Industrial oily fume purification equipment capable of intensively recovering waste oil

An oil fume purification and industrial technology, applied in chemical instruments and methods, dispersed particle filtration, gas treatment, etc., can solve the problems of unfavorable unified management, waste of material resources, unfavorable management and recovery of waste oil, etc., achieve good purification effect, save material resources, Good for management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

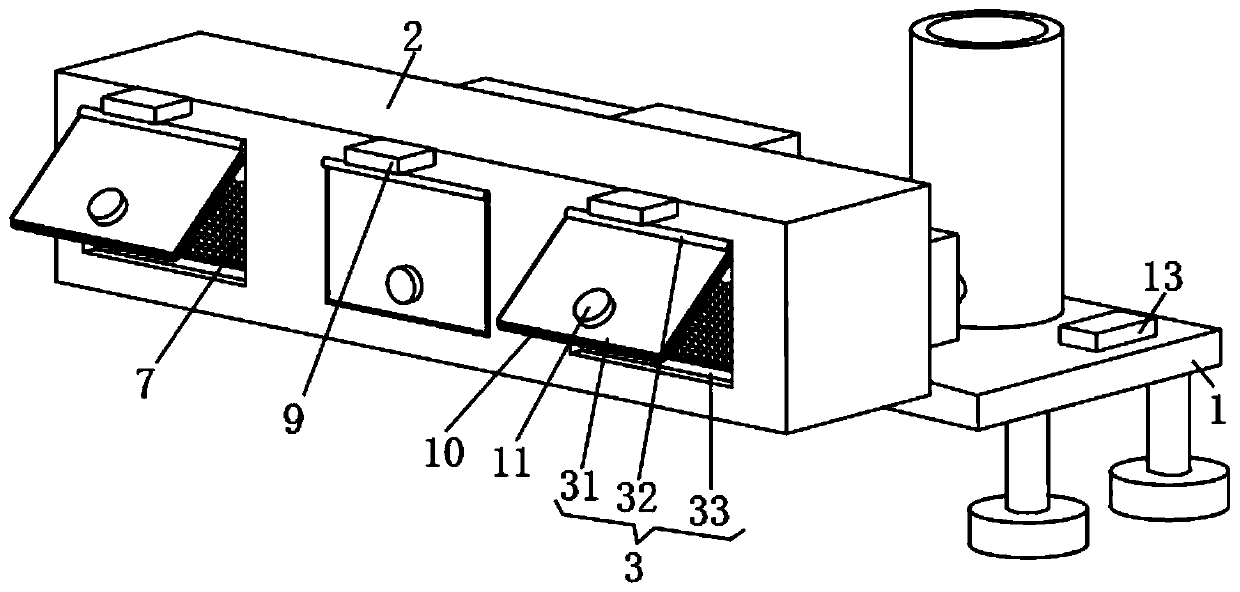

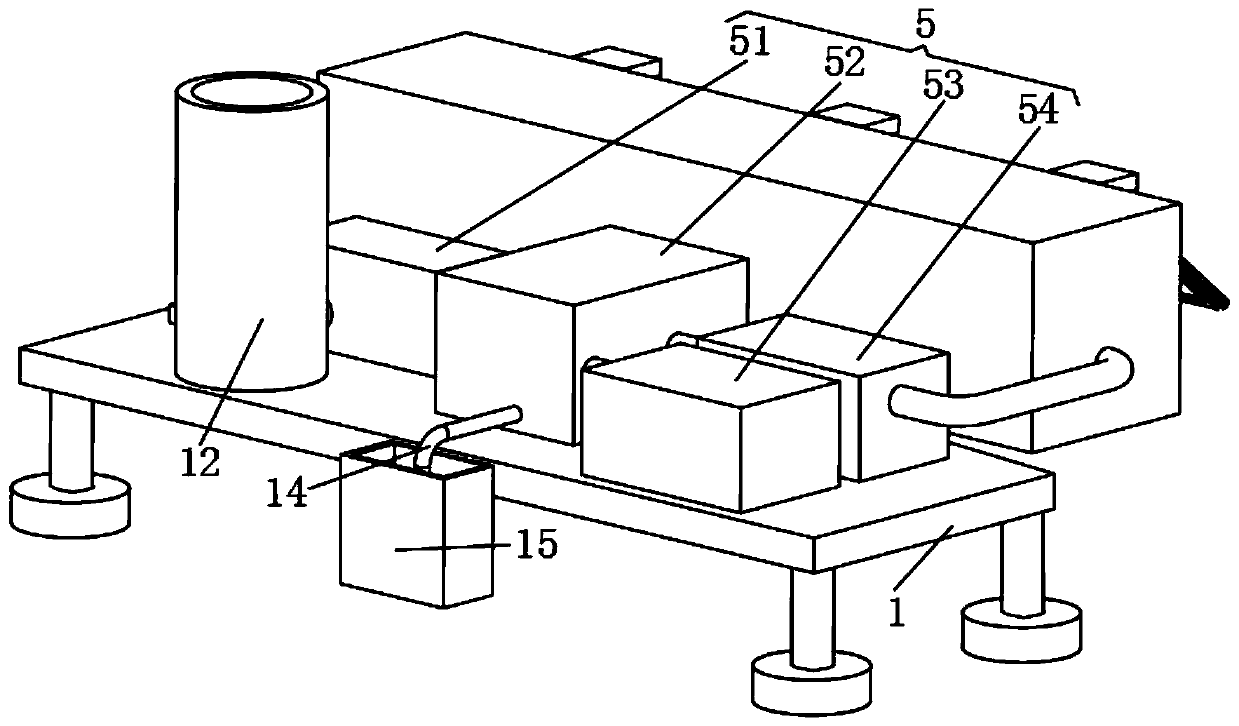

[0025] Such as figure 1 and 2 , an industrial oil fume purification equipment that can centrally recover waste oil, is characterized in that it includes a mounting plate 1, an air intake box 2, a collection unit 3 and a processing unit 5, the mounting plate 1 is a cuboid, and the four corners of the lower surface of the mounting plate 1 are uniform A bracket is provided, the lower end of the bracket is provided with a base, the air intake box 2 is a cuboid, and the front side wall of the air intake box 2 is equidistantly provided with three air intake slots, and the collection unit 3 includes a box door 31, a rotating shaft 32 and a second One electromagnet 33, described box door 31 is three, and is respectively placed in the air intake groove of air intake box 2 front side walls, and the upper end of box door 31 is connected with air intake box 2 by rotating shaft 32 rotations, and the first electromagnet There are three irons 33, and they are placed on the side wall of the ...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is:

