Multi-spray head 3D printing method

A 3D printing, multi-nozzle technology, applied in the field of 3D printing, can solve the problems of 3D model shape damage, affecting the printing of the first nozzle, affecting the printing quality, etc., to achieve the effect of keeping clean, good cleaning effect, and balanced printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

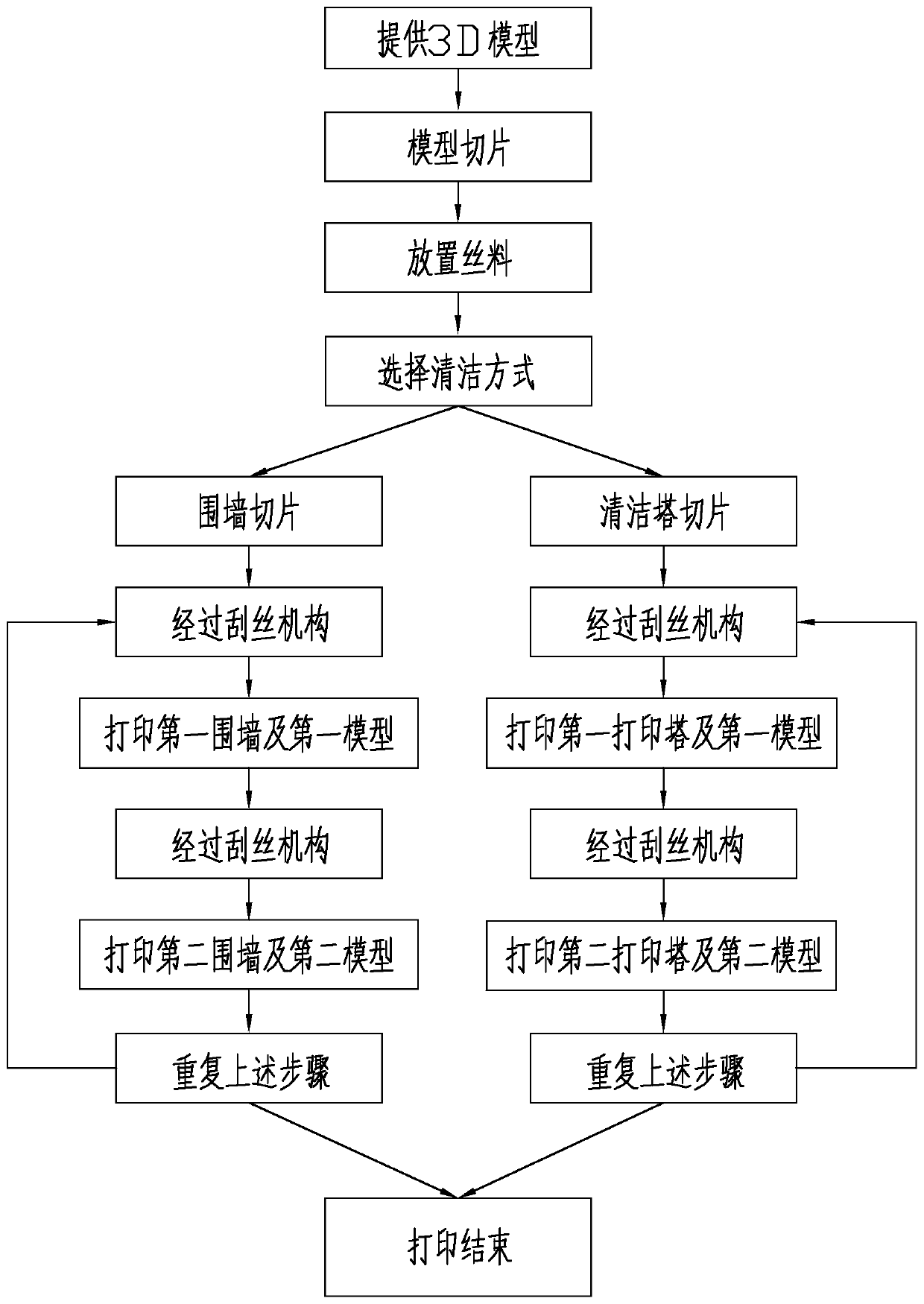

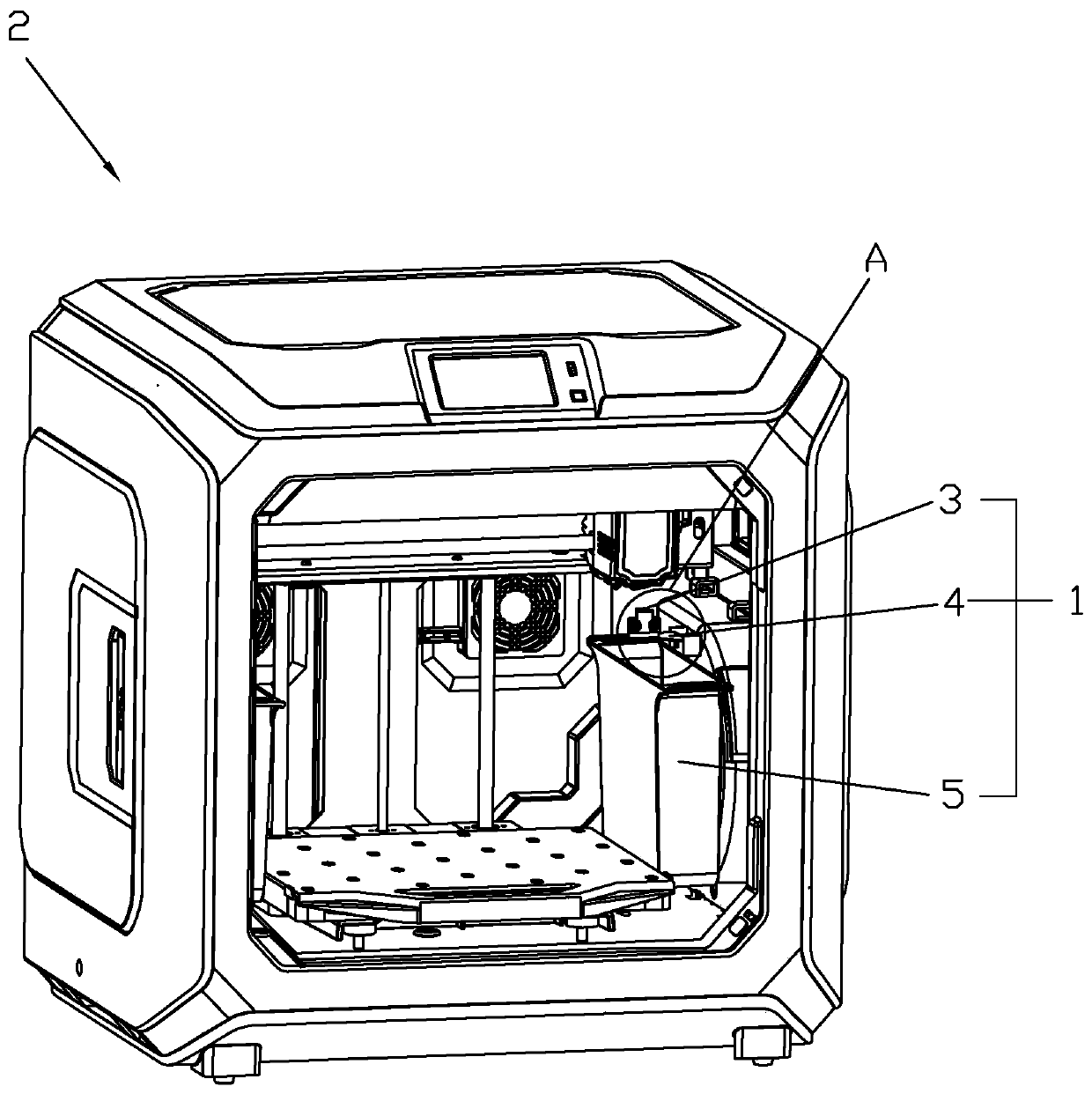

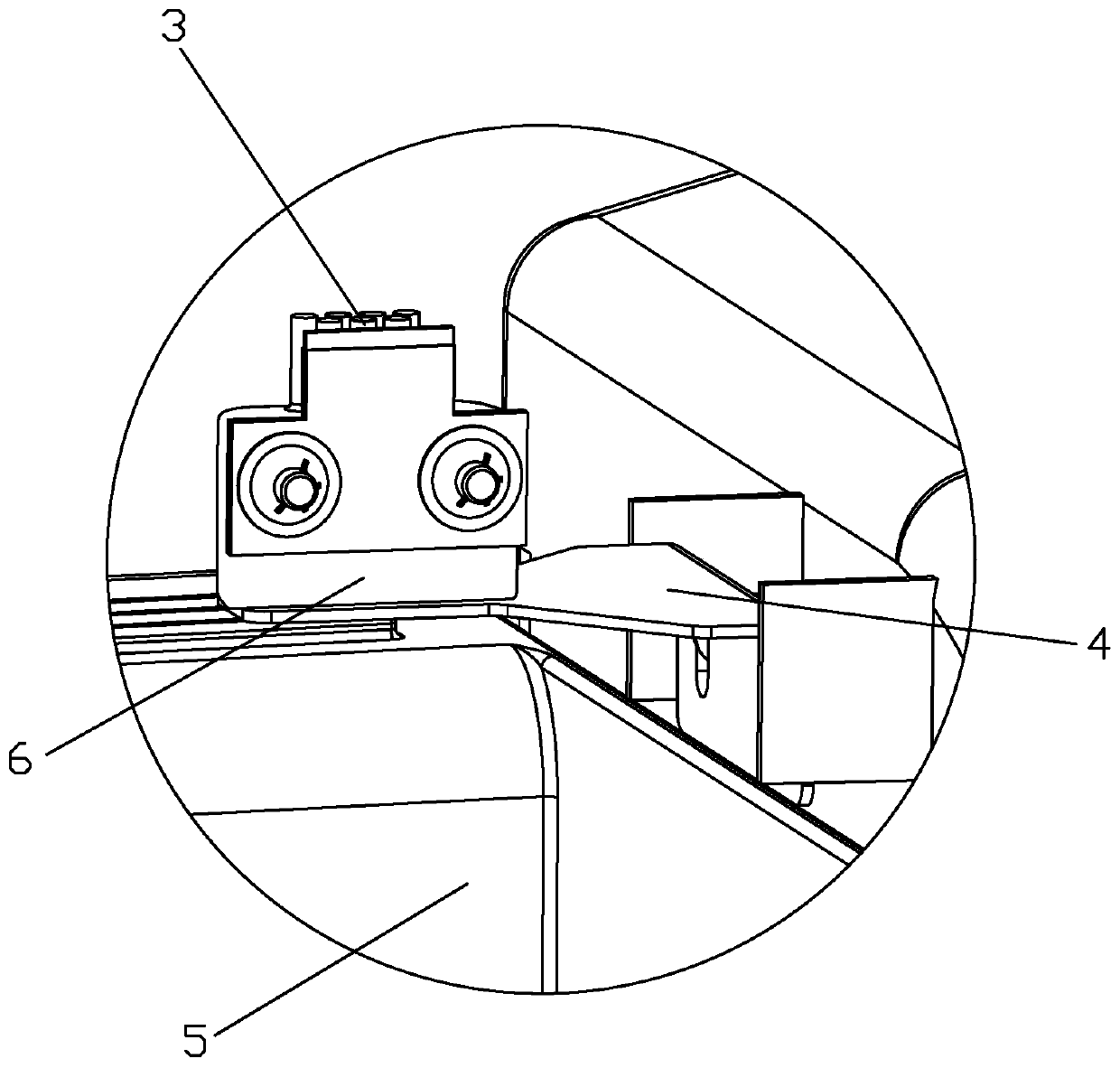

[0036] Such as Figure 1 to Figure 3 A kind of multi-nozzle 3D printing method shown, comprises the steps:

[0037] (1) Provide a 3D model: the 3D model includes a first area and a second area, the multi-nozzle includes a first nozzle and a second nozzle, the first nozzle prints the first area, and the second nozzle prints the second area;

[0038] (2) Model slicing: import the 3D model file into the slicing software (FlashPrint), input the printing parameters, and the slicing software slices the 3D model file in layers according to the printing parameters;

[0039] (3) Place the silk material: place the silk material in the first nozzle and the second nozzle, wherein the silk materials in the two nozzles are different types or different colors of the same type;

[0040] (4) Choose the cleaning method: choose to print the fence or cleaning tower, the fence surrounds the 3D model, and the cleaning tower is located on one side of the 3D model;

[0041](5.1) Fence slicing: If y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com