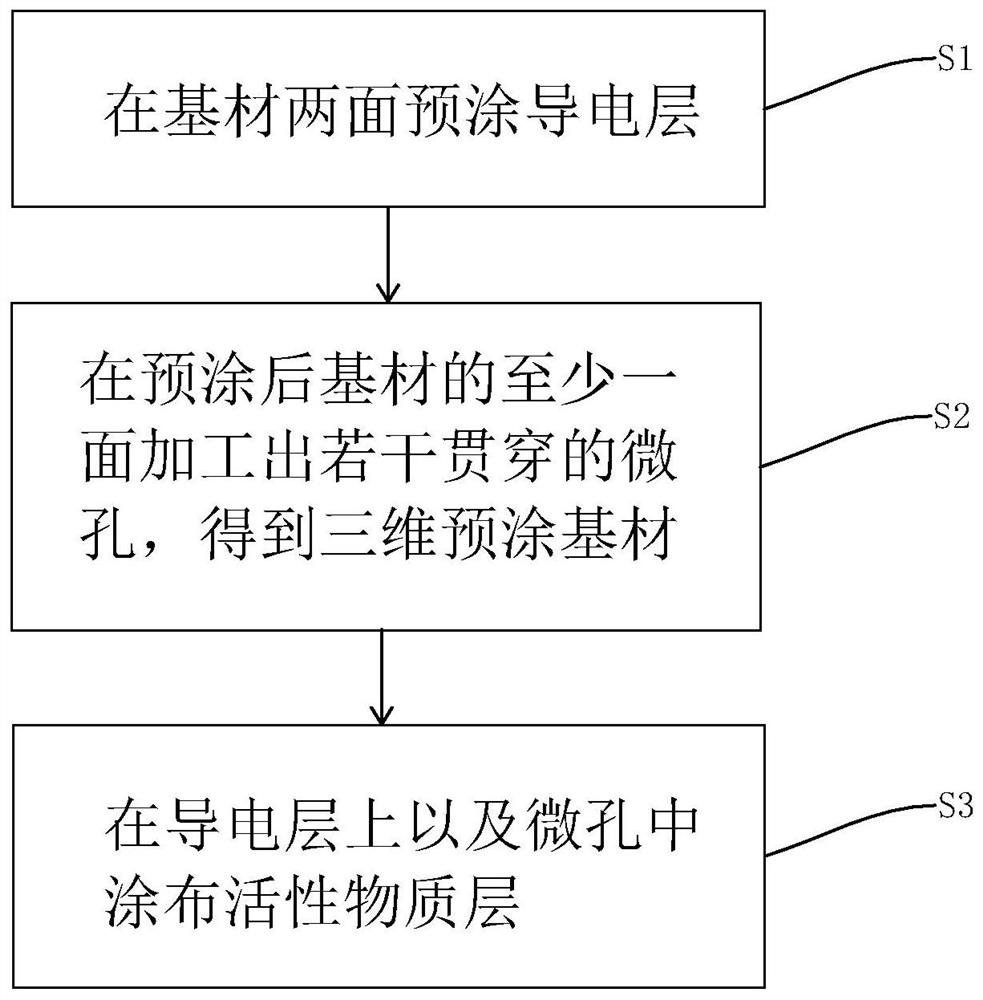

A double-sided coating integrated three-dimensional substrate manufacturing method and manufacturing equipment

A technology for manufacturing equipment and substrates, applied in electrode manufacturing, electrode rolling/calendering, electrode collector coating, etc., which can solve the problems of difficult control of coating uniformity and coating thickness, uneven distribution of conductive paste, Affect the passage of conductive ions, etc., to improve injection efficiency and moisture drying efficiency, reduce defect generation, and ensure the effect of bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

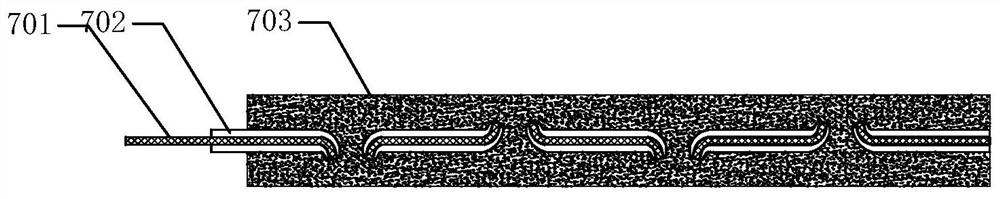

[0070] The positive electrode aluminum foil has a thickness of 12 μm, and a CNT conductive layer with a diameter of 6 to 10 nm and a length of 500 nm is pre-coated on both sides, and a thickness of 1 μm is pre-coated on one side. The thickness of the negative electrode copper foil is 8 μm, and the material and thickness of the conductive layer pre-coated on both sides of the copper foil are the same as those of the positive electrode.

[0071] The burr micro-holes are rolled on both sides of the pre-coated foil, with a pore size of 30-40 μm and a pore density of 50 pcs / mm 2 , the porosity is 5%, and the burr height on one side is 50μm. Then, the active material is coated on the surface of the pre-coated foil with micropores by extrusion coating, and then dried, rolled, slit, and die-cut to make positive and negative electrodes.

[0072] Among them, the positive electrode active material is lithium iron phosphate, accounting for 90-95%, the binder uses PVDF, accounting for 2-5...

example 2

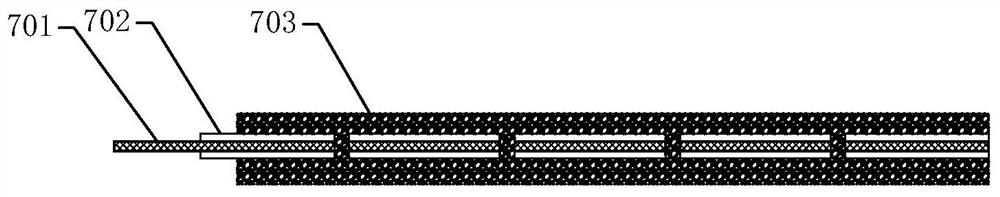

[0074] Based on Example 1, the difference is that the positive and negative micropores are all burr-free micropores (i.e., plane holes), and the pore diameter, pore density and porosity are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com