Porous biochar based on typha orientalis derivation and production method and application of porous biochar based on typha orientalis derivation

A technology of biochar and cattail, applied in the field of porous biochar, can solve the problems of low efficiency of levofloxacin and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Wash, dry, crush, and pass through a 200-mesh sieve to obtain cattail powder, then place the cattail powder in a tube furnace, and under oxygen-isolated conditions, raise the temperature to 450°C at a rate of 10°C / min, keep it for 2 hours, and pass through 2mol / Wash with L hydrochloric acid and pure water to neutrality, and dry to obtain biochar.

[0029] Fully grind the biochar with twice the mass ratio of potassium carbonate for 20 minutes, place it in an anaerobic tube furnace, raise the temperature to 900°C at a rate of 10°C / min, keep it for 2 hours, and pass through 2mol / L hydrochloric acid and pure Wash with water until neutral, and dry to obtain porous biochar, referred to as MPCS-900.

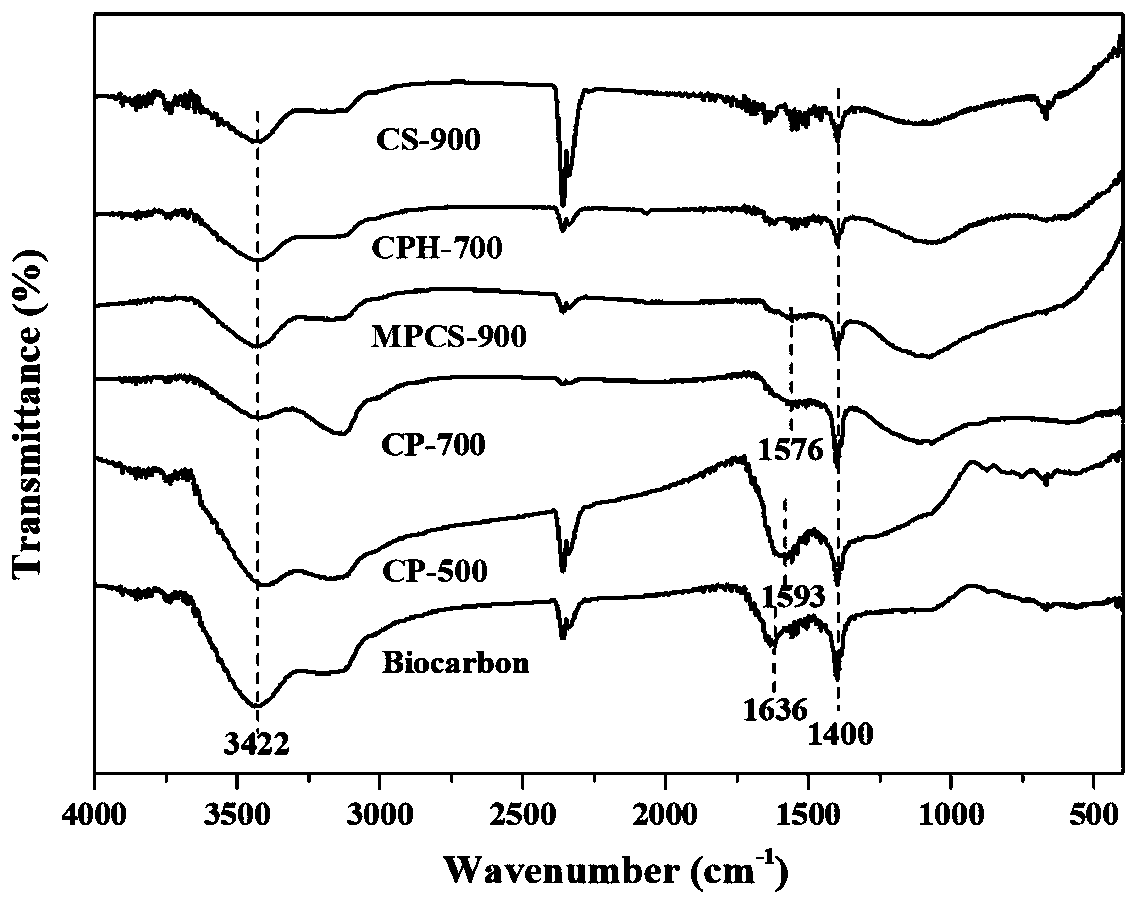

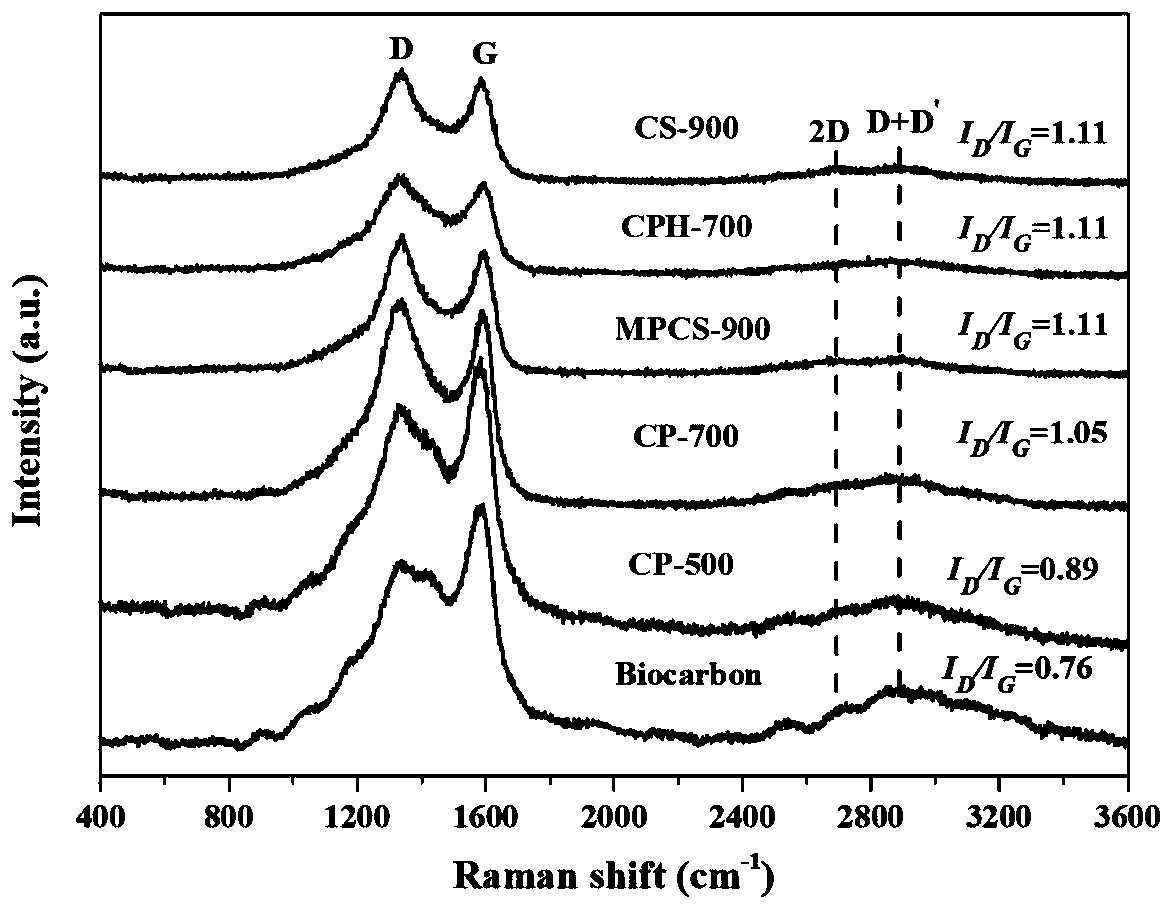

[0030] In order to study MPCS-900 further, the inventor scanned it with an electron microscope, and the results are as follows figure 1 As shown, the scanning electron microscope image shows that MPCS-900 is an irregular, stacked lamellar structure. According to the transmissio...

Embodiment 2

[0038] The influence of embodiment 2 calcining temperature on material adsorption performance

[0039] Weigh 10mg of the porous biochar MPCS-900 prepared in Example 1 and the CP-500 and CP-700 prepared in Comparative Example 1 respectively in three 250mL conical flasks with stoppers, and add the calculated Pure water, ultrasonic 5min until the solution is uniform, then add levofloxacin of known concentration to make the total volume 100mL, wherein the initial concentration of levofloxacin is 30mg / L, adjust pH=7.0±0.1, put the above device in a constant temperature oscillator ( 150rpm, 25 DEG C), get a point at regular intervals, then pass through a 22um filter head, detect the absorbance of its sample with a UV-Vis spectrophotometer, calculate the levofloxacin concentration according to the absorbance, draw the time-removal rate adsorption curve according to the levofloxacin concentration ( see Figure 6 , removal rate%=(C 0 -C e )×100% / C 0 ), among them, the adsorption ra...

Embodiment 3

[0040] Embodiment 3 different activating reagents influence on the adsorption performance of adsorbent material

[0041] Weigh 10 mg of the porous biochar MPCS-900 prepared in Example 1, CS-900 and CPH-700 prepared in Comparative Example 2 into 250 mL of three conical flasks with stoppers, add the calculated pure water, and ultrasonicate for 5 minutes Until the solution is uniform, then add levofloxacin of known concentration to make the total volume 100mL, and make the initial concentration of levofloxacin in it be 30mg / L, adjust pH=7.0±0.1, put the above-mentioned device in a constant temperature oscillator (150rpm, 25 ℃), take a point every certain interval, then pass through a 22um filter head, and use a UV-visible spectrophotometer to detect the absorbance of the sample. The blank experiment (without adsorbent) is also the same operation, and its time-removal rate adsorption curve see Figure 7 , it can be seen that the adsorption properties of porous biochars prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hole width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com