Bacterium-enzyme synergistic fermentation method containing camellia seed meal

A camellia seed and starter technology, applied in animal feed, animal husbandry, applications, etc., can solve problems such as interference with nutrient absorption, reduced protein digestibility, strong toxicity, etc., to reduce bitterness, bitterness, and astringency. The effect of moderate acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of indicator bacteria liquid: Escherichia coli, Salmonella and Staphylococcus aureus were inoculated in LB liquid medium and cultured at 37°C for 24 hours.

[0032] Adopt the Oxford cup method: take a plate with a diameter of about 90 mm, pour 15-20 mL of heated and melted nutrient agar medium into the plate, spread it evenly in the plate, place it on a horizontal platform to solidify, and use it as the bottom layer. Take another semi-solid nutrient agar medium (agar content is 1%), heat and melt in an appropriate amount, let it cool to 48-50°C, add 0.1-0.2mL of indicator bacteria suspension per 50-100mL of medium, and put it on each plate Add 5mL to each of them to make it spread evenly on the bottom layer as a bacterial layer. Evenly place 4-5 Oxford cups on each plate at equidistant distances, drop 200 μL of lactic acid bacteria supernatant into the Oxford cups in each double-layer plate, and measure the inhibition zone after incubation at 37°C for 10-13 ...

Embodiment 1

[0037] Embodiment 1: the screening of bacterial strain

[0038] The bacterial strain of the present invention adopts the plate dilution separation method to isolate and screen the Gram-positive bacterial strain with good antibacterial effect from the camellia seed meal sample. The isolation screening method is as follows:

[0039] 1. Dilution of mixed strains: Weigh a sample of camellia seed meal, put 1g of camellia seed meal into MRS medium at 37°C for 24 hours, and perform gradient dilution of the bacterial solution;

[0040] 2. Prepare MRS medium: peptone 10.0g, beef extract 8.0g, yeast powder 4.0g, glucose 20.0g, dipotassium hydrogen phosphate 2.0g, triammonium citrate 2.0g, sodium acetate 5.0g, magnesium sulfate heptahydrate 0.58g , manganese sulfate tetrahydrate 0.25g, Tween 801mL, distilled water 1L, sterilized at 115°C for 20 minutes;

[0041]3. Primary screening of bacterial strains: Take 100 microliters of the bacterial solution after gradient dilution in step 1 an...

Embodiment 2

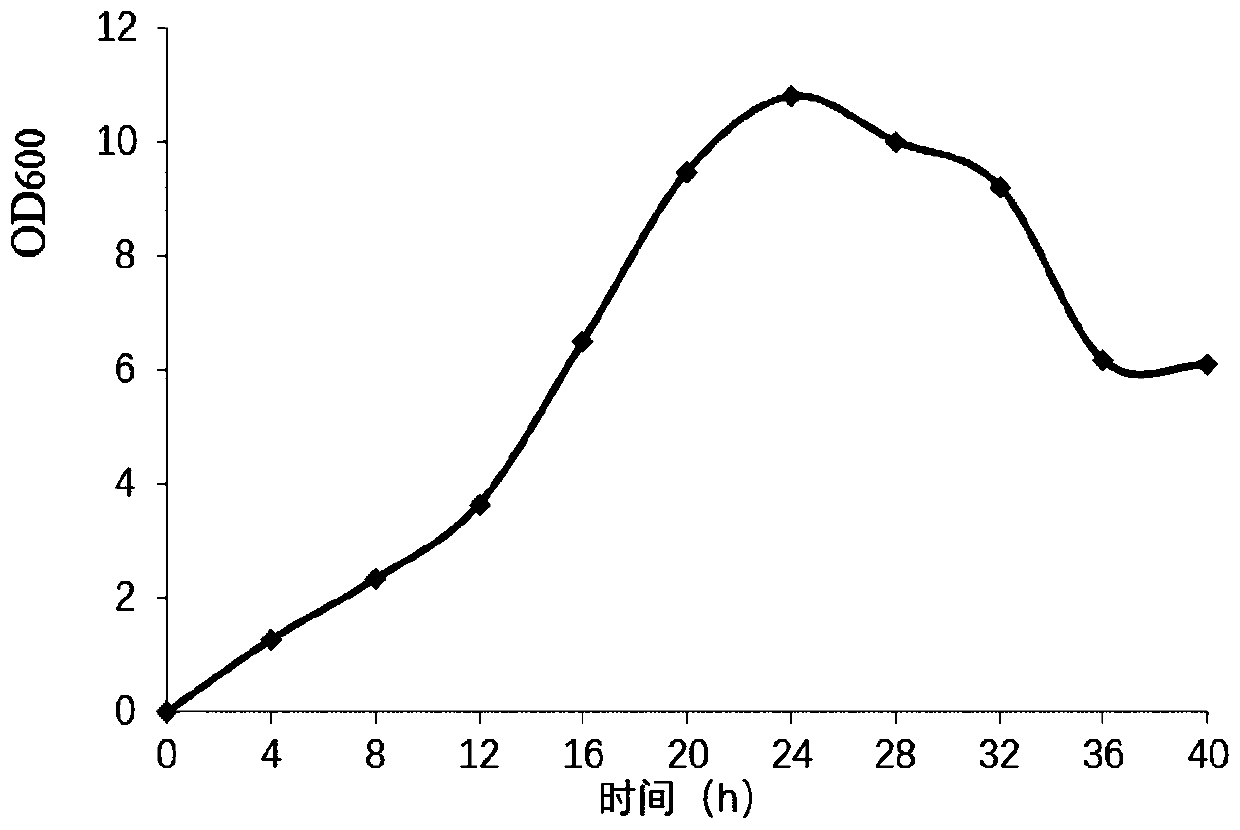

[0048] Example 2: Process determination and antibacterial effect of Lactobacillus plantarum fermented camellia seed meal

[0049] In order to explore the optimal nutrient composition ratio and fermentation process of the antibacterial activity after bacterial enzyme synergistic fermentation, based on the MRS medium, an orthogonal experiment was designed to study the effect of the following four components on the fermented camellia seed meal: water, cellulose Enzyme, alkaline protease, bacterial liquid DY6. See Table 2 for factor levels.

[0050] Table 2 Screening factors and levels of bacterial enzyme synergistic fermentation components

[0051]

[0052] Table 3 Orthogonal experiment results

[0053]

[0054] Through the analysis of orthogonal experiments (seeing table 3), the optimal process conditions for bacterial enzyme synergistic fermentation of camellia seed meal are: moisture is 50%, cellulase is 300U / g substrate, alkaline protease is 800U / g substrate, DY6 ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com