Method for firing photoluminescence fluorescence glaze ceramic through roller kiln

A roller kiln and photo-induced technology, which is applied in chemical instruments and methods, luminescent materials, applications, etc., can solve the problems of glazed architectural ceramics that have not yet appeared photo-induced red fluorescence, and achieve low cost, consistent shrinkage, and relative good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

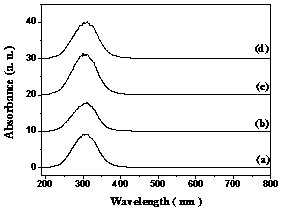

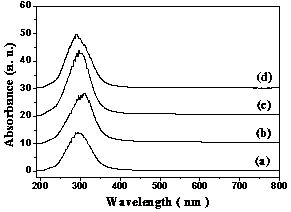

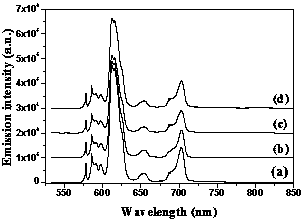

[0019] (1) Ingredients according to mass percentage: 36.25% dolomite, 27.18% quartz, 5.58% europium oxide, 3.81% yttrium oxide, 27.18% aluminum hydroxide, add water, make the mass ratio of material to water 100:80, in planetary In a ball mill, after ball milling at a speed of 400 rpm for 1 hour, the slurry was dried at 110°C, and then calcined at 1175°C for 15 minutes to obtain a photoluminescent fluorescent powder; the prepared photoluminescent fluorescent The powder is mixed with other raw materials according to mass percentage: 7.46% kaolin, 11.94% talc, 5.97% pyrophyllite, 59.70% medium-temperature frit, 14.93% photoluminescence fluorescent powder, among which, the chemical composition of the medium-temperature frit is 1.77%Na 2 O, 2.00%MgO, 5.97%Al 2 o 3 , 61.59%SiO2 2 , 5.61%K 2 O, 8.63%CaO, 11.7%ZnO, 2.73%BaO, add water, make the mass ratio of material to water 100:80, after ball milling in a planetary ball mill at a speed of 400 rpm for 1 hour, the fluorescent glaze...

Embodiment 2

[0024] (1) Ingredients according to mass percentage: 36.25% dolomite, 27.18% quartz, 5.58% europium oxide, 3.81% yttrium oxide, 27.18% aluminum hydroxide, add water, make the mass ratio of material to water 100:80, in planetary In a ball mill, after ball milling at a speed of 400 rpm for 1 hour, the slurry was dried at 110°C, and then calcined at 1175°C for 15 minutes to obtain a photoluminescent fluorescent powder; the prepared photoluminescent fluorescent The powder is mixed with other raw materials according to mass percentage: 7.69% kaolin, 12.31% talc, 3.07% pyrophyllite, 61.54% medium-temperature frit, 15.39% photoluminescent fluorescent powder, among which, the chemical composition of the medium-temperature frit is 1.77%Na 2 O, 2.00%MgO, 5.97%Al 2 o 3 , 61.59%SiO2 2 , 5.61%K 2 O, 8.63%CaO, 11.7%ZnO, 2.73%BaO, add water, make the mass ratio of material to water 100:80, after ball milling in a planetary ball mill at a speed of 400 rpm for 1 hour, the fluorescent glaze ...

Embodiment 3

[0029] (1) Ingredients according to mass percentage: 36.25% dolomite, 27.18% quartz, 5.58% europium oxide, 3.81% yttrium oxide, 27.18% aluminum hydroxide, add water, make the mass ratio of material to water 100:80, in planetary In a ball mill, after ball milling at a speed of 400 rpm for 1 hour, the slurry was dried at 110°C, and then calcined at 1175°C for 15 minutes to obtain a photoluminescent fluorescent powder; the prepared photoluminescent fluorescent The powder is mixed with other raw materials according to mass percentage: 7.25% kaolin, 11.59% talc, 8.7% pyrophyllite, 57.97% medium-temperature frit, 14.49% photoluminescent fluorescent powder, and the chemical composition of the medium-temperature frit is 1.77%Na 2 O, 2.00%MgO, 5.97%Al 2 o 3 , 61.59%SiO2 2 , 5.61%K 2 O, 8.63%CaO, 11.7%ZnO, 2.73%BaO, add water, make the mass ratio of material to water 100:80, after ball milling in a planetary ball mill at a speed of 400 rpm for 1 hour, the fluorescent glaze is produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com