Preparation method of aromatic, antibacterial and waterproof non-woven fabric

A non-woven fabric and aromatic technology, applied in textiles and papermaking, conjugated artificial filaments, conjugated synthetic polymer artificial filaments, etc., can solve problems such as swelling and disintegration, and achieve improved stability and antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

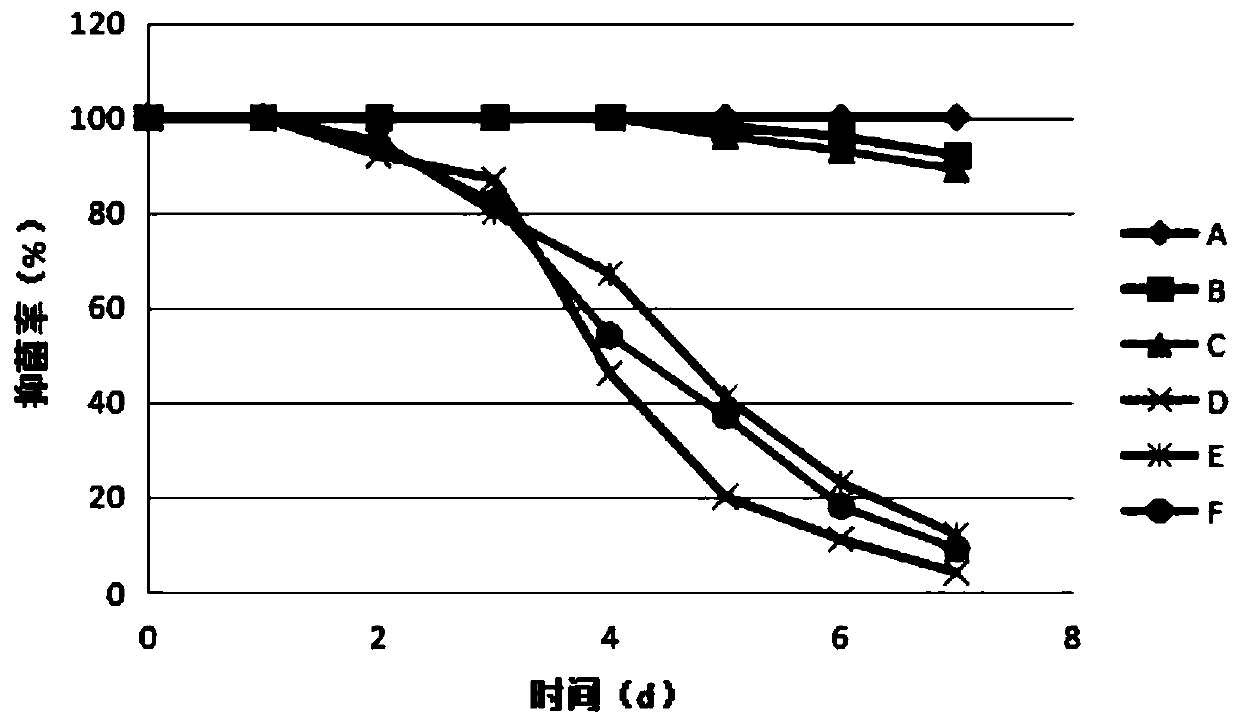

Examples

preparation example Construction

[0031] A method for preparing an aromatic antibacterial waterproof nonwoven fabric, comprising the steps of:

[0032] S1: Weigh the organic-inorganic composite lipid and antibacterial agent with a mass ratio of (0.1-0.2):(1-3), dissolve the organic-inorganic composite lipid in chloroform, evaporate and remove the chloroform To obtain a lipid-like film, add an antibacterial agent to the lipid-like film, stir and mix evenly, and rapidly heat to 45-50°C, maintain it for 10-30s while performing ultrasound in a water bath, then cool to 4°C and let it stand still. Extrude through a liposome extruder to obtain an antibacterial siliceous solution;

[0033] S2: Dissolving chitosan and polyethylene oxide completely in 90v / v% acetic acid solution, stirring evenly, to obtain spinning solution;

[0034] S3: using the spinning solution to perform electrospinning to obtain chitosan / polyethylene oxide nanofibers;

[0035] S4: immersing the nanofibers obtained in step S3 into the antibacteri...

Embodiment 1

[0052] A method for preparing an aromatic antibacterial waterproof nonwoven fabric, comprising the steps of:

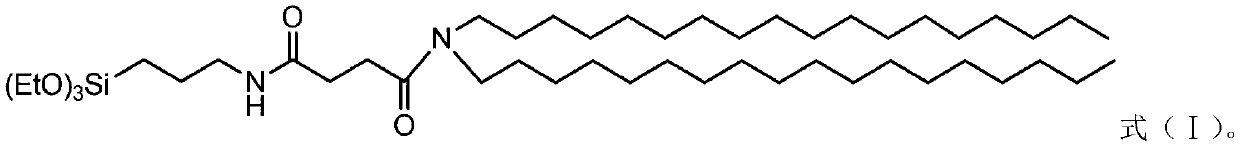

[0053] 1. Preparation of organic-inorganic composite lipid: Dissolve 15g of N,N-bis(octadecylpropylamino)glycine in 100ml of triethylamine, then add 15g of aminopropyltriethoxysilane, and add at 0°C 6g of condensation reagent benzotriazol-1-yl-oxytripyrrolidinyl phosphonium hexafluorophosphate (PyBOP) was reacted for 6h, and after the reaction was completed, the organic-inorganic composite lipid was collected by silica gel column chromatography;

[0054] 2. Preparation of antibacterial siliceous body: Weigh 0.15g organic-inorganic composite lipid, dissolve organic-inorganic composite lipid in 10ml chloroform, remove chloroform by evaporation to obtain lipid-like film; dissolve 100ml 30g / L Add the tea tree essential oil solution into the obtained lipid film, stir and mix well, and rapidly heat up to 50°C, heat shock for 20s while ultrasonically in a water bath, cool to...

Embodiment 2

[0061] A method for preparing an aromatic antibacterial waterproof nonwoven fabric, comprising the steps of:

[0062] 1. Preparation of organic-inorganic composite lipid: Dissolve 10g of N,N-bis(octadecylpropylamino)glycine in 100ml of pyridine, then add 10g of aminopropyltriethoxysilane, and add 4g of it at -10°C The condensation reagent dicyclohexylcarbodiimide (DCC) was reacted for 4 hours, and after the reaction was completed, the organic-inorganic composite lipid was collected by silica gel column chromatography;

[0063] 2. Preparation of antibacterial siliceous body: Weigh 0.1g organic-inorganic composite lipid, dissolve organic-inorganic composite lipid in 10ml chloroform, remove chloroform by evaporation to obtain lipid-like film; dissolve 150ml 20g / L Add the eucalyptus essential oil solution into the obtained lipid film, stir and mix well, then heat rapidly to 45°C, heat shock for 10s while ultrasonically in a water bath, cool to 4°C, let stand, and extrude through p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com