Making and storage technology of antibacterial and washable linen fabric

A manufacturing process and linen technology, which is applied in the field of production and preservation of linen fabrics, can solve the problems of decreased washability, damaged linen fabrics, and shortened service life of users, so as to increase the washability and storage time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

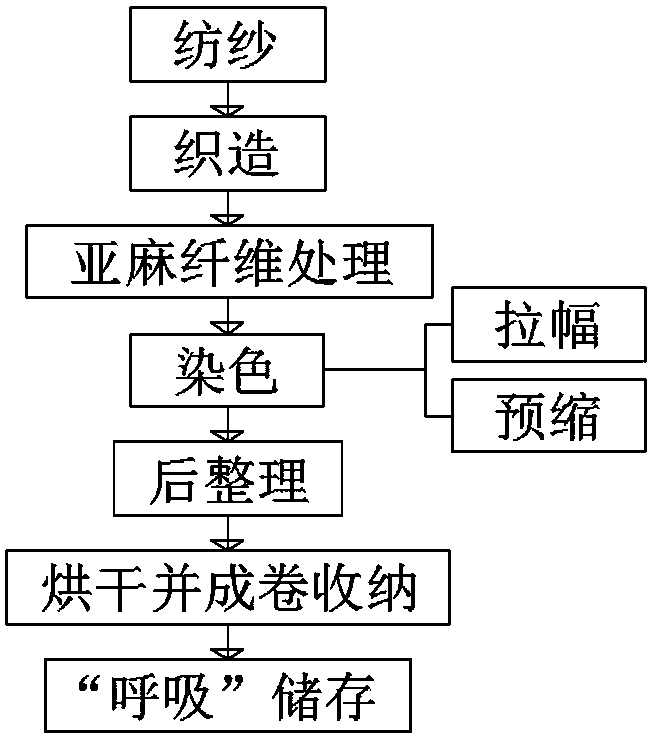

[0051] A production and preservation process of an antibacterial and washable linen fabric, including the production process and preservation process of the linen fabric:

[0052] Step 1, processing the flax raw material to obtain the yarn therein;

[0053] Step 2, weaving the obtained yarn into cloth on a loom;

[0054] Step 3: Carry out fiber treatment to cloth, wherein main step is chlorine bleaching, and chlorine bleaching can remove hemp skin, lignin etc. in flax fiber;

[0055] Step 4. Dye the cloth according to the production needs. At the same time, during the dyeing process, the cloth is stretched and pre-shrunk. Dyeing can make the linen cloth show color, the stretcher can maintain the stability of the fabric size, and the pre-shrinking can ensure the fabric The shrinkage rate is within a certain range;

[0056] Step 5. After the above steps are completed, perform air washing / enzyme washing and other operations on the cloth. After the treatment, the fabric feels ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com