Camera lens machining method

A lens processing and camera technology, which is applied to metal processing equipment, lenses, manufacturing tools, etc., can solve the problems of low hole yield rate and large error of camera lens shape, so as to improve the stability of installation, reduce workload, and align accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

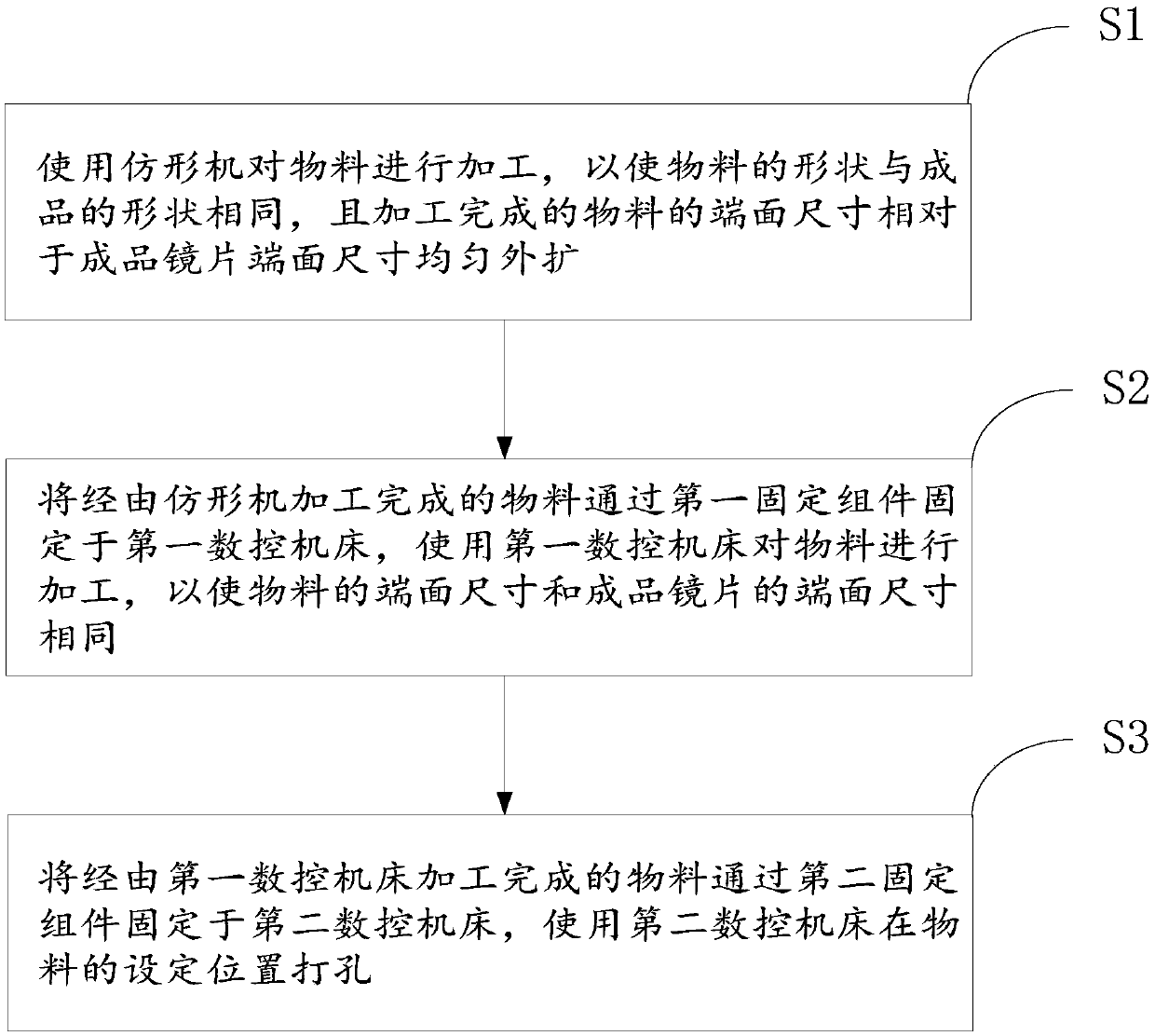

[0036] Such as figure 1 with figure 2 As shown, the camera lens processing method provided by the embodiment of the present invention includes:

