Preparation method for cotton fabric with bactericidal and bacteriostatic functions, and prepared fabric

A cotton fabric and functional technology, applied in biochemical fiber treatment, textiles and papermaking, fiber treatment, etc., can solve the problems of undiscovered antibacterial fabrics, unfit personal clothing, and fabrics that are not washable, so as to reduce property losses and have good antibacterial effects , good hygienic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

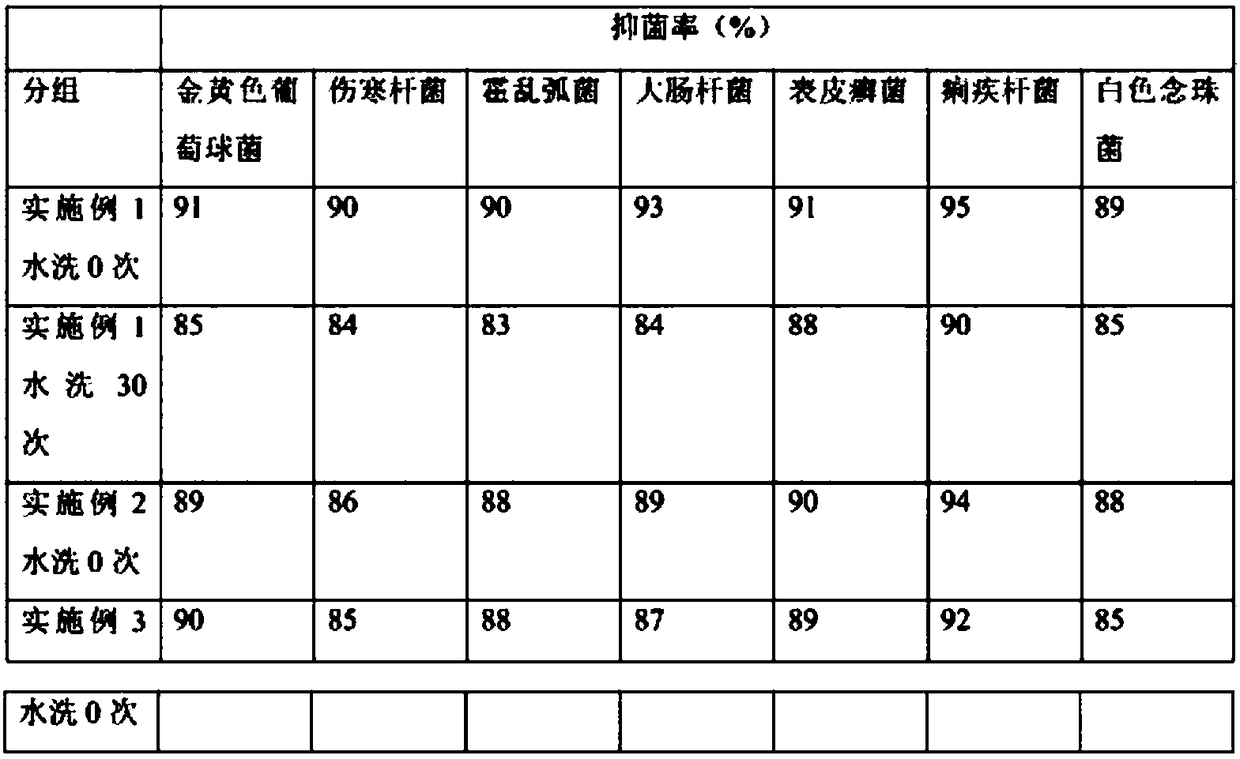

Examples

Embodiment 1

[0030] Extract berberine: crush 1kg of berberine into powder, pass through a 40-mesh sieve, add 6kg of ethanol aqueous solution with a mass fraction of 45%, and conduct ultrasonic extraction for 1.5 hours at a temperature of 75°C. The ultrasonic frequency is 28KHZ. After extraction, filter and take the filtrate. To obtain the berberine extract, add concentrated hydrochloric acid to adjust the pH=2, stir continuously, cool down to 5°C, let it stand for 16 hours, filter to obtain crude product crystals, recrystallize with water, and filter to obtain 11.6 g of berberine;

[0031] Preparation of antibacterial fabric: take 240g of cotton fiber, place it in 4.8kg of NaOH aqueous solution with a pH of 8.5, and soak it for 1 hour at a water bath temperature of 35°C; wash the soaked cotton fiber to neutral, add 4.8g of berberine, Add water, bath ratio 1:20, feed nitrogen, react at 60°C for 10 minutes, then raise to 80°C at 2°C / min, keep warm for 20 minutes, take it out and dry at 60°C ...

Embodiment 2

[0033] Extract berberine: crush 1kg of berberine into powder, pass through a 40-mesh sieve, add 5kg of ethanol aqueous solution with a mass fraction of 40%, and conduct ultrasonic extraction for 1 hour at a temperature of 70°C, with an ultrasonic frequency of 25KHZ. After extraction, filter and take the filtrate. To obtain the berberine extract, add concentrated hydrochloric acid to adjust the pH=1, stir continuously, cool down to 0°C, let it stand for 12 hours, filter to obtain crude product crystals, recrystallize with water, and obtain 9.4 g of berberine by filtration;

[0034] Preparation of antibacterial fabrics: Weigh 240g of cotton fiber, place it in 4.8kg of NaOH aqueous solution with a pH of 8.5, and soak it for 1 hour at a water bath temperature of 30°C; wash the soaked cotton fiber to neutral, add 5g of berberine, add water , bath ratio 1:20, feed nitrogen, react at 60°C for 10 minutes, then increase to 80°C at 2°C / min, keep warm for 20 minutes, take it out and place...

Embodiment 3

[0036] Extract berberine: crush 1kg of berberine into powder, pass through a 40-mesh sieve, add 8kg of ethanol aqueous solution with a mass fraction of 50%, and conduct ultrasonic extraction for 2 hours at a temperature of 80°C. The ultrasonic frequency is 40KHZ. After extraction, filter and take the filtrate. To obtain the berberine extract, add concentrated hydrochloric acid to adjust the pH=1.5, stir continuously, cool down to 10°C, let stand for 24 hours, filter to obtain crude product crystals, recrystallize with water, and filter to obtain 10.7 g of berberine;

[0037] Preparation of antibacterial fabric: take 240g of cotton fiber, place it in 4.8kg of NaOH aqueous solution with a pH of 8.5, and soak it for 1.5 hours at a water bath temperature of 40°C; wash the soaked cotton fiber to neutral, add 7g of berberine, add water , bath ratio 1:20, feed nitrogen, react at 60°C for 10 minutes, then increase to 80°C at 2°C / min, keep warm for 20 minutes, take it out and place it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com