Ruthenium-based catalyst activation and regeneration method and application thereof

A ruthenium-based catalyst, a catalyst technology, applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems such as activation and regeneration of ruthenium-based catalysts, decrease in catalyst activity, deactivation, etc. that have not yet occurred, To achieve the effect of improving the effective utilization rate, reducing the carbonization rate and improving the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

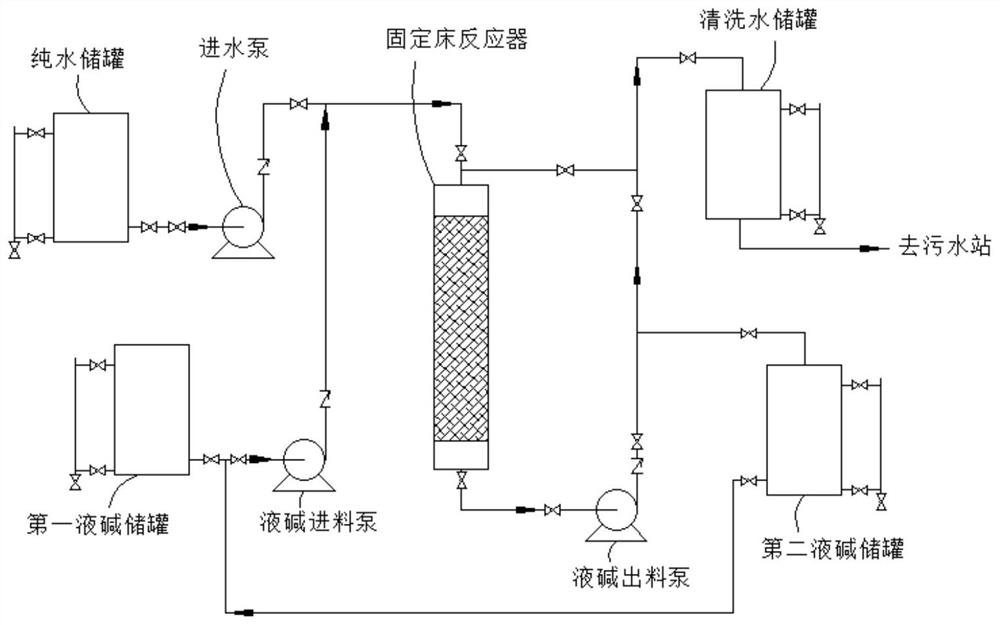

[0026] Embodiment 1: a kind of ruthenium-based catalyst activation regeneration method comprises:

[0027] S1. Fill the first liquid caustic soda storage tank with liquid caustic soda with a mass concentration of 20%, and pump it into the fixed bed reactor through the liquid caustic soda feed pump. When the liquid caustic soda level in the fixed bed reactor is higher than that of the catalyst After the bed is 10cm, the liquid caustic soda feed pump stops running;

[0028] S2. After controlling the liquid caustic soda to stay in the fixed-bed reactor for 5 hours, open the valve at the bottom of the fixed-bed reactor, and use the liquid caustic discharge pump to pump the liquid caustic containing impurities attached to the catalyst to the second liquid caustic storage tank;

[0029] S3. After the liquid alkali in the fixed bed reactor is drained, keep the liquid level in the pure water storage tank to 90% of the height of the pure water storage tank, and use the water inlet pump...

Embodiment 2

[0033]Embodiment 2: a kind of ruthenium-based catalyst activation regeneration method comprises:

[0034] S1. Pre-activate the catalyst layer in the fixed-bed reactor, raise the temperature of the fixed-bed reactor to 125°C, and then pass a mixed gas composed of nitrogen and hydrogen at a volume ratio of 1:3 into the fixed-bed reactor to control the gas The air speed is 2500h -1 , and then raise the temperature of the fixed-bed reactor to 180°C, and treat it at a constant temperature for 1 h; by preactivating the catalyst layer, the activity of the catalyst layer can be significantly improved, and the carbonization rate of the catalyst layer can be reduced at the same time, and then the first liquid alkali storage Fill the tank with liquid caustic soda with a mass concentration of 10%, and pump it into the fixed bed reactor through the liquid caustic feed pump. After the liquid caustic in the fixed bed reactor is higher than the catalyst bed by 5cm, the liquid caustic is fed ...

Embodiment 3

[0040] Embodiment 3: a kind of ruthenium-based catalyst activation regeneration method comprises:

[0041] S1. Pre-activate the catalyst layer in the fixed-bed reactor, raise the temperature of the fixed-bed reactor to 180°C, and then pass a mixed gas composed of nitrogen and hydrogen at a volume ratio of 1:5 into the fixed-bed reactor to control the gas Airspeed is 4800h -1 , and then raise the temperature of the fixed-bed reactor to 220°C, and treat it at a constant temperature for 3 hours; by preactivating the catalyst layer, the activity of the catalyst layer can be significantly improved, and the carbonization rate of the catalyst layer can be reduced at the same time; and then the first liquid alkali storage Fill the tank with liquid caustic soda with a mass concentration of 15%, and pump it into the fixed bed reactor through the liquid caustic feed pump. Stop the pump; finally add additives to the fixed bed reactor, the dosage of additives is 5% of the volume of liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com