Thermal activation delayed fluorescent material, preparation method thereof and electroluminescent device

An electroluminescence device, thermal activation delay technology, applied in the direction of luminescent materials, electric solid devices, chemical instruments and methods, etc., can solve the problem of lack of thermal activation delay fluorescent materials, etc., to achieve easy purification, high yield, high luminescence efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An embodiment of the present invention provides a thermally activated delayed fluorescent material. The thermally activated delayed fluorescent material includes an electron donor and an electron acceptor, and the electron acceptor has an azaaromatic ring structure and is connected to the aza The diphenylamine structure and the tetramethylbenzene structure of the aromatic ring structure have a general structural formula:

[0039]

[0040] Wherein, in the general structural formula of the thermally activated delayed fluorescent material, R is an aromatic compound, and its structure is:

[0041]

[0042] Specifically, in the embodiment of the present invention, the general structural formula of the thermally activated delayed fluorescent material is:

[0043]

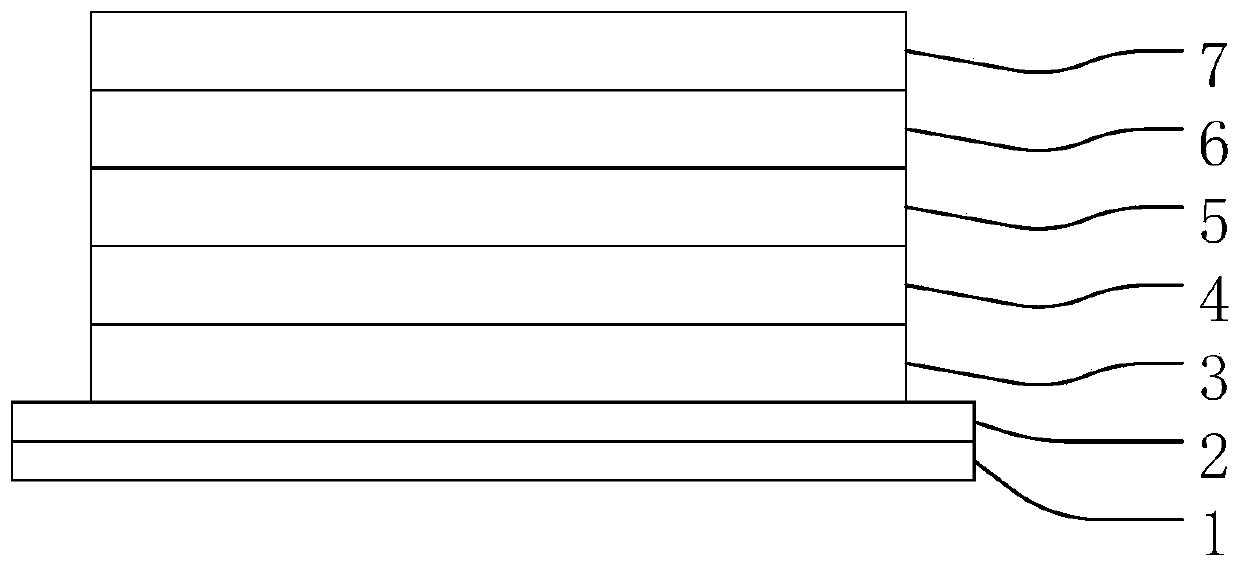

[0044] The embodiment of the present invention also provides a preparation method of thermally activated delayed fluorescent material, the preparation process is as follows figure 1 As shown, the specific...

Embodiment 2

[0052] An embodiment of the present invention provides a thermally activated delayed fluorescent material. The thermally activated delayed fluorescent material includes an electron donor and an electron acceptor, and the electron acceptor has an azaaromatic ring structure and is connected to the aza The diphenylamine structure and the tetramethylbenzene structure of the aromatic ring structure have a general structural formula:

[0053]

[0054] Wherein, in the general structural formula of the thermally activated delayed fluorescent material, R is an aromatic compound, and its structure is:

[0055]

[0056] Specifically, in the embodiment of the present invention, the general structural formula of the thermally activated delayed fluorescent material is:

[0057]

[0058] The embodiment of the present invention also provides a preparation method of thermally activated delayed fluorescent material, the preparation process is as follows figure 1 As shown, the specific...

Embodiment 3

[0066] An embodiment of the present invention provides a thermally activated delayed fluorescent material. The thermally activated delayed fluorescent material includes an electron donor and an electron acceptor, and the electron acceptor has an azaaromatic ring structure and is connected to the aza The diphenylamine structure and the tetramethylbenzene structure of the aromatic ring structure have a general structural formula:

[0067]

[0068] Wherein, in the general structural formula of the thermally activated delayed fluorescent material, R is an aromatic compound, and its structure is:

[0069]

[0070] Specifically, in the embodiment of the present invention, the general structural formula of the thermally activated delayed fluorescent material is:

[0071]

[0072] The embodiment of the present invention also provides a preparation method of thermally activated delayed fluorescent material, the preparation process is as follows figure 1 As shown, the specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com