of iron and rare earth, grind it until the particle size is 300 mesh, and set it aside;

[0035] (2) Take 5 g of the above-mentioned mixed oxide and oxalic acid solution with a concentration of 0.75 mol / L to react in a beaker for 2 hours according to a solid-liquid ratio of 1:50 (g / mL) to obtain a solid-liquid mixture, and set a constant temperature stirrer during the process The temperature is 90°C, and the rotation speed is 400r / min; the obtained solid-liquid mixture is filtered and separated to obtain the leachate containing iron oxalate and the solid precipitate mainly composed of rare earth oxalate;

[0036] (3) Add iron powder 2.55g in the leachate ...

Embodiment 2

[0043] The method for synchronously and efficiently extracting rare earth and iron in high-value recycling NdFeB waste described in this embodiment includes the following steps:

[0044] (1) Take the NdFeB waste material and send it to a roasting furnace, and carry out oxidation roasting at a temperature of 700 ° C for 3 hours to obtain a mixed oxide mainly composed of iron and rare earth, which is ground to a particle size of 300 mesh, and then used for later use;

[0045](2) Take 5 g of the above-mentioned mixed oxide and oxalic acid solution with a concentration of 0.5 mol / L and react in a beaker for 3 hours according to a solid-liquid ratio of 1:60 (g / mL) to obtain a solid-liquid mixture, and set a constant temperature stirrer during the process The temperature is 80°C, and the rotation speed is 400r / min; the obtained solid-liquid mixture is filtered and separated to obtain the leachate containing iron oxalate and the solid precipitate mainly composed of rare earth oxalate;...

Embodiment 3

[0053] The method for synchronously and efficiently extracting rare earth and iron in high-value recycling NdFeB waste described in this embodiment includes the following steps:

[0054] (1) Take the NdFeB waste and send it to the roaster, and oxidize and roast it at 1200 ° C for 1 hour to obtain a mixed oxide mainly composed of iron and rare earth, grind it until the particle size is 300 mesh, and set it aside;

[0055] (2) Take 5 g of the above-mentioned mixed oxide and oxalic acid solution with a concentration of 1.25 mol / L and react in a beaker for 1 hour according to the solid-liquid ratio of 1:40 (g / mL) to obtain a solid-liquid mixture. The temperature is 100°C, and the rotation speed is 400r / min; the obtained solid-liquid mixture is filtered and separated to obtain the leachate containing ferric oxalate and the solid precipitate mainly composed of rare earth oxalate;

[0056] (3) Add iron powder 2.55g in the leaching liquid that step (2) obtains, add constant temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com