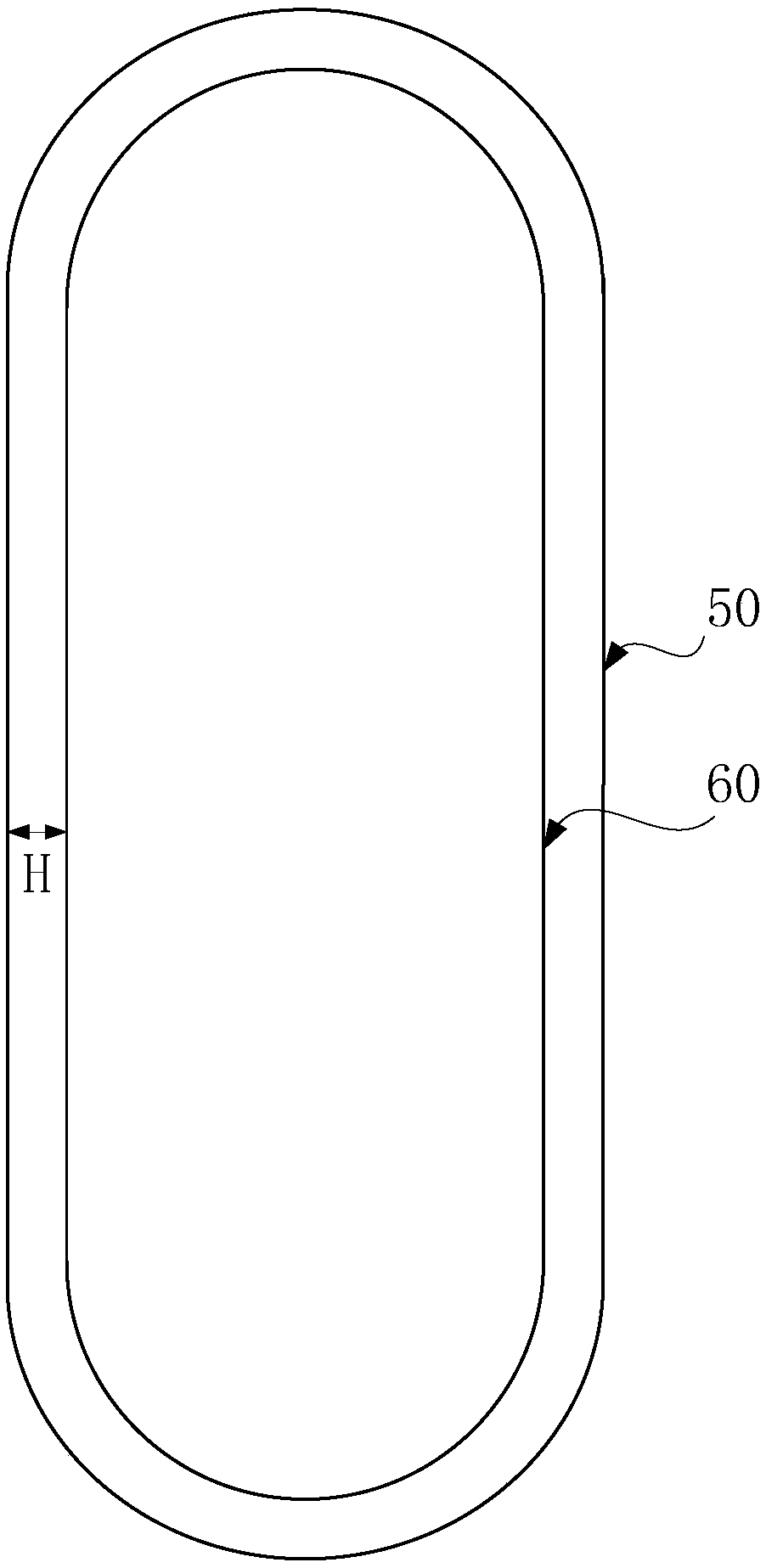

[0037] S1. Process the material 50 using a profiling machine so that the shape of the material 50 is the same as that of the finished product, and the size of the end surface of the processed material 50 is evenly expanded relative to the size of the end surface of the finished lens 60;

[0038] S2. Fix the material 50 processed by the profiling machine on the first numerical control machine tool through the first positioning assembly, and use the first numerical control machine tool to process the material 50 so that the end face size of the material 50 is the same as the end face size of the finished lens 60 ;

[0039] S3. Fix the material 50 processed by the first numerical control machine tool on the second numerical control machine tool through the second positioning component, and use the second numerical control machine too...

