Molding process of beer can screw cap

A molding process, a technology for beer cans, applied in the directions of molding tools, capping, manufacturing tools, etc., can solve problems such as affecting food safety, metal containers are susceptible to corrosion, etc., and achieve the effects of simple production process, reliable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

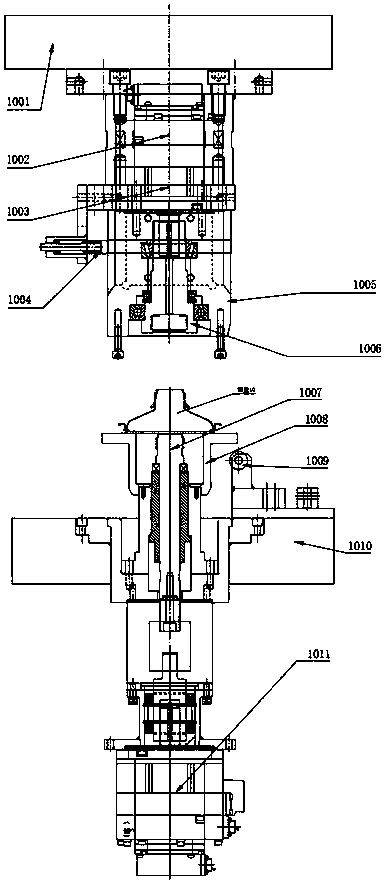

[0029] The present invention aims to provide a molding process for beer can screw caps. The process uses film-coated metal as raw material. According to the characteristics of the material, after a large number of tests, a method suitable for preparing beer can screw caps with film-coated metal as raw material is obtained. Cover production process.

[0030] A kind of beer can screw cap molding process of the present invention, comprises:

[0031] Step 1 101: Stamping and stretching the sheared blank into a beer can screw cap blank;

[0032] In step one 101, the upper notch die and the lower notch die cooperate with each other to cut the material into the required size of the blank, and then punch and draw the cut blank through the upper forming die and the lower forming die of the basic cover stamping machine Stretch into beer can screw cap blank.

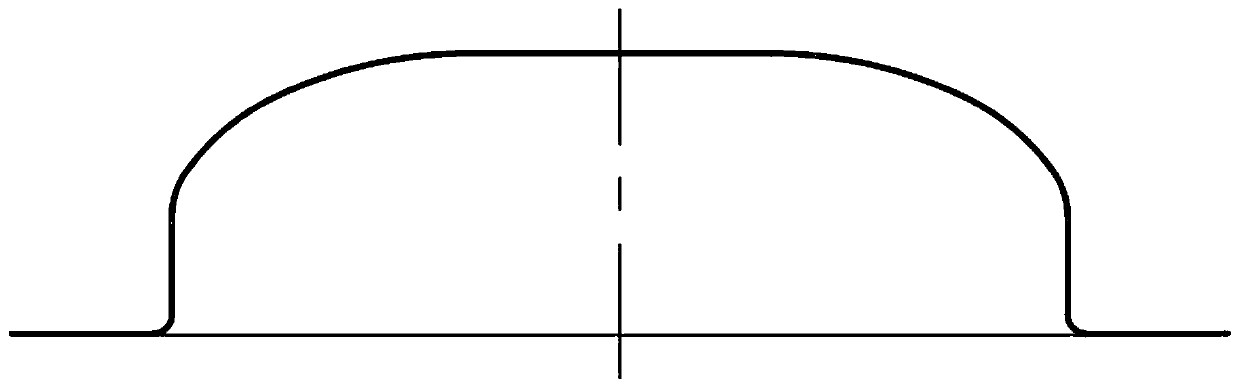

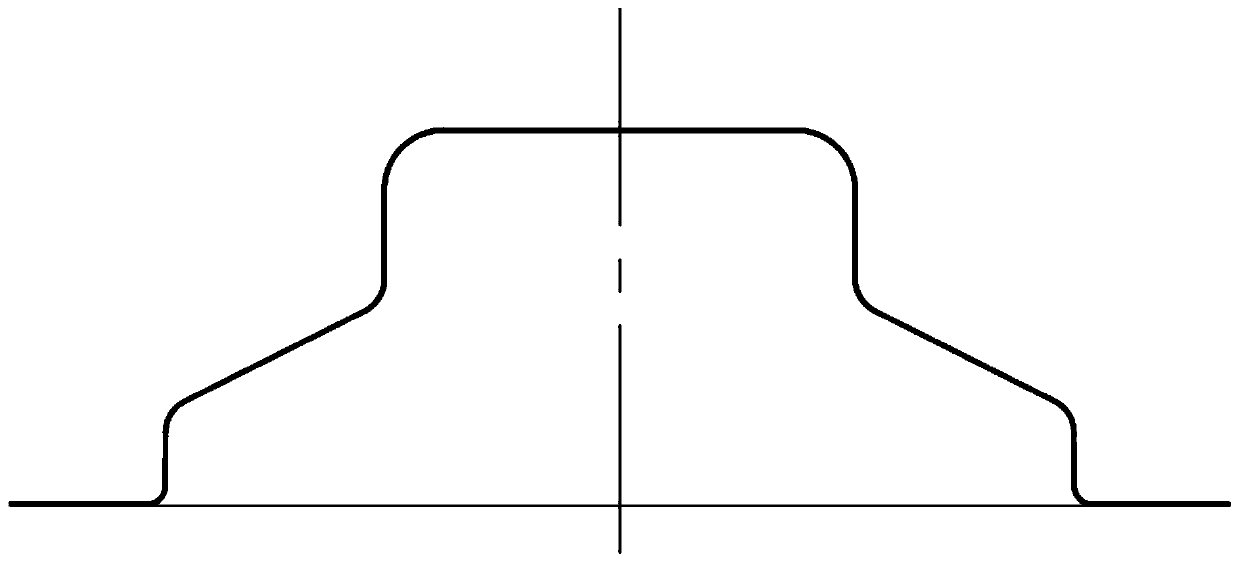

[0033] The shape of the beer can screw cap blank obtained by stretching is a hollow shallow disk with one end open.

[0034] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com