Made in composition, gloves and gloves for immersion molding

A technology of dip molding and composition, which is applied in the field of dip molding composition, glove manufacturing and gloves, which can solve the problems of unfulfilled performance and achieve the effect of high fatigue durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0319]Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples. Unless otherwise specified, "%" means "% by weight", and "part" means "parts by weight".

[0320] In addition, in the following description, "parts by weight" basically means the number of parts by weight with respect to 100 parts by weight of an elastomer.

[0321] The parts by weight of each additive are values based on the solid content, and the parts by weight of the epoxy crosslinking agent are values based on the total weight of the crosslinking agent.

[0322] In addition, the pot life was determined based on the time from when the epoxy crosslinking agent was added when preparing the dip molding composition to when the dip molding composition was attached to the glove molding mold. In addition, the types of XNBR and epoxy crosslinking agent used in the composition for dip molding are described in each table.

[0...

experiment example 1

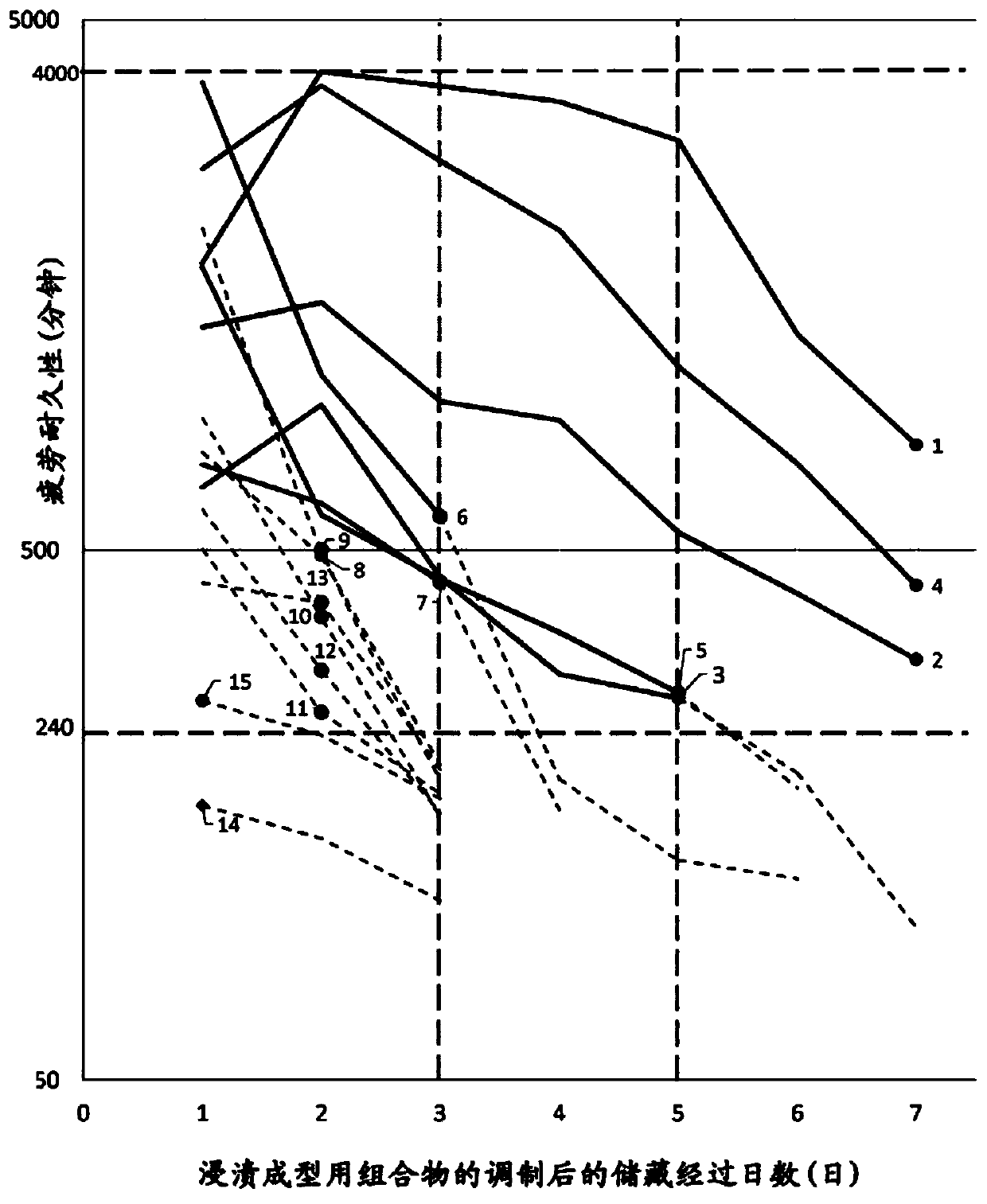

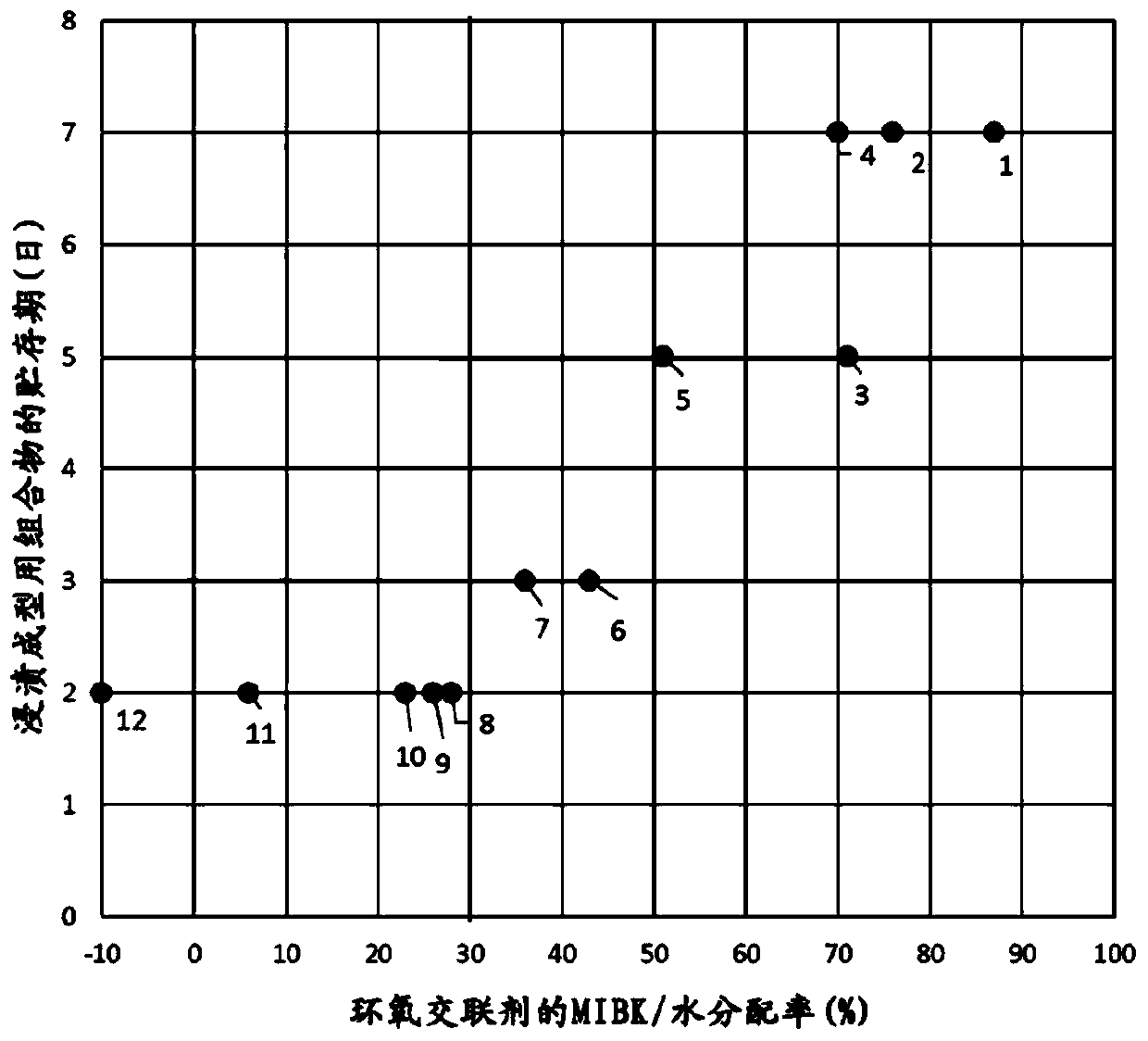

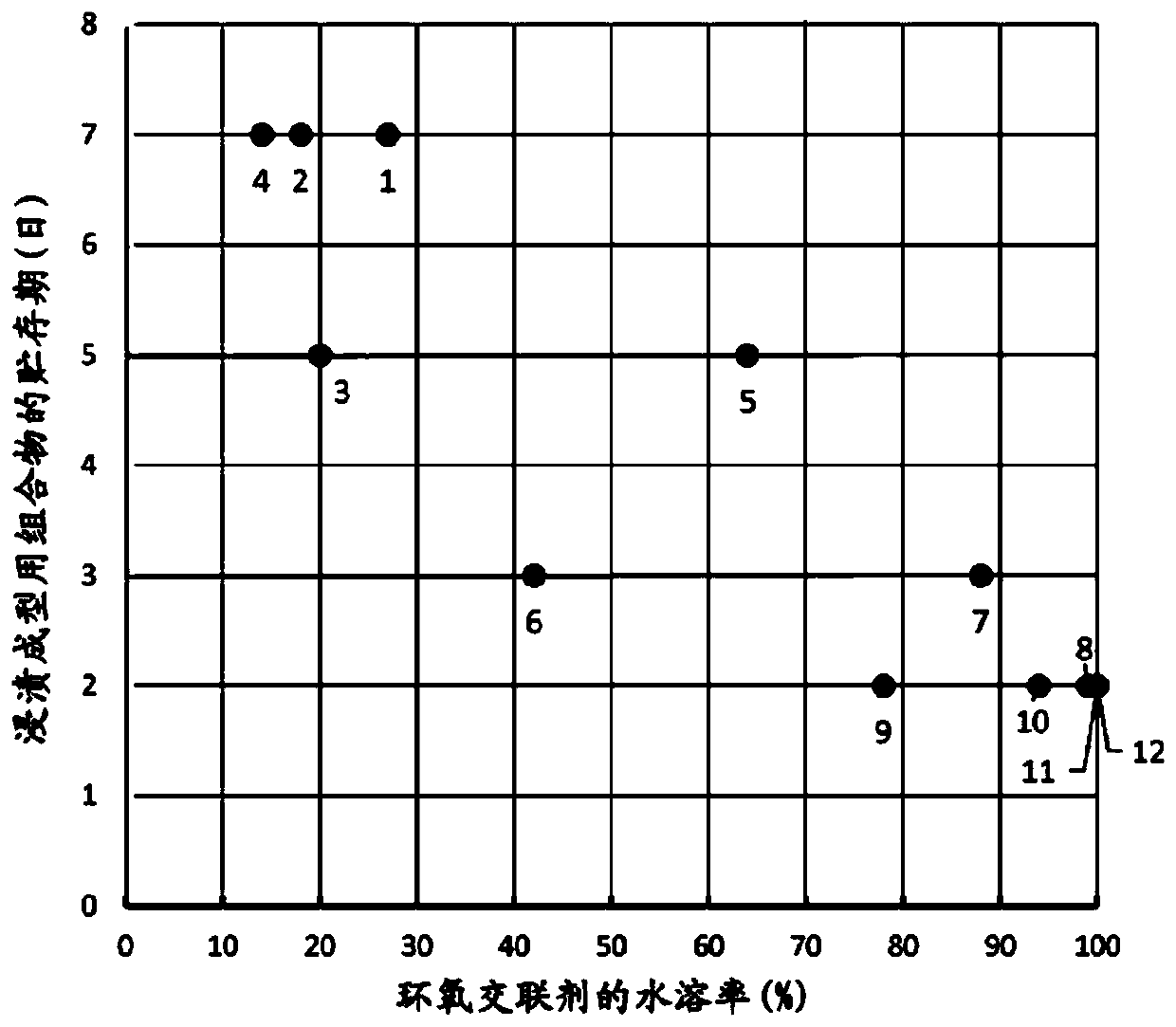

[0399] This experimental example is an experimental example to verify the correlation between the water solubility or MIBK / water partition ratio of each epoxy crosslinking agent and the pot life of the composition for dip molding.

[0400] In addition, regarding the pot life of the composition for dip molding, it calculated|required according to the following procedure. The unit of storage period is "day". Using each epoxy crosslinking agent, the dip molding composition was prepared and stored while being stirred, and a cured film was produced every day. With regard to the elapsed days of storage of the composition for dip molding, the measurement was performed until the day (the second day after the final passing day) was lower than 240 minutes which is the passing line of the fatigue durability of the cured film. The number of days of storage elapsed until the final pass date was defined as the storage period. In this experimental example, the experiment was performed up t...

experiment example 2

[0415] In this experimental example, for the epoxy crosslinking agent whose storage period is less than 3 days in Experimental Example 1, whether the storage period of 3 days can be obtained if the addition amount is increased to 0.5 parts by weight higher than the addition amount of Experimental Example 1 undergone an experiment.

[0416] As measurement objects, epoxy crosslinking agent H with a storage period of 2 days in Experimental Example 1, epoxy crosslinking agent G with a storage period of 3 days in Experimental Example 1, and trivalent epoxy crosslinking agent I were used. ~L, epoxy crosslinking agent M with relatively high MIBK / water partition ratio among divalent epoxy crosslinking agents.

[0417] In addition, the experimental conditions were the same as in Experimental Example 1 except for the amount of the epoxy crosslinking agent. Table 4 below shows the experimental results.

[0418] [Table 4]

[0419]

[0420] As shown in Table 4, it can be seen that wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com