A 3D printing clay extrusion device

An extrusion device and 3D printing technology, applied in the field of 3D printing, can solve the problems of expensive, complicated, and bulky printing equipment, and achieve the effects of stable printing, replaceable materials, and smooth filament output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

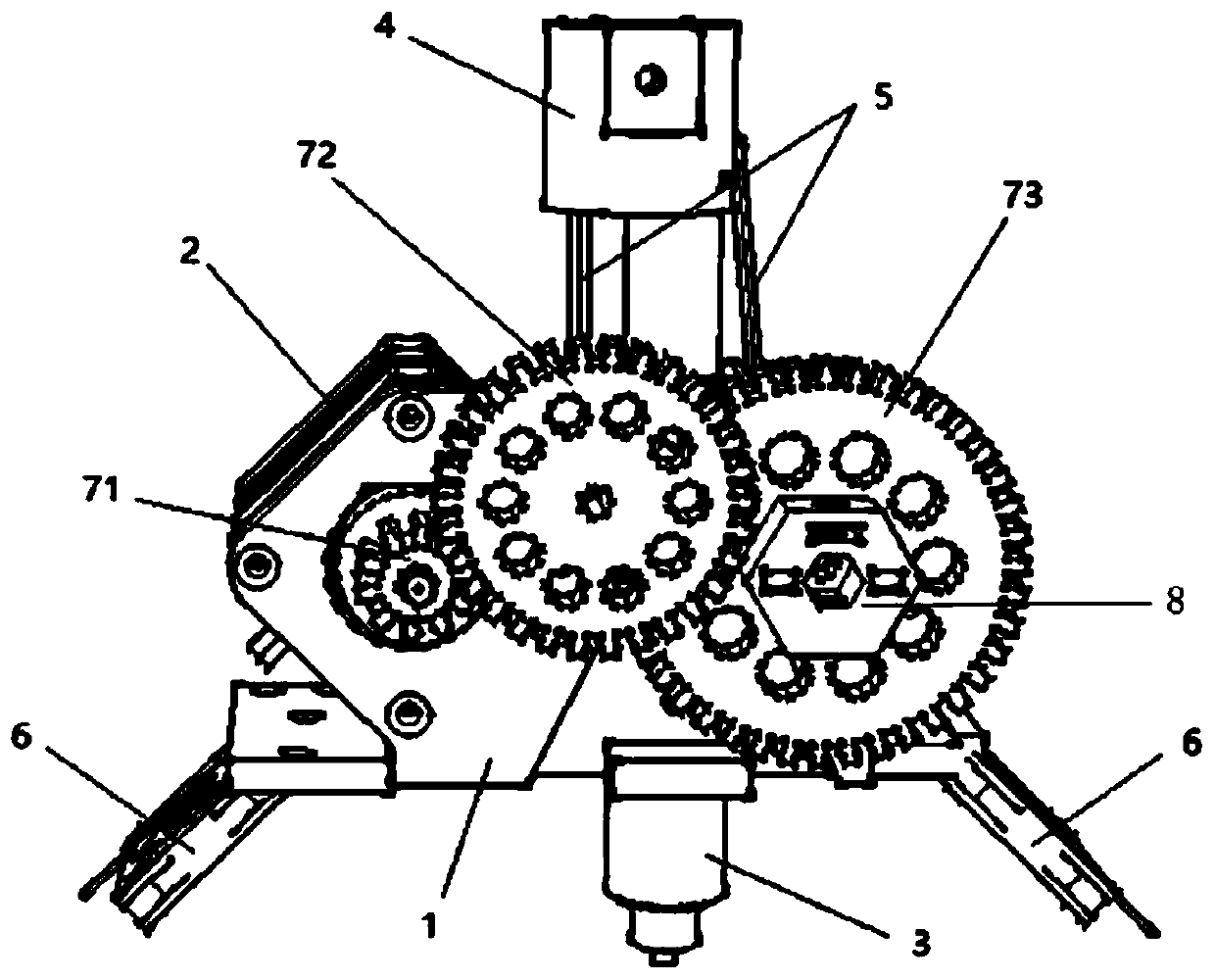

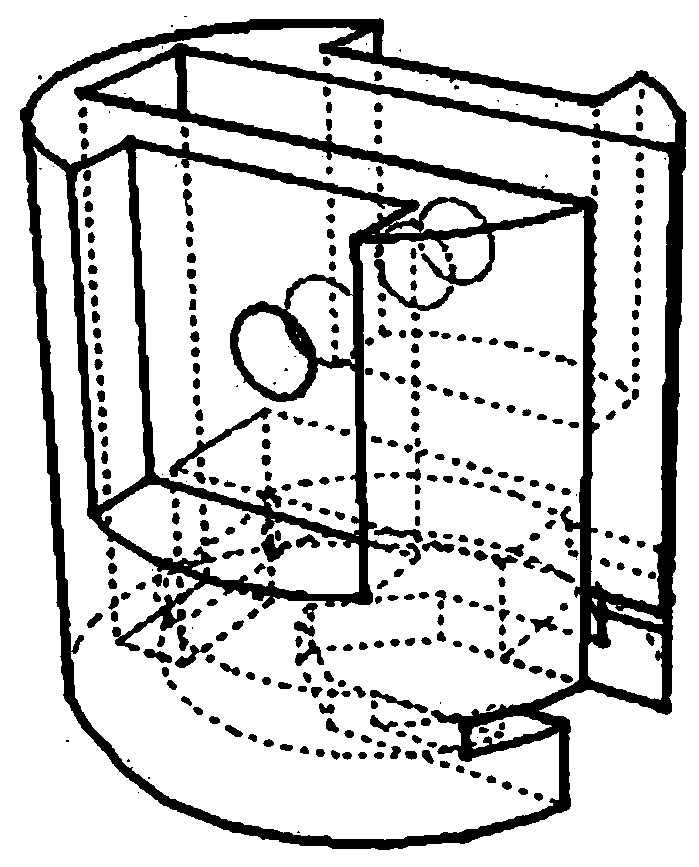

[0021] like figure 1 and figure 2 As shown, a 3D printing clay extrusion device includes a support base 1, a motor 2, a syringe 3, a piston slot 4, a timing belt 5, a fan 6, and gears. The support base 1 is the base for fixing the components of the whole device, and the motor 2 is a 12V42 stepper motor fixed on the upper left side of the support base 1, which is the power source for material extrusion. Described synchronous belt 5 is the rubber synchronous belt of wide 5mm, long 30cm. The syringe 3 runs through the middle of the support base 1, the clay material is contained in the syringe, the body of the syringe is fixed to the support base 1, the piston can move vertically, the piston cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com