A method for fire protection of wooden structural members

A technology of wooden structures and wooden components, applied in fire prevention, building components, anti-corrosion coatings, etc., to achieve the effects of improved fire resistance, ingenious design, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

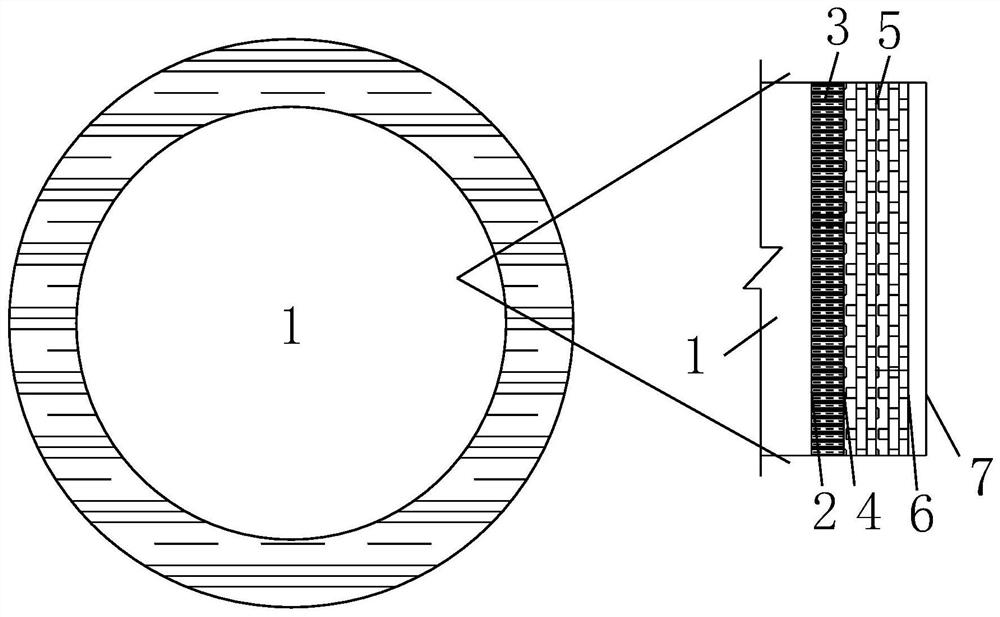

[0021] Such as Figure 1-Figure 2 As shown, first carry out the surface treatment of wooden components, remove the sundries on the surface of the components, polish the working surface and dust off the generated sawdust; apply a layer of anti-corrosion paint 2 on the working surface; after the anti-corrosion paint 2 is completely dry, apply the first layer Ash material 3, and scraped and trimmed to make it smooth; spread a layer of linen cloth 4 evenly on the ashes, and press the fluffy part with a board; immediately apply the second layer of ash material 5 after the hemp is completed; let it stand for two days, and wait for the ash material Apply the primer 6 after it is completely dry; apply the topcoat 7 the next day after the primer 6 is completed. Anti-corrosion paint is a self-drying liquid paint that is diluted with an organic solvent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com