Embodiment 2

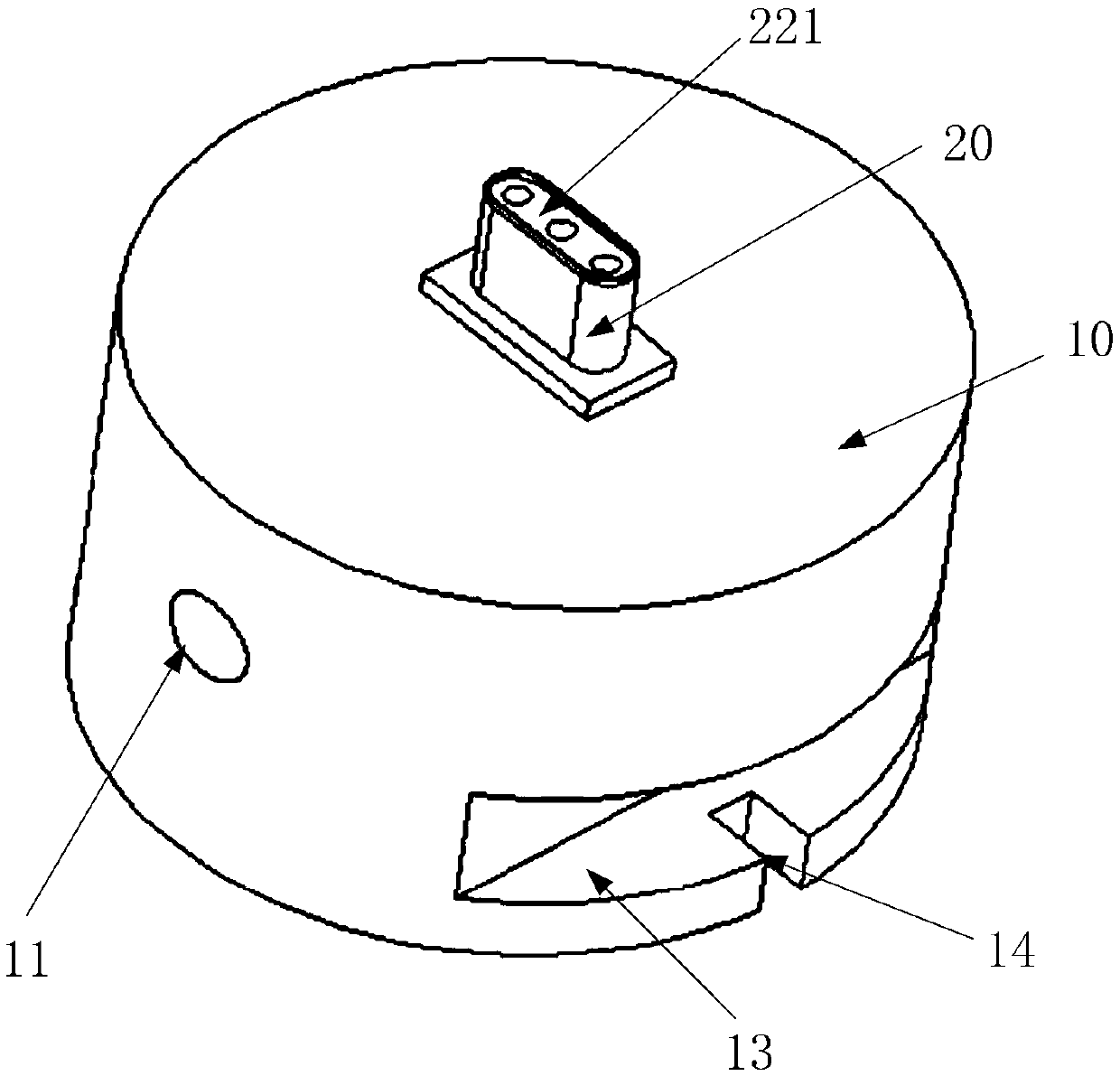

[0050] Embodiment 2 of the present invention will refer to the appended image 3 - attached Figure 9 , to further explain the structures of the first positioning component and the second positioning component used in the camera processing method provided in the first embodiment above.

[0051] The first positioning assembly is used to fix the material to the first numerical control machine tool, and the first positioning assembly is provided with a first suction hole 12 and a first suction mechanism connection port 11 communicating with the first suction hole 12 . During use, the first positioning assembly is fixed to the first CNC machining machine tool, and then the connecting pipe of the first suction mechanism is communicated with the first suction hole 12, and the material is placed on the top surface of the first positioning assembly, and the opening The first suction mechanism fixes the material with the first positioning component.

[0052] In a specific implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com