Preparation method of 3D tissue engineering cell ring

A tissue engineering and cell technology, applied in the field of cell engineering, can solve the problems of geometric size gap, complicated operation process, scaffolds affecting cell growth and differentiation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

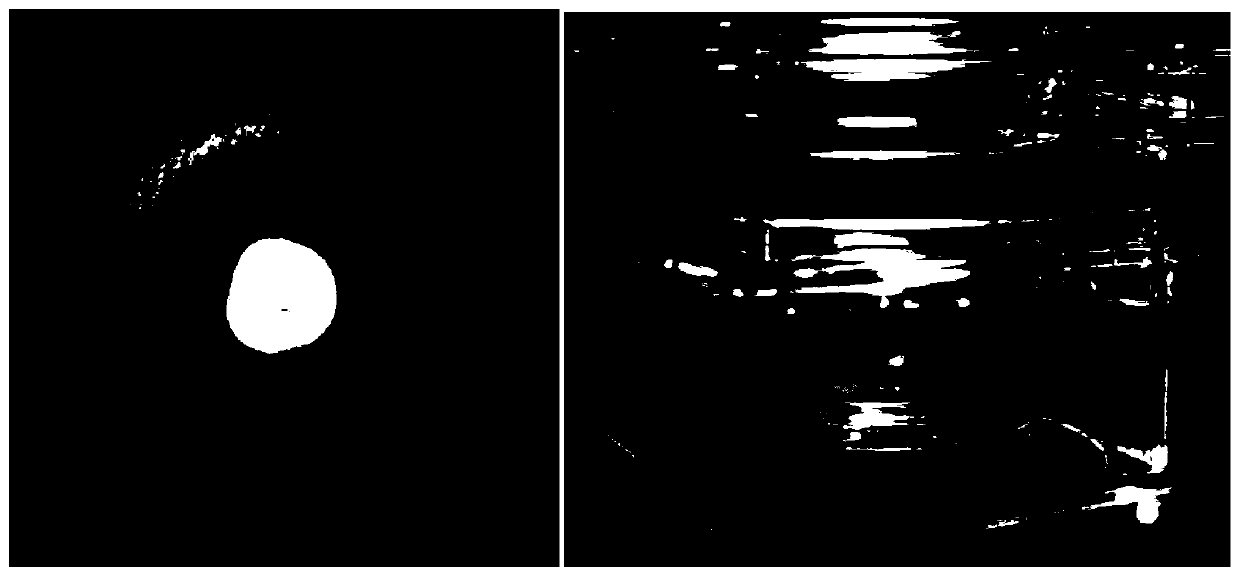

Image

Examples

Embodiment 1

[0117] Example 1: Human osteosarcoma 