Modified PMMA, preparation method thereof and preparation method of high-specific capacity flame-retardant lithium battery membrane by using modified PMMA

A lithium battery diaphragm and high specific capacity technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of space waste and energy density reduction, and achieve the effect of low price, high strength, and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

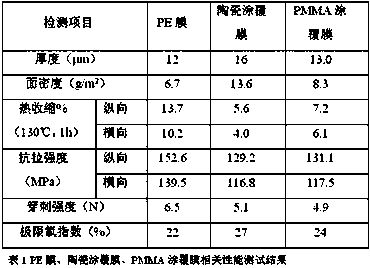

Image

Examples

Embodiment 1

[0028] (1) Weigh 3g of guanidine sulfamate and dissolve it in a mixed solvent of 100g of water and ethanol (water:ethanol=1:1), and dissolve evenly under mechanical stirring;

[0029] (2) Under N2 environment, transfer the above mixed solution to an ultrasonic bath, add 0.1% initiator AIBN, add 10g methyl methacrylate and heat to 65°C for 3.5 hours until the reaction solution is completely reacted to obtain sulfamic acid Guanidine modified PMMA mixture;

[0030] (3) Wash the modified PMMA mixture with water and alcohol, filter it with suction and dry it;

[0031] (4) The dried modified PMMA was dissolved and evenly coated on the PE separator, washed with water and then dried to obtain sample 1.

Embodiment 2

[0033] (1) Weigh 5g of guanidine phosphate and dissolve in 100g of water and acetone mixed solvent (water: acetone = 3:1), and dissolve evenly under mechanical stirring;

[0034] (2) Under the N2 environment, transfer the above mixed solution to an ultrasonic bath, add 0.1% initiator AIBN, add 20g methyl methacrylate and heat to 60°C for 3 hours until the reaction solution is completely reacted to obtain the modified guanidine phosphate Sexual PMMA mixture;

[0035] (3) Wash the modified PMMA mixture with water and alcohol, filter it with suction and dry it;

[0036] (4) The dried modified PMMA was dissolved and evenly coated on the PE separator, washed with water and then dried to obtain sample 2.

Embodiment 3

[0038] (1) Weigh 3g of guanidine sulfonate and dissolve it in 100g of water and methanol mixed solvent (water: methanol = 1:1), and dissolve evenly under mechanical stirring;

[0039](2) Under N2 environment, transfer the above mixed solution to an ultrasonic bath, add 0.1% initiator AIBN, then gradually add 20g of 3,3-methyl methacrylate and heat to 65°C for 3 hours until the reaction solution is completely reacted , obtain guanidine sulfonate modified PMMA mixed solution;

[0040] (3) Wash the modified PMMA mixture with water and alcohol, filter it with suction and dry it;

[0041] (4) The dried modified PMMA was dissolved and evenly coated on the PE separator, and the prepared modified PMMA mixture was coated on the PE separator, washed with water and then dried to obtain sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com