Composite all-welded aluminum honeycomb core waveguide window and production process thereof

A production process, aluminum honeycomb technology, applied in waveguide-type devices, electrical components, projection rooms/rooms, etc., can solve the problems of poor shielding efficiency, metal materials cannot meet its requirements, limited application occasions, etc., to improve shielding efficiency. , The product has a wide range of applications, and the effect of enhancing the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

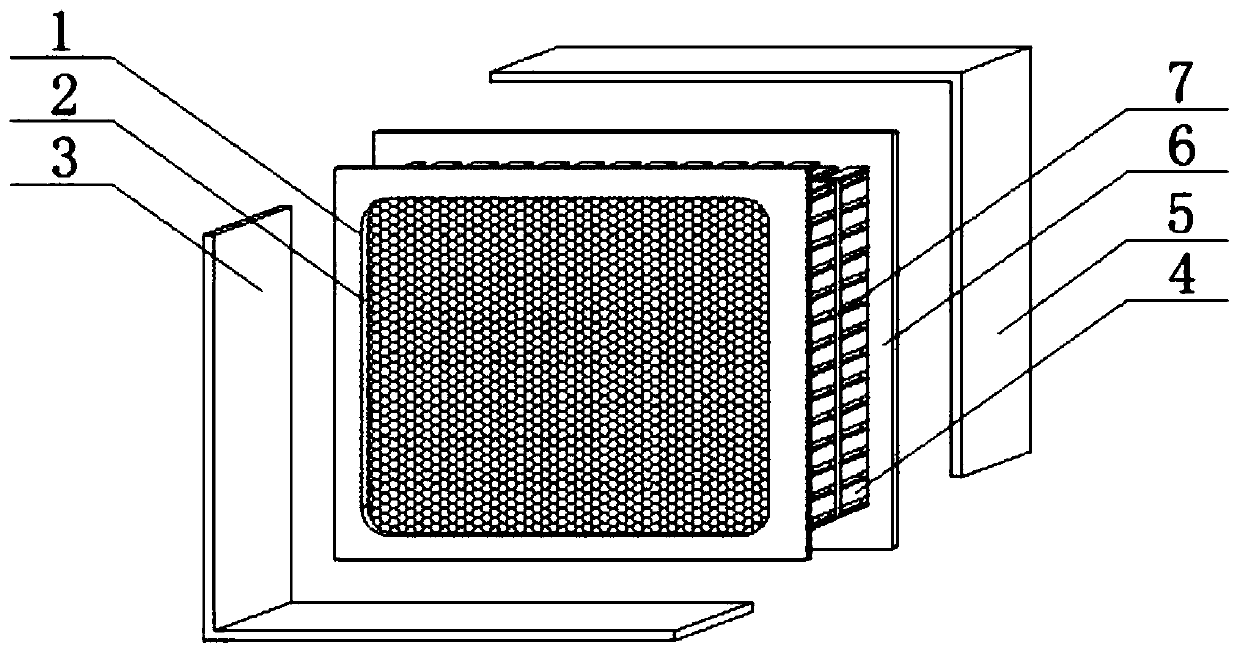

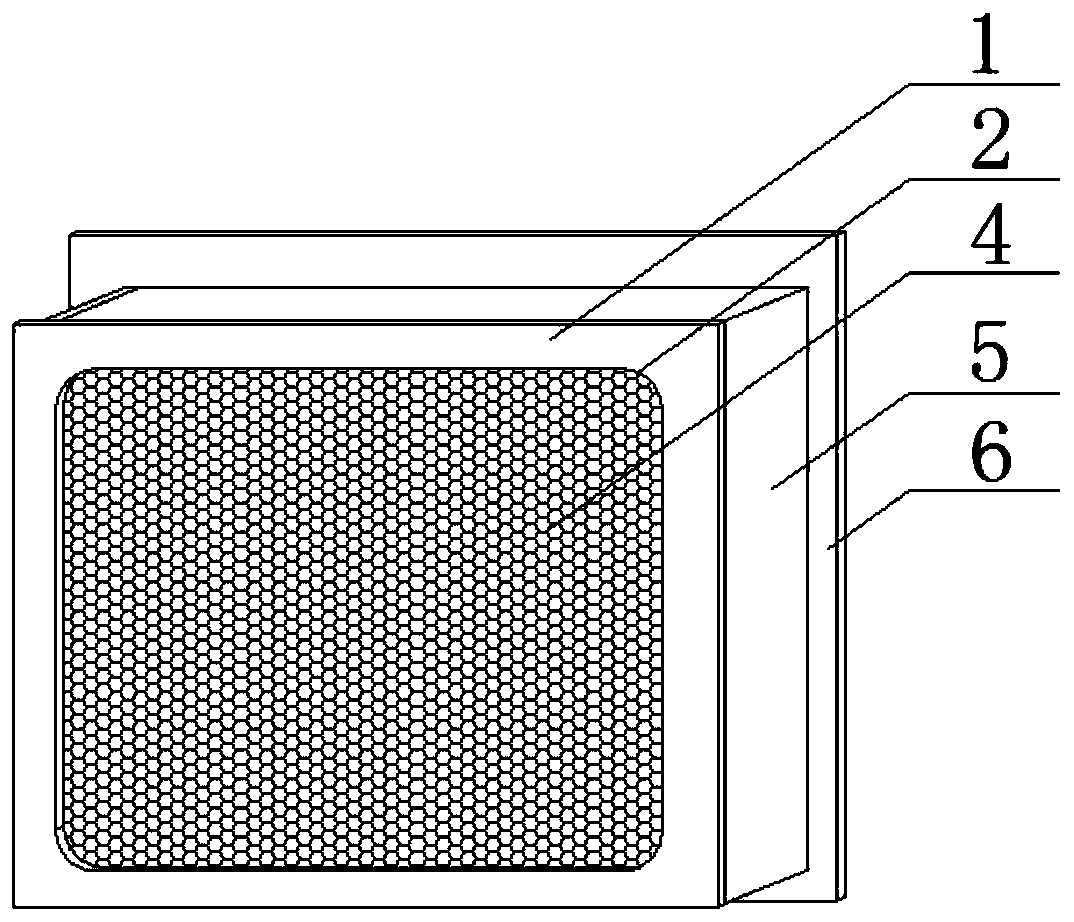

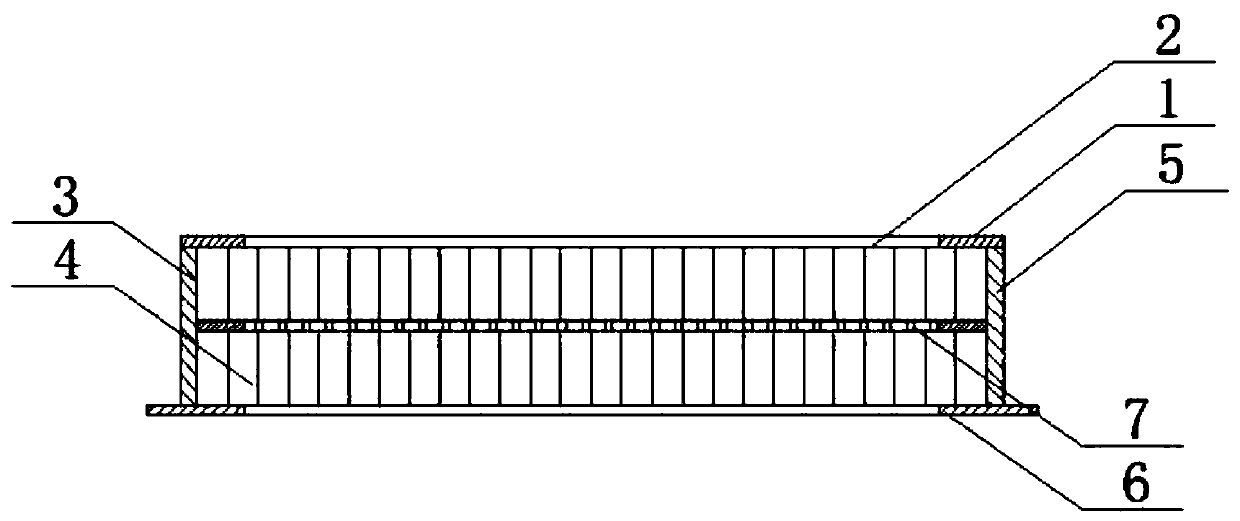

[0041] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

[0042] plan 1

[0043] Reference figure 1 , 2 , 3, 4, 5, the production process steps of a composite fully welded aluminum honeycomb core waveguide window:

[0044] S1. Calculate the waveguide depth according to the electromagnetic field shielding performance requirements required by the customer, select the side length of the honeycomb core 4, the height of the honeycomb core 4, and the aluminum foil thickness of the aluminum honeycomb core. The selected aluminum foil is an aluminum composite material, and the brazing filler metal Laminated on the surface of aluminum foil;

[0045] S2. According to the requirements of the multi-cell structure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com