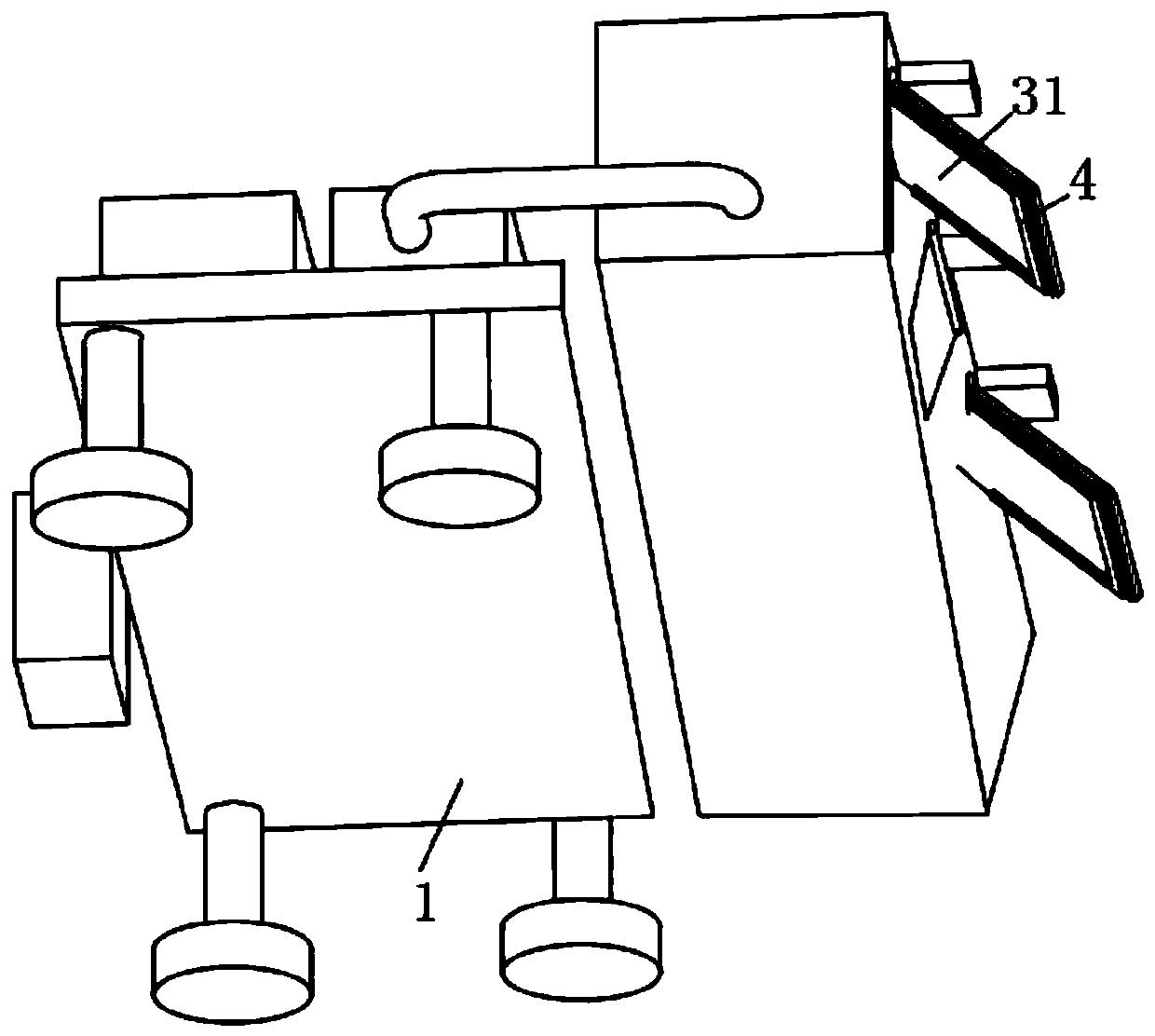

[0028] In the present embodiment, there are three sieve plates 7, and they are respectively placed in three air intake slots, the sieve plate 7 is fixedly connected with the air intake box 2, and the oleophobic layer 8 is a PTFE layer, such as Figure 4 , the oleophobic layer 8 is placed on the inner side wall of the air intake box 2, the oleophobic layer 8 is fixedly connected with the air intake box 2, and there are three baffle plates 9, which are respectively placed on the front side wall of the air intake box 2 and the box door 31 In the corresponding position, the baffle plate 9 is fixedly connected with the air intake box 2 .

[0029] Specifically, the sieve plate 7 can prevent large particles of impurities from entering the air intake box 2, the oleophobic layer 8 can be used to prevent the oil in the oil fume from being adsorbed on the inner wall of the air intake box 2, and the baffle plate 9 can be...

Embodiment 3

[0031] The difference between this embodiment and Embodiment 1 is:

[0032] In this example, if figure 1 , there are three sealing rings 10, which are respectively placed on the side walls of the three box doors 31, and are fixedly connected between the sealing rings 10 and the box doors 31, such as figure 2 , the exhaust tower 12 is placed on the upper surface of the mounting plate 1, the air inlet of the exhaust tower 12 is connected to the gas outlet of the oil removal tank 52 through a connecting pipe, the waste oil tank 15 is placed on the side wall of the mounting plate 1, and one end of the oil outlet pipe 14 Placed at the lower end of the oil removal tank 52 , the oil outlet pipe 14 communicates with the inside of the oil removal tank 52 , and the other end of the oil outlet pipe 14 is placed in the waste oil tank 15 .

[0033] Specifically, the sealing ring 10 can be used to prevent air leakage at the box door 31, the exhaust tower 12 can be used to discharge the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com