Preparation method of 5-maleimide chromone compound

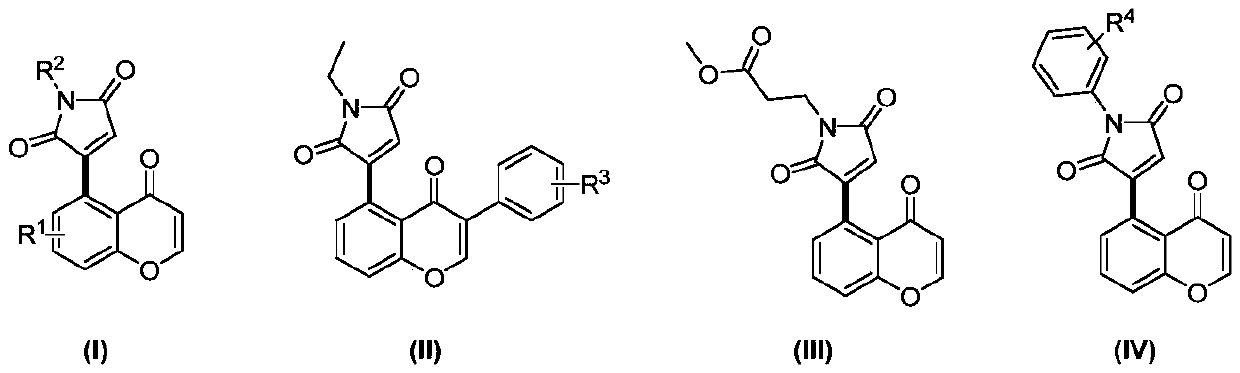

A technology for maleimide chromone and chromone compounds, which is applied in the field of ruthenium-catalyzed preparation of 5-maleimide chromone compounds, which can solve the problems of inability to carry out β hydrogen and elimination, and achieve the reaction time Short, high-yield, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

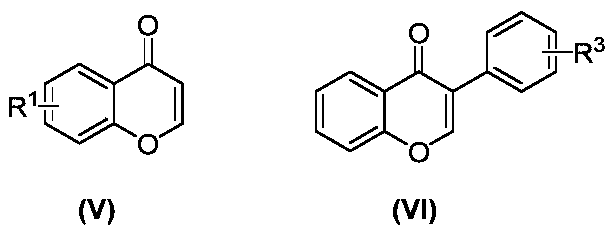

[0029] At room temperature, chromone (0.2mmol), N-ethylmaleimide (0.5mmol), [Ru(p-cymene)Cl 2 ] 2 (5mol%), AgNTf 2 (20mol%), silver acetate (3 equiv.) and DCE (2.0 mL). Raise the temperature to 120°C and stir. TLC tracking detection reaction. After 1 hour, the reaction was stopped. Water and ethyl acetate were added to the reaction system, the organic layer was separated, and the aqueous layer was washed three times with ethyl acetate. Combine all organic layers, dry with anhydrous sodium sulfate, concentrate, and separate by column chromatography (40% ethyl acetate petroleum ether solution), obtain product 49.5mg, productive rate is 92%, reaction process is shown in the following formula:

[0030]

[0031] Carry out nuclear magnetic resonance analysis to the product that present embodiment prepares:

[0032] 1 H NMR (400MHz, CDCl 3 )δ7.83(d, J=6.0Hz, 1H), 7.71–7.67(m, 1H), 7.57(d, J=8.5Hz, 1H), 7.22(d, J=7.3Hz, 1H), 6.42( s, 1H), 6.28 (d, J = 6.0Hz, 1H), 3.63 (q, ...

Embodiment 2

[0034] At room temperature, chromone (0.2mmol), N-ethylmaleimide (0.5mmol), [Ru(p-cymene)Cl 2 ] 2 (5mol%), AgNTf 2 (20mol%), silver acetate (3 equiv.) and chlorobenzene (2.0 mL). Raise the temperature to 120°C and stir. TLC tracking detection reaction. After 3.5 hours, the reaction was stopped. Water and ethyl acetate were added to the reaction system, the organic layer was separated, and the aqueous layer was washed three times with ethyl acetate. Combine all organic layers, dry with anhydrous sodium sulfate, concentrate, and separate by column chromatography (40% ethyl acetate petroleum ether solution), obtain product 45.2mg, yield rate is 84%, and reaction process is shown in the following formula:

[0035]

[0036] Carry out nuclear magnetic resonance analysis to the product that present embodiment prepares:

[0037] 1 H NMR (400MHz, CDCl 3 )δ7.83(d, J=6.0Hz, 1H), 7.71–7.67(m, 1H), 7.57(d, J=8.5Hz, 1H), 7.22(d, J=7.3Hz, 1H), 6.42( s, 1H), 6.28 (d, J = 6.0Hz, 1H...

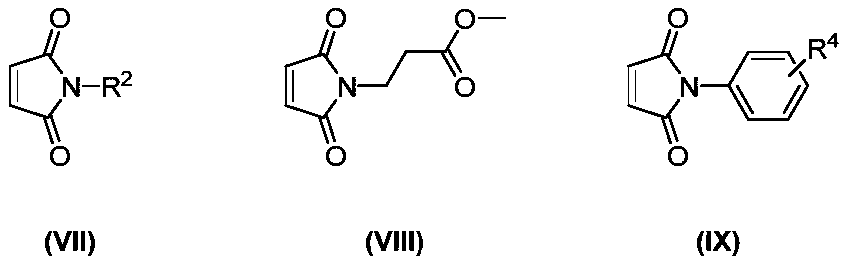

Embodiment 3

[0039] At room temperature, chromone (0.2mmol), N-ethylmaleimide (0.5mmol), [Ru(p-cymene)Cl 2 ] 2 (5mol%), AgNTf 2 (20mol%), silver acetate (3 equiv.) and ethyl acetate (2.0 mL). Raise the temperature to 120°C and stir. TLC tracking detection reaction. After 3.5 hours, the reaction was stopped. Water and ethyl acetate were added to the reaction system, the organic layer was separated, and the aqueous layer was washed three times with ethyl acetate. Combine all organic layers, dry with anhydrous sodium sulfate, concentrate, and separate by column chromatography (40% ethyl acetate petroleum ether solution), obtain product 30.7mg, productive rate is 57%, and reaction process is shown in the following formula:

[0040]

[0041] Carry out nuclear magnetic resonance analysis to the product that present embodiment prepares:

[0042] 1 H NMR (400MHz, CDCl 3 )δ7.83(d, J=6.0Hz, 1H), 7.71–7.67(m, 1H), 7.57(d, J=8.5Hz, 1H), 7.22(d, J=7.3Hz, 1H), 6.42( s, 1H), 6.28 (d, J = 6.0H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com