Sheet metal conveying release agent and preparation method thereof

A metal sheet and release agent technology, used in paints, coatings, antifouling/underwater coatings containing biocides, etc., which can solve the problem that metal sheets and conveyor belts are prone to adhesion, copper sheet conveyor belts fall off automatically, and affect the transportation effect. and other problems, to achieve excellent isolation effect, improve finish, and improve the effect of isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

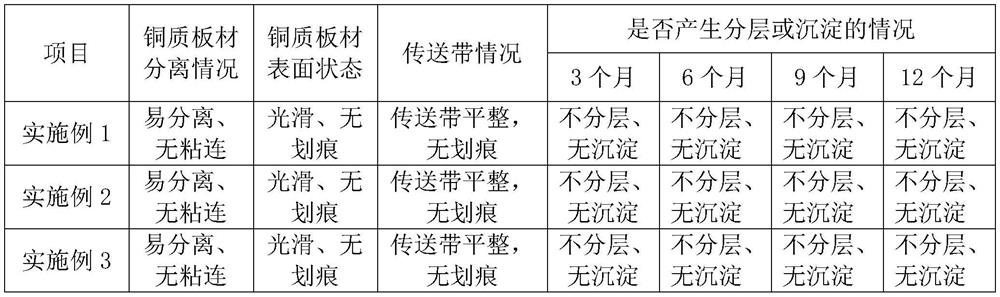

Examples

Embodiment 1

[0036] Embodiment 1: A kind of sheet metal conveying isolating agent adopts the following method to prepare: comprise the following steps: add microcrystalline cellulose 20kg, sodium carboxymethyl cellulose 12kg, gum arabic 20kg, sodium polyacrylate 4kg, 270kg of flake graphite, 40kg of high wear-resistant furnace black, 80kg of activated carbon, 4kg of 1,2-benzisothiazolin-3-one and 20kg of ammonia water. After stirring at a speed of 30-50 minutes, a metal sheet conveying release agent is obtained.

Embodiment 2-6

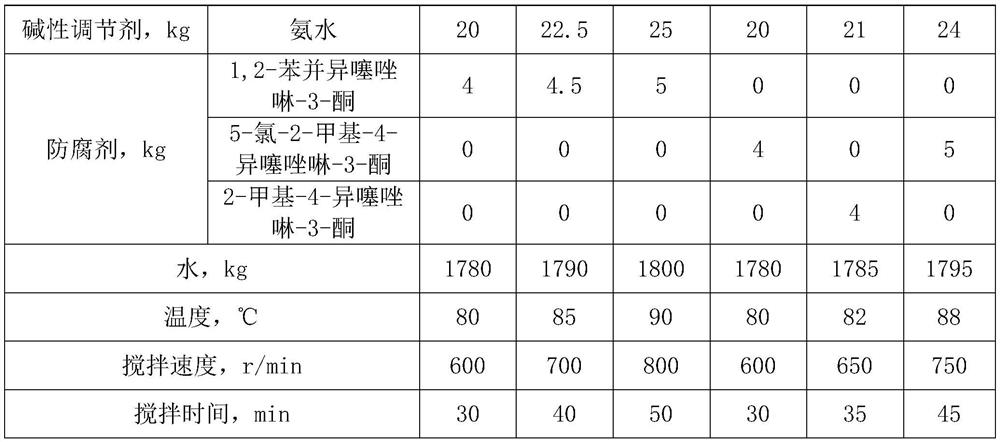

[0038] According to the preparation method described in Example 1, the difference is that the parameters shown in Table 1 are used for the raw materials, dosage and process parameters.

[0039] Table 1

[0040]

[0041]

[0042] 2. Comparison ratio

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com