A high-strength quenched and tempered steel plate for marine engineering and its production method

A technology of marine engineering and production method, which is applied in the field of metallurgy, can solve the problems of restricting the development of special equipment manufacturing industry for marine engineering, high price, long import cycle, etc., and achieve the effects of improving competitiveness, good matching of strength and toughness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

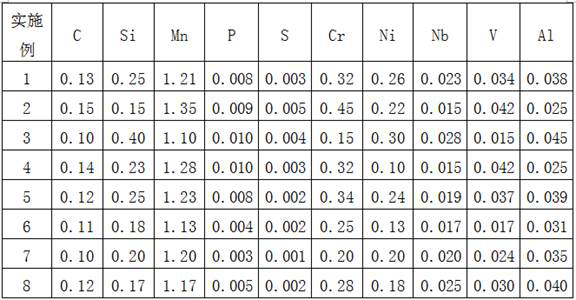

[0030] The thickness of the high-strength quenched and tempered steel plate for marine engineering in this example is 50 mm, and its chemical composition and mass percentage are shown in Table 1.

[0031] The production method of the high-strength quenched and tempered steel plate for offshore engineering in this embodiment includes converter steelmaking, LF refining, VD vacuum treatment, continuous casting, billet heating, rolling, and quenched and tempered heat treatment processes. The specific process steps are as follows:

[0032] (1) LF refining process: The molten steel that has been initially smelted in the converter is sent to the LF refining furnace for refining. During the LF refining process, argon is blown and stirred well throughout the process. The total refining time is 35 minutes, and the white slag retention time is 24 minutes. The final slag alkalinity of LF refining is 5;

[0033] (2) VD vacuum treatment process: After the LF furnace is refined, the molten s...

Embodiment 2

[0040] The thickness of the high-strength quenched and tempered steel plate for marine engineering in this example is 20 mm, and its chemical composition and mass percentage are shown in Table 1.

[0041] The production method of the high-strength quenched and tempered steel plate for offshore engineering in this embodiment includes converter steelmaking, LF refining, VD vacuum treatment, continuous casting, billet heating, rolling, and quenched and tempered heat treatment processes. The specific process steps are as follows:

[0042] (1) LF refining process: The molten steel initially smelted in the converter is sent to the LF refining furnace for refining. During the LF refining process, argon is blown and stirred well throughout the process. The total refining time is 30 minutes, and the white slag retention time is 21 minutes. The final slag alkalinity of LF refining is 4;

[0043] (2) VD vacuum treatment process: After the LF furnace is refined, the molten steel is sent t...

Embodiment 3

[0050] The thickness of the high-strength quenched and tempered steel plate for marine engineering in this example is 30 mm, and its chemical composition and mass percentage are shown in Table 1.

[0051] The production method of the high-strength quenched and tempered steel plate for offshore engineering in this embodiment includes converter steelmaking, LF refining, VD vacuum treatment, continuous casting, billet heating, rolling, and quenched and tempered heat treatment processes. The specific process steps are as follows:

[0052] (1) LF refining process: The molten steel that has been initially smelted in the converter is sent to the LF refining furnace for refining. During the LF refining process, argon is blown and stirred well throughout the process. The total refining time is 36 minutes, and the white slag retention time is 20 minutes. The final slag alkalinity of LF refining is 6;

[0053] (2) VD vacuum treatment process: After the LF furnace is refined, the molten s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com