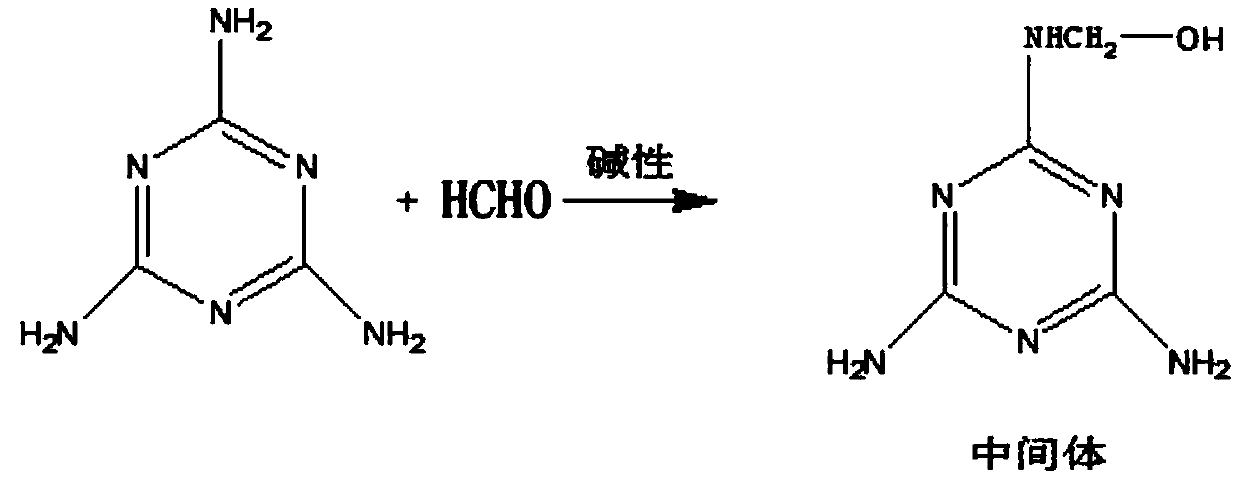

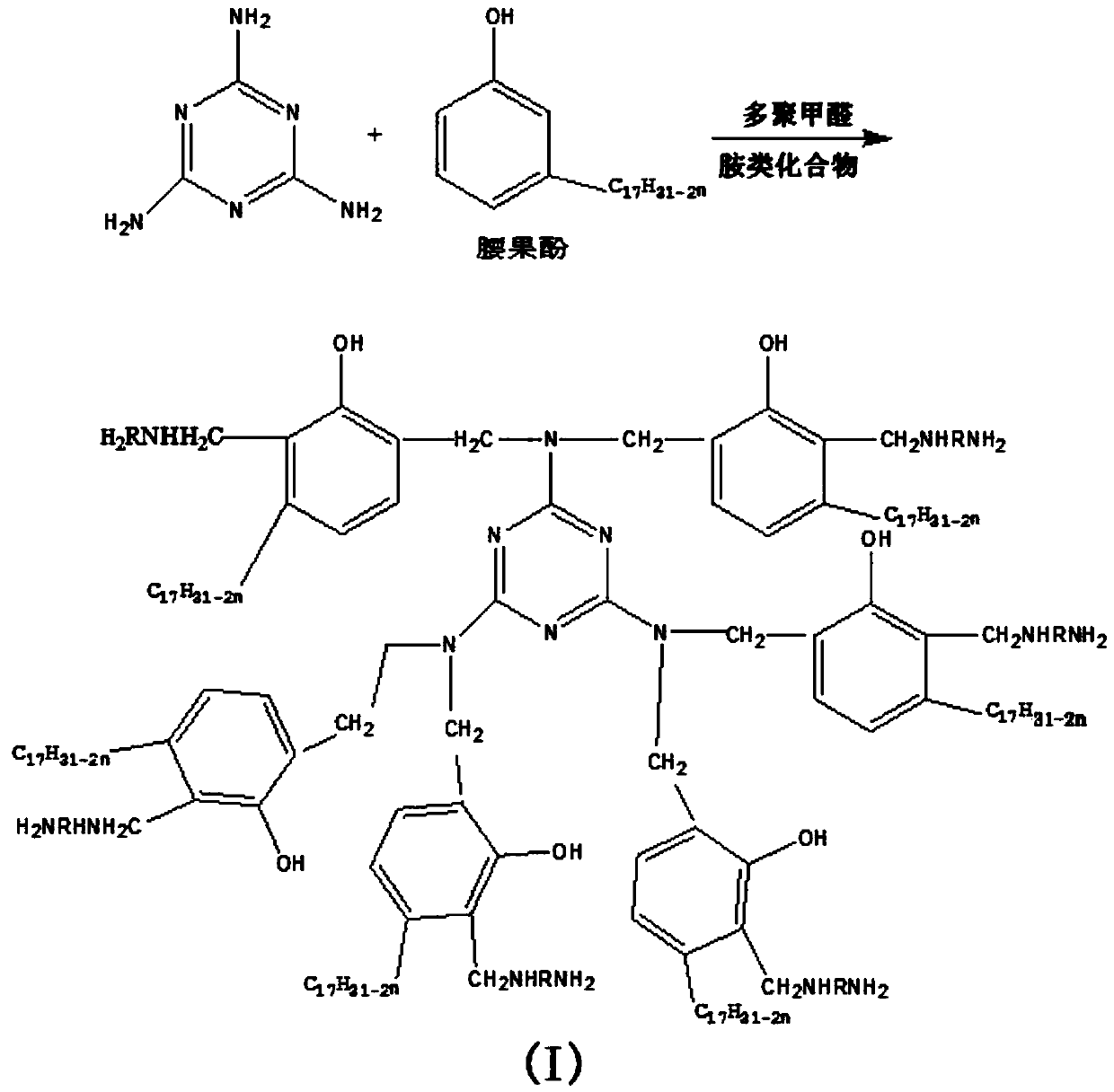

Melamine cardanol modified curing agent preparation method

A technology of melamine and cardanol, used in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of severe heat release, excess, and oily surface on the appearance of the paint film, and achieves high reaction temperature and reaction time. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of melamine cardanol modified curing agent, comprising the following steps:

[0033] 1) Add 150 g of cardanol, 30 g of paraformaldehyde and 6 g of melamine into a four-necked flask and mix evenly to obtain a mixture A; add ethylenediamine (30 g) dropwise to the mixture A, exothermic during the addition of ethylenediamine Obviously, control the mixing temperature of the mixture A and the dropwise added ethylenediamine to react at 45-50° C. After the dropwise addition of ethylenediamine is completed (the dropwise addition time is about 1 hour), keep warm and continue to react for 2 hours;

[0034] 2) Step 1) After the heat preservation reaction is completed, add the remaining cardanol 150g and the remaining paraformaldehyde 30g, control the temperature at 45-50°C and add ethylenediamine (30g) dropwise, after the addition of ethylenediamine is completed (dropping time is about 1 hour), insulation continues to react for 1 hour;

[0035] 3) Step 2) Afte...

Embodiment 2

[0040] A preparation method of melamine cardanol modified curing agent, comprising the following steps:

[0041] 1) Add 151 g of cardanol, 31 g of paraformaldehyde and 6 g of melamine into a four-necked flask and mix uniformly to obtain a mixture A; add ethylenediamine (20 g) dropwise to the mixture A, exothermic during the addition of ethylenediamine Obviously, control the mixing temperature of the mixture A and the ethylenediamine added dropwise to react at 40-45° C. After the dropwise addition of ethylenediamine is completed (the dropping time is about 1 hour), keep warm and continue to react for 2 hours;

[0042] 2) Step 1) After the heat preservation reaction, add the remaining cardanol 148g and the remaining paraformaldehyde 30g, control the temperature at 40-45°C and add ethylenediamine (20g) dropwise, after the addition of ethylenediamine is completed (dropping time is about 1 hour), insulation continues to react for 2 hours;

[0043] 3) Step 2) After the heat preserv...

Embodiment 3

[0045] A preparation method of melamine cardanol modified curing agent, comprising the following steps:

[0046] 1) Add 152 g of cardanol, 35 g of paraformaldehyde and 12 g of melamine into a four-necked flask and mix uniformly to obtain a mixture A; add ethylenediamine (20 g) dropwise to the mixture A, exothermic during the addition of ethylenediamine Obviously, control the mixing temperature of the mixture A and the ethylenediamine added dropwise to react at 40-45° C. After the dropwise addition of ethylenediamine is completed (the dropping time is about 1 hour), keep warm and continue to react for 2 hours;

[0047] 2) Step 1) After the heat preservation reaction is completed, add the remaining cardanol 150g and the remaining paraformaldehyde 35g, control the temperature at 40-45°C and add ethylenediamine (20g) dropwise, after the addition of ethylenediamine is completed (dropping time is about 1 hour), insulation continues to react for 2 hours;

[0048] 3) Step 2) After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com