Polyurethane resin for bonding layer and preparation method for polyurethane resin

A technology of polyurethane resin and bonding layer, applied in the field of polyurethane materials, can solve the problems of delamination and pulverization, rapid decline of bonding strength, insufficient bonding strength of polyurethane resin and cloth base, etc., and achieves high hydrolysis resistance, stable quality and improved, The effect of high peel strength retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

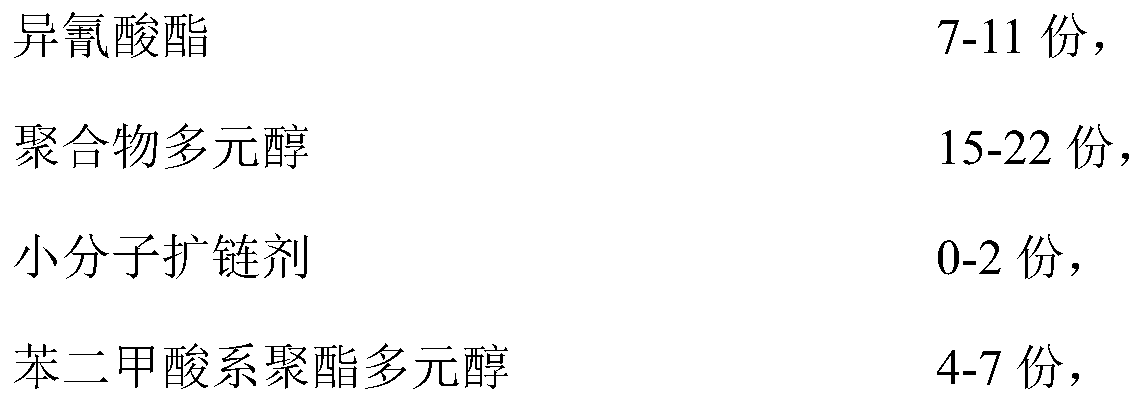

Method used

Image

Examples

Embodiment 1

[0035] The bonding layer in the present embodiment uses polyurethane resin, and raw material composition and addition are shown in the following table:

[0036] raw material name Weight (unit: g) 4,4′-Diphenylmethane diisocyanate (MDI) 378 Polyether polyol (PTMG-2) 420 Polyether polyol (PTMG-1) 280 Phthalate-based polyester diol (Amway SP-2260) 260 Antioxidant UHS-301 0.3 Organic Bismuth Catalyst (MB20) 0.1 N,N-Dimethylformamide (DMF) 3120

[0037] In the present embodiment, the preparation steps of the polyurethane resin for the bonding layer are as follows:

[0038] (1) respectively carry out dehydration treatment with phthalic acid series polyester diol, PTMG-1, PTMG-2;

[0039] (2) 1000g dimethylformamide, 0.3g antioxidant, 420g polyether polyol (PTMG-2), 280g polyether polyol (PTMG-1), 260g phthalic acid polyester diol Put it into the reaction kettle and mix evenly, then add organic bismuth catalyst and isocyanate ...

Embodiment 2

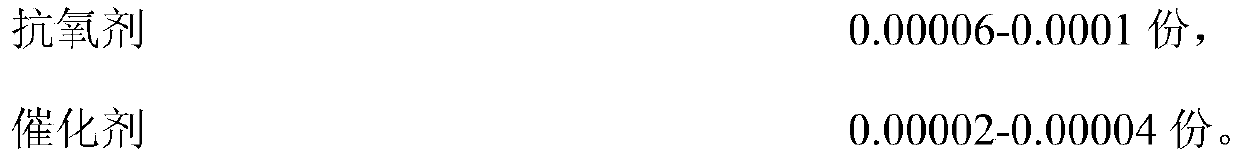

[0042] The bonding layer in the present embodiment uses polyurethane resin, and raw material composition and addition are shown in the following table:

[0043]

[0044]

[0045] In the present embodiment, the preparation steps of the polyurethane resin for the bonding layer are as follows:

[0046] (1) carrying out dehydration treatment with isophthalic acid series polyester glycol, PTMG-1, PTMG-2 respectively;

[0047] (2) 1000g dimethylformamide, 0.3g antioxidant, 420g polyether polyol (PTMG-2), 280g polyether polyol (PTMG-1), 250g isophthalic acid polyester diol Put it into the reaction kettle and mix evenly, then add organic bismuth catalyst and isocyanate accounting for 65% of the total isocyanate weight, and react at 70°C for 50 minutes;

[0048] (3) Add the remaining amount of isocyanate to the above mixture several times to carry out the viscosity-increasing reaction, react at 70°C for 40 minutes in each step, and have a total of 9 hours in the viscosity-increa...

Embodiment 3

[0050] The bonding layer in the present embodiment uses polyurethane resin, and raw material composition and addition are shown in the following table:

[0051] raw material name Weight (unit: g) 4,4′-Diphenylmethane diisocyanate (MDI) 423 Polyether polyol (PTMG-2) 520 Polyether polyol (PTMG-1) 280 Isophthalic acid polyester diol (Amway SP-2250) 280 Antioxidant UHS-301 0.3 Organic Bismuth Catalyst (MB20) 0.1 N,N-Dimethylformamide (DMF) 2800

[0052] In the present embodiment, the preparation steps of the polyurethane resin for the bonding layer are as follows:

[0053] (1) carrying out dehydration treatment with isophthalic acid series polyester glycol, PTMG-1, PTMG-2 respectively;

[0054] (2) 1000g dimethylformamide, 0.3g antioxidant, 520g polyether polyol (PTMG-2), 280g polyether polyol (PTMG-1), 280g isophthalic acid polyester diol Put it into the reaction kettle and mix evenly, then add organic bismuth catalyst and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com