Large-distortion blade precise electrolytic machining device and process method

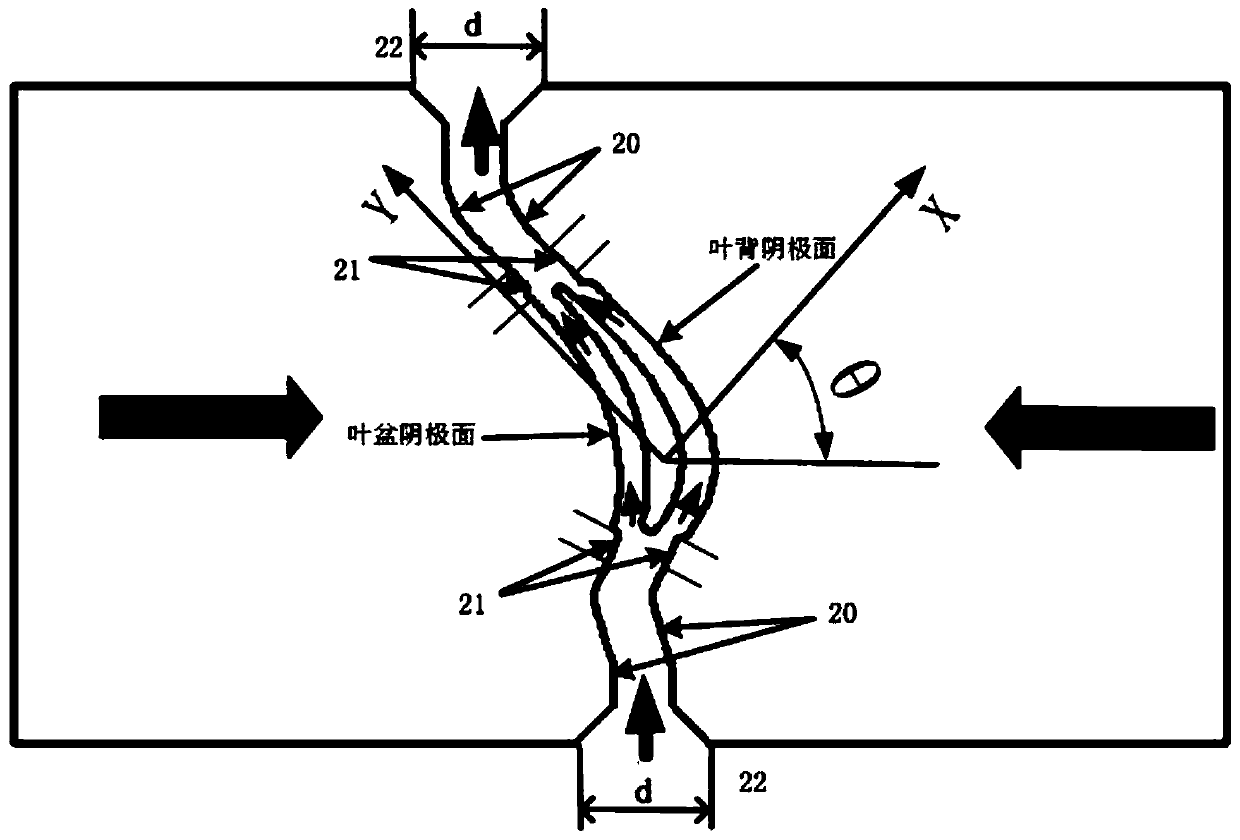

A processing device and a technology of twisted blades, which are applied in the field of precision electrolytic processing devices for large twisted blades, can solve problems such as difficulty in forming blade inlet and outlet edges, sudden changes in electrolyte flow rate, and low processing efficiency, so as to improve electrolytic forming accuracy and optimize The effect of feed angle and flow field stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples.

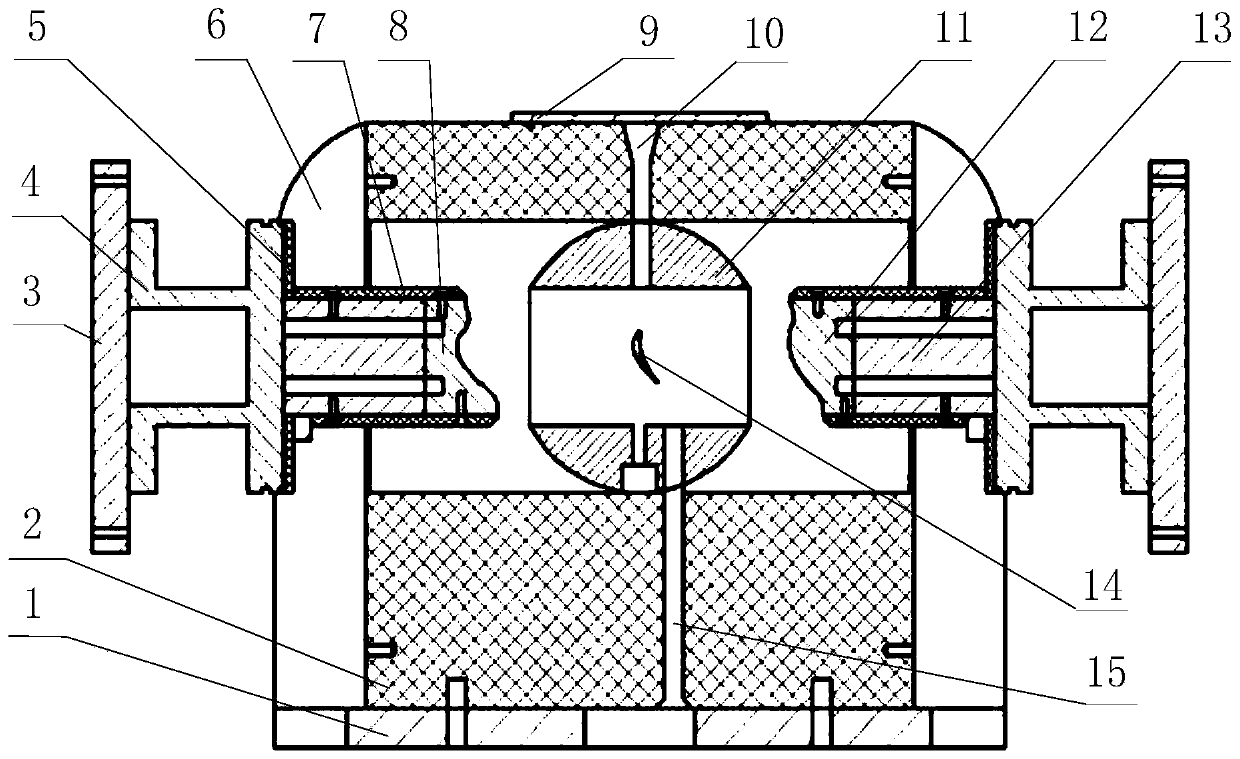

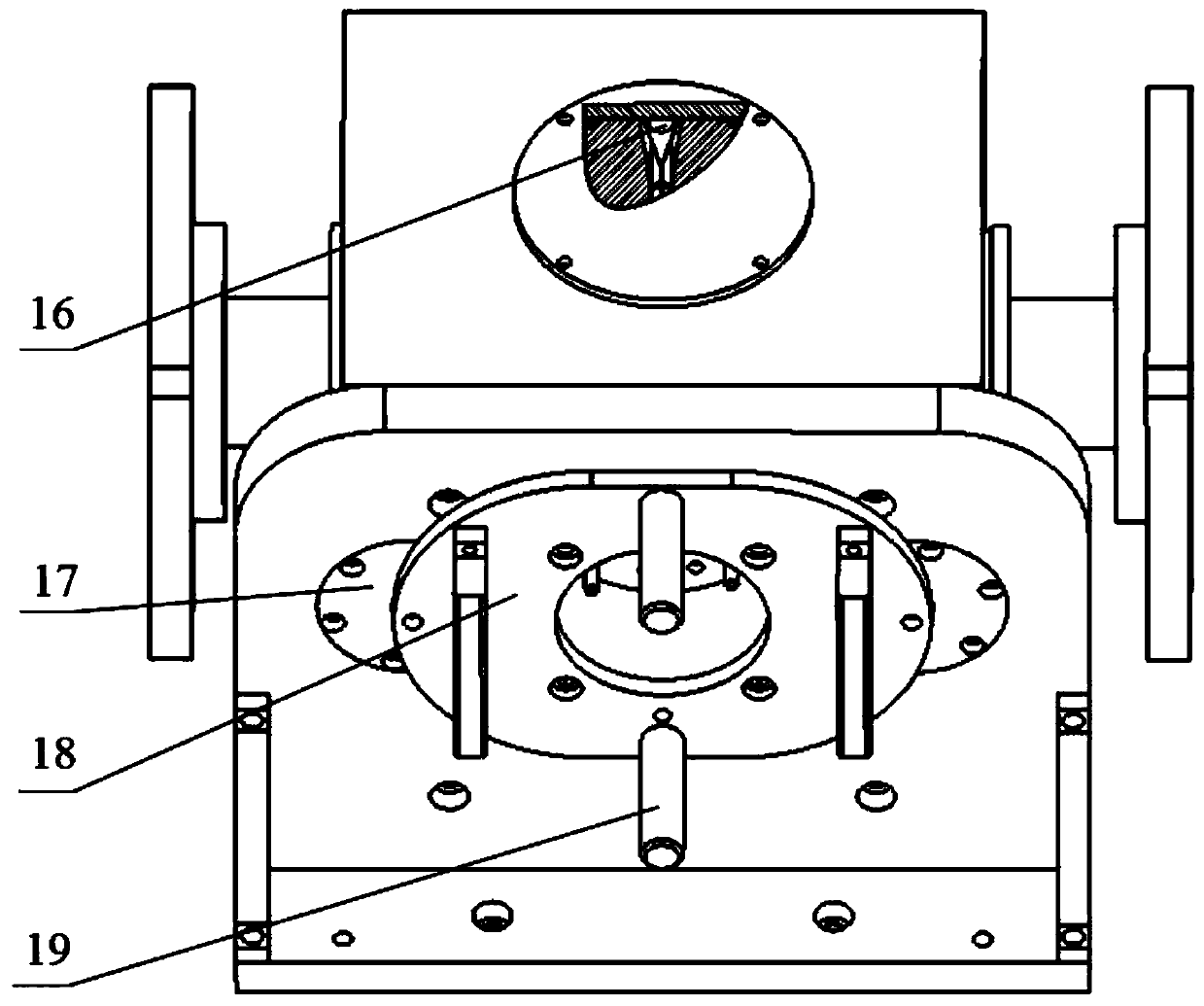

[0040]A precision electrolytic processing device for large twisted blades, including a cathode positioning and clamping device, a workpiece quick change device, and an electrolyte flow guiding device; the cathode positioning and clamping device is horizontally and symmetrically arranged on the left and right sides of the device, and the The liquid guiding device comprises a fixture base 2, a leaf pot cathode 12 and a leaf back cathode 8, the leaf pot cathode 12 and the leaf back cathode 8 are connected to the cathode positioning clamping device, the fixture base 2 and the workpiece quick change device located in the center of the device;

[0041] The cathode positioning and clamping device includes an adapter plate 3, a cathode rod 4 and a cathode connection block 13 connected in sequence, the adapter plate 3 is installed on the outside of the cathode rod 4, and the cathode co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com