Engine exhaust waste heat recovery system

A waste heat recovery and engine technology, which is applied in the direction of engine components, combustion engines, engine cooling, etc., can solve the problems of increasing costs and unfavorable weight reduction of automobiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

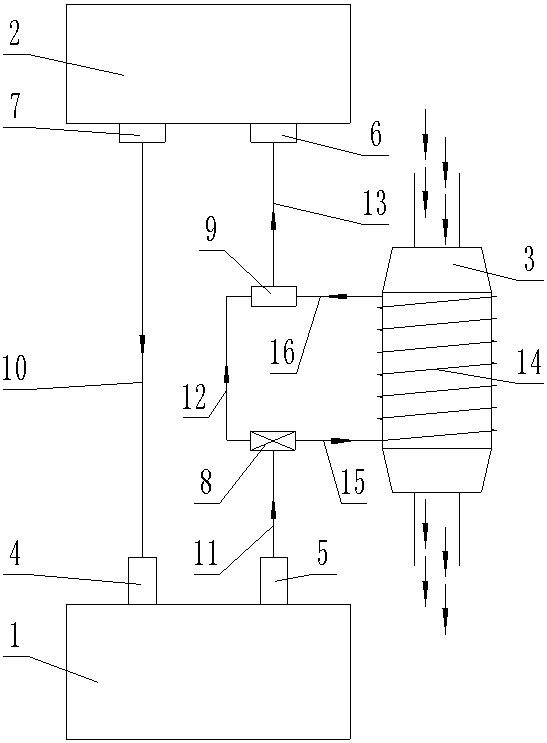

[0017] The present invention will be further described below in conjunction with accompanying drawing.

[0018] Such as figure 1 The shown engine exhaust waste heat recovery system includes an engine 1, a heater 2, an automobile exhaust catalyst 3, a thermostat 8, a tee joint 9 and a heat exchange element 14; the engine 1 is provided with an engine water inlet 4 and the engine water outlet 5; the heater 2 is provided with a heater water inlet 6 and a heater outlet 7; the thermostat 8 is provided with a thermostat water inlet, a first thermostat outlet and a second thermostat Water outlet; the heat exchange element 14 is arranged on the periphery of the automobile exhaust catalytic converter 3, the heat exchange element 14 is provided with a heat exchange element water inlet and a heat exchange element water outlet, and the heat exchange element 14 is provided with a water inlet connected to the heat exchange element and The liquid flow path of the water outlet of the heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com