Ash-cleaning mechanical air cooler

A technology of mechanical air cooling and ash cleaning mechanism, which is applied in the field of ash cleaning type mechanical air cooler and high temperature flue gas cooling, can solve the problems of inability to eliminate, low heat transfer coefficient and large cooling area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

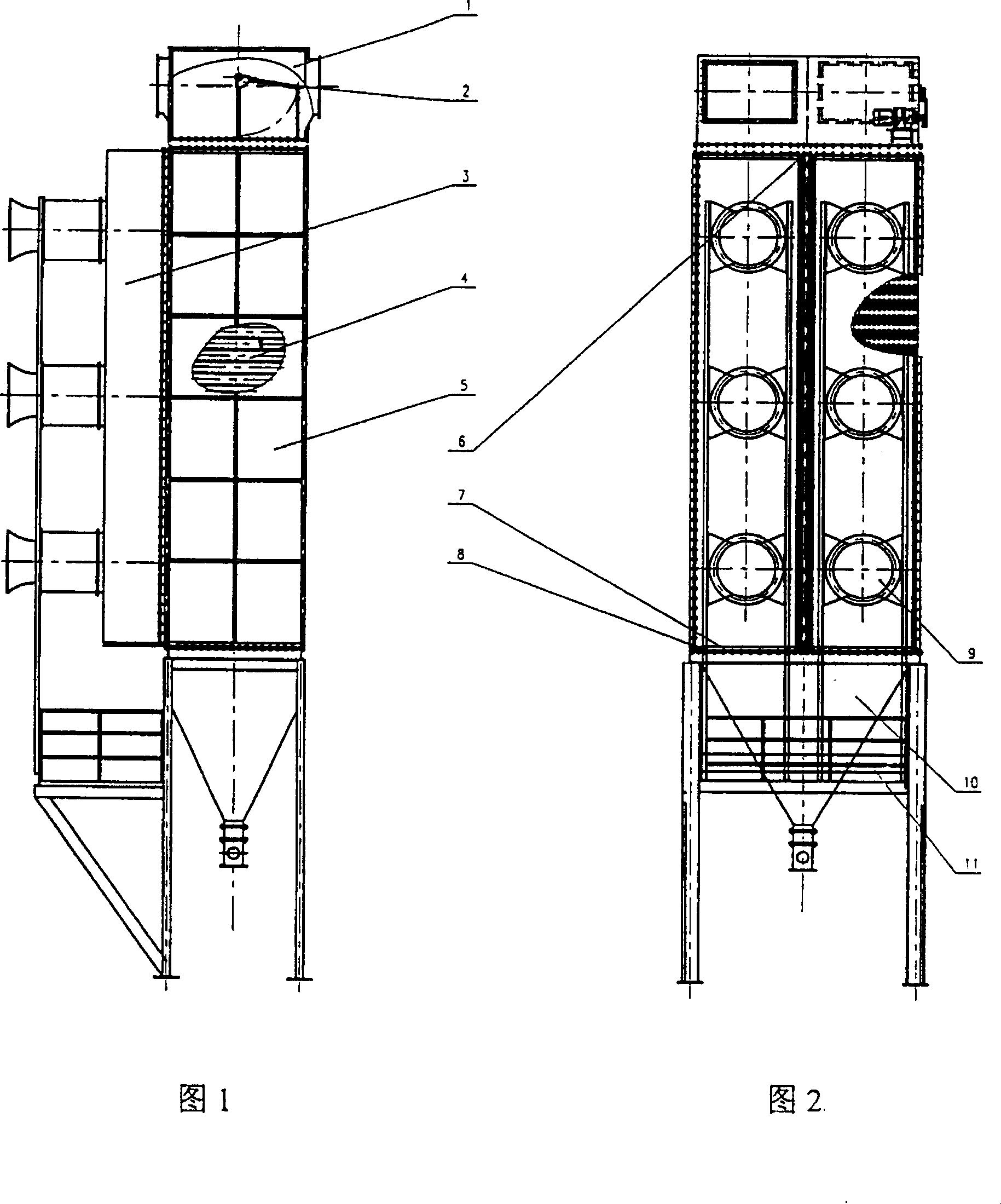

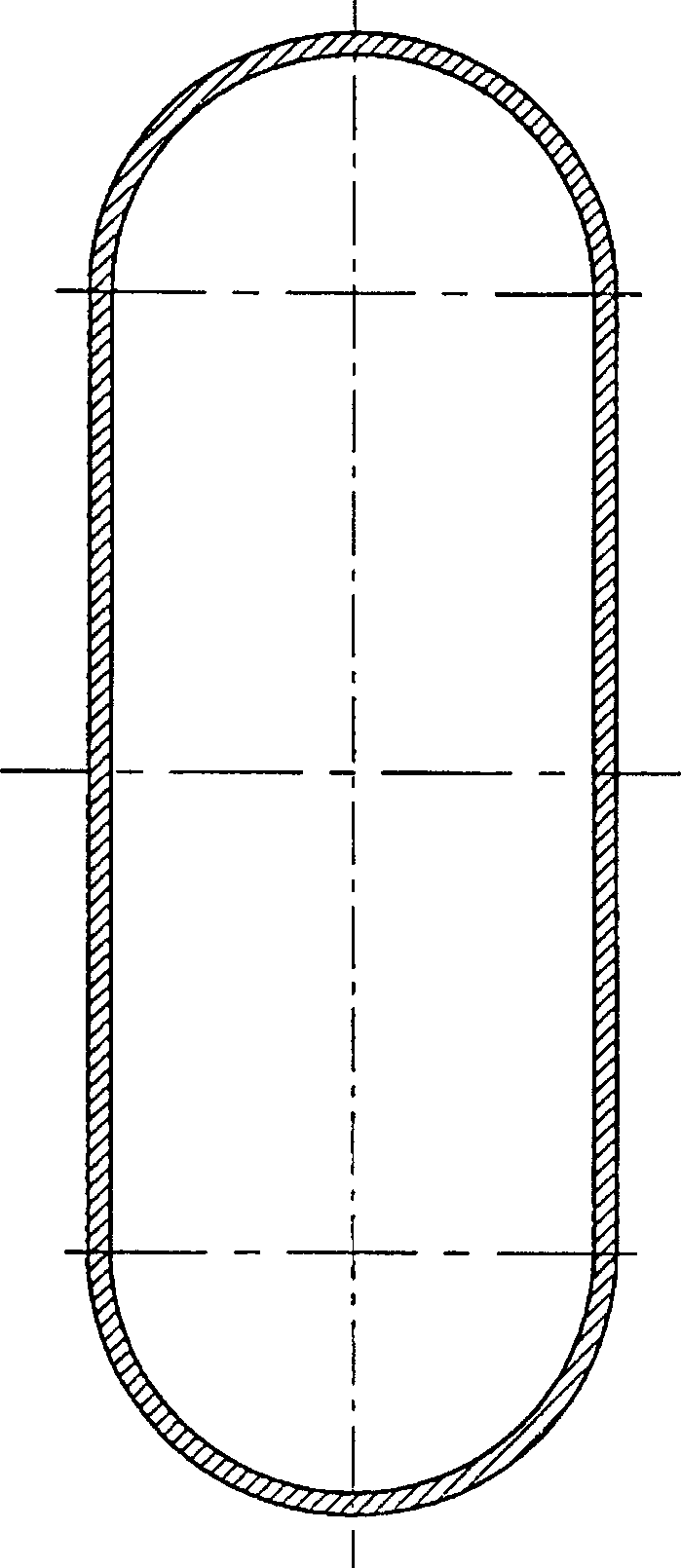

[0012] The main part of the present invention is mainly composed of header 1, dust cleaning mechanism 2, fan 3, heat dissipation pipe 4, side wall plate 5, middle partition plate 6, ash bucket ring beam 7, mixed flow fan 9, ash bucket part 10, support platform 11 composed of. The header box 1 and the dust cleaning mechanism 2 are connected and assembled together for the entry and exit of flue gas. These two parts are installed on the heat dissipation pipe 4. An air inlet is formed on the back of the right side of the header box 1. Side wall panels are installed on both sides of the heat dissipation pipe 4. 5. An intermediate partition 6 is installed in the middle, and a fan 3 and a plurality of mixed-flow fans 9 are installed on the other side of the heat dissipation pipe 4 for blowing cooling air into the heat dissipation pipe 4 . A plurality of heat dissipation pipes 4 are used to form a heat dissipation pipe group, and several heat dissipation pipes 4 are installed in paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com