Waste heat boiler vibration control system and method

A waste heat boiler and control system technology, applied in general control system, control/regulation system, program control, etc., can solve problems such as unsatisfactory rapping effect, adjustment of rapping grouping or sequence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

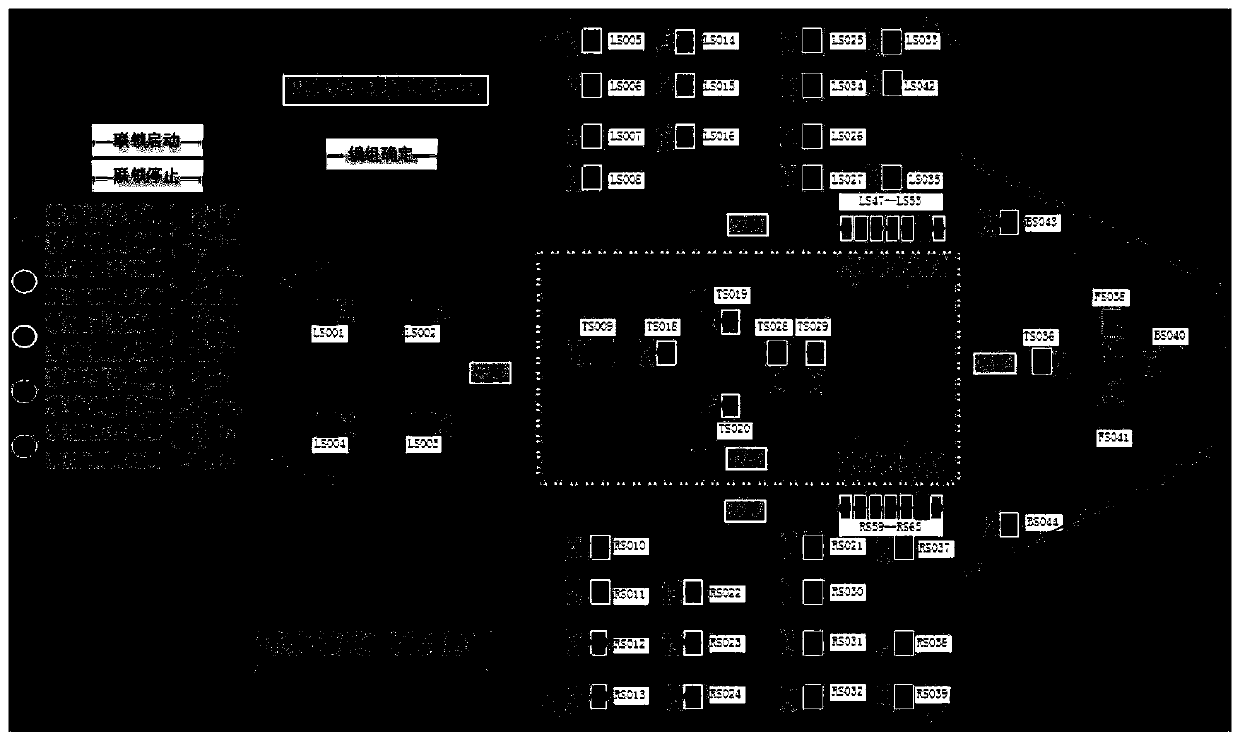

[0028] This embodiment provides a waste heat boiler rapping control system, such as figure 1 shown, including:

[0029] Waste heat boiler: equipped with several spring hammer rapping devices, all spring hammer rapping devices are divided into several rapping groups, and the rapping time and interval time of each group of rapping groups can be adjusted independently;

[0030] Further, in this embodiment, the waste heat boiler includes a radiation part and a convection part, and the radiation part and the convection part are respectively provided with several spring hammer rapping devices, and the rapping groups in the radiation part and the convection part The rapping groups of each form an independent rapping cycle.

[0031] Taking the medium-sized flash furnace waste heat boiler as an example, five rapping groups are set in the radiation part, and three rapping groups are set in the convection part. In the radiation part, the vibration is cyclically rapped in the order of 1...

Embodiment 2

[0045] This embodiment provides a method for utilizing the waste heat boiler rapping control system as described in Embodiment 1, including the following steps:

[0046] S1. When the automatic rapping mode is required, the craftsmen set the rapping points of each spring hammer rapping device on the automatic rapping arrangement interface through the group input module according to the production process conditions and the distribution of boiler ash group, and set the rapping time and interval time of each rapping group by setting the input module;

[0047] S2. The HMI rapping control device sends the rapping group to which each spring hammer rapping device belongs, the rapping time and interval time of each group of rapping groups set on the automatic rapping arrangement interface by the technician to the PLC controller;

[0048] S3. The PLC controller controls each rapping group to start rapping in order according to the rapping group to which each spring hammer rapping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com