Steel wire twisting prevention device

A technology of wire winding and anti-winding, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, and can solve the problems of easy winding of steel wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

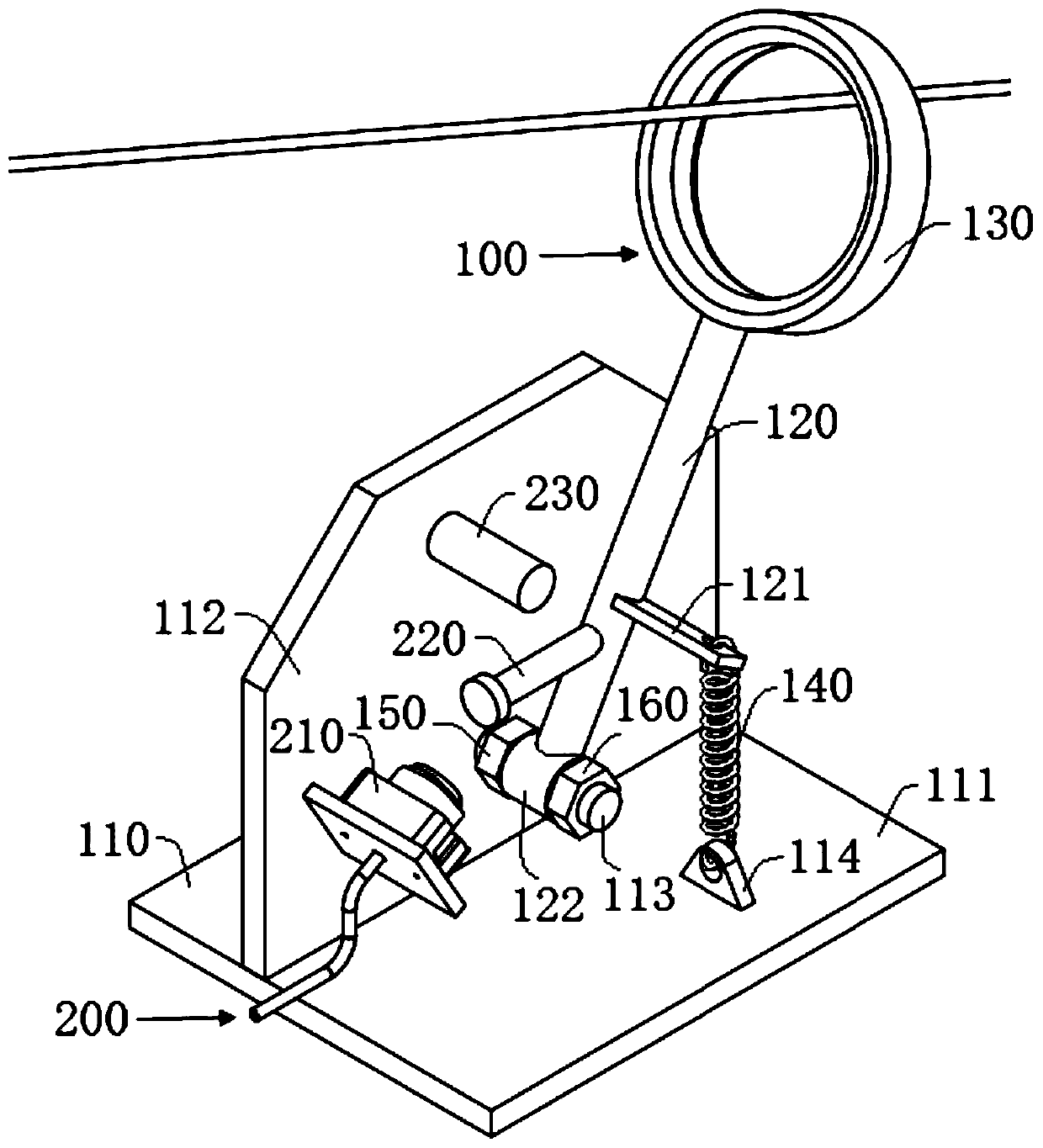

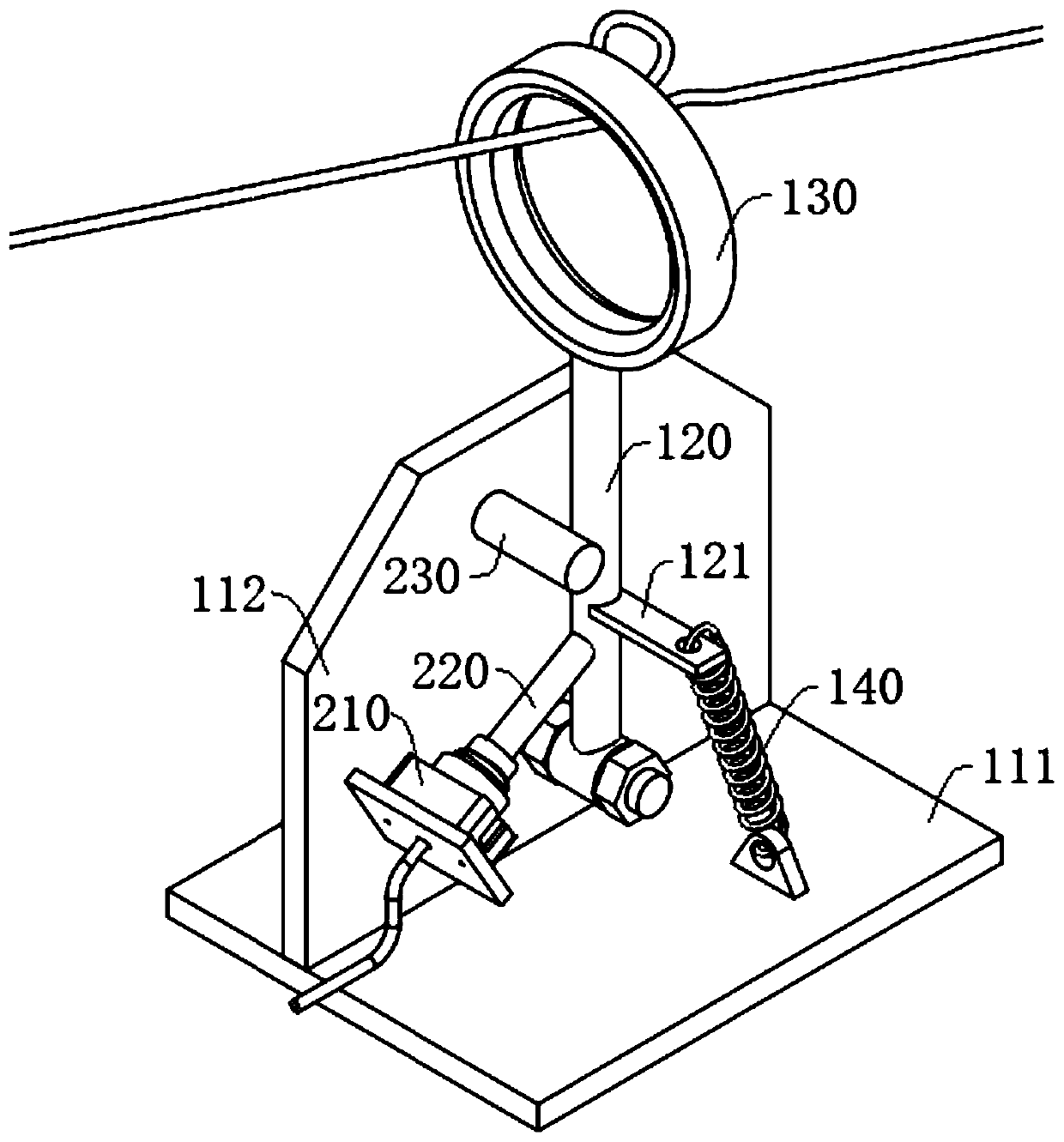

[0037] Such as figure 1 and figure 2 As shown, an anti-steel wire winding device of this embodiment includes an anti-steel winding assembly 100 and an emergency stop assembly 200, which cooperate together to complete the anti-steel winding work. The anti-steel winding device of this embodiment is mainly used in factories to curl steel wires into bundles , Use a wire winding machine to wind up the wire during the wire crimping process. An anti-steel wire winding device in this embodiment, during the steel wire winding process of the steel wire winding machine, the anti-winding component 100 is used to prevent the steel wire from being entangled during the winding process, and an emergency stop component is added while the steel wire is performing anti-winding 200 controls the steel wire winding machine, so that the steel wire can be wound safely and effectively, prevents the wire winding machine from being damaged due to the winding of the steel wire during the winding proces...

Embodiment 2

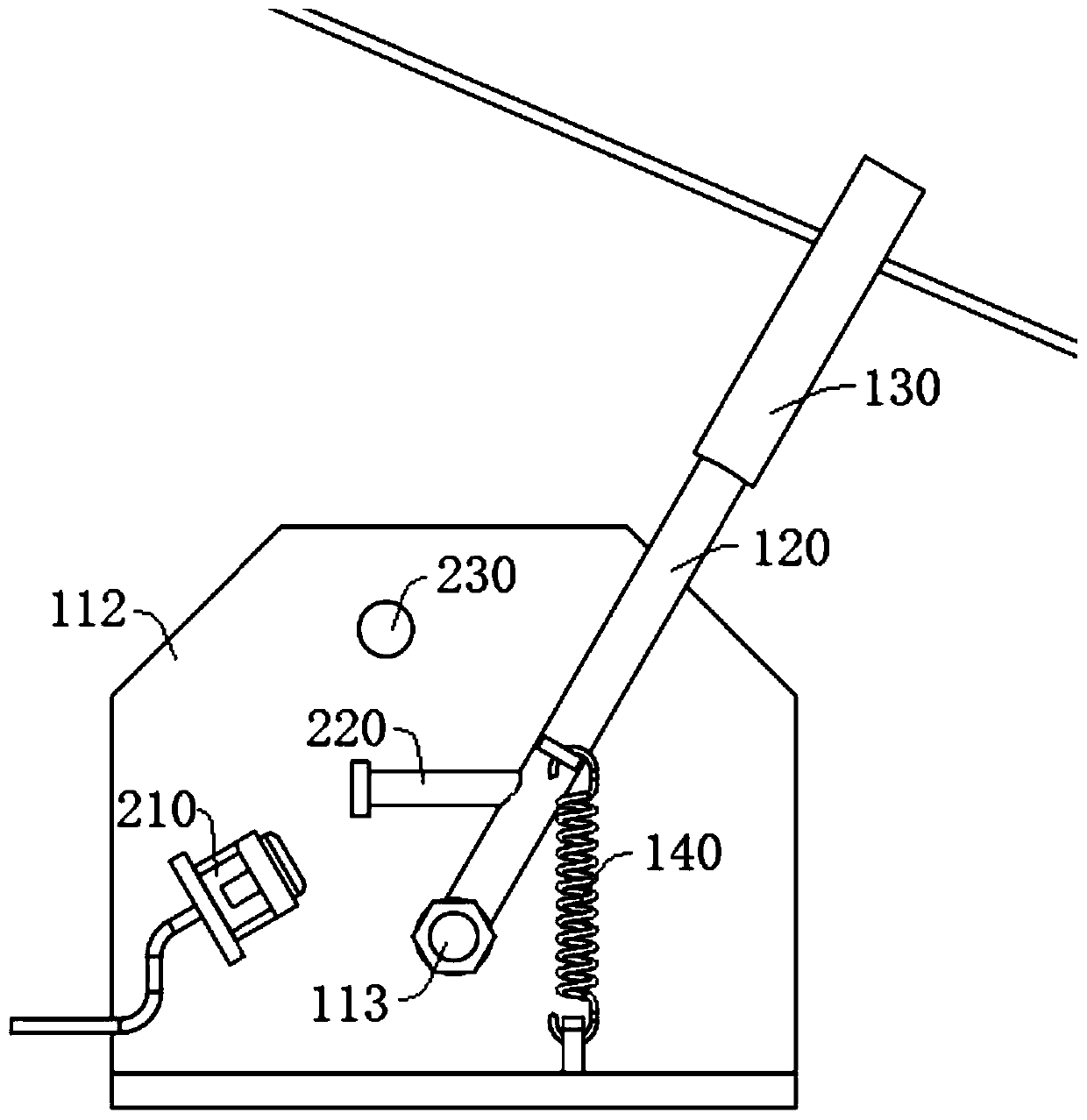

[0048] Such as image 3 and Figure 4 As shown, the anti-steel wire entanglement device of this embodiment has the same structure as that of embodiment 1, except that the working process of the anti-steel wire tangle device is described when the steel wire is entangled.

[0049] When the steel wire is twisted, if there is only a small crimp, the steel wire will be corrected when it passes through the limiting ring 130 . When the steel wire winding part cannot pass through the limit ring 130, the wound steel wire drives the limit ring 130 to move, the connecting rod 120 plays the role of transmission, the annular sleeve 122 rotates around the connecting rod 113, the fixed piece 121 pulls the elastic member 140 to move, The pressing part 220 is close to the emergency stop switch 210, and press the emergency stop switch 210, the limit rod 230 blocks the connecting rod 120 so that the pressing part 220 cannot continue to move, the emergency stop switch 210 is connected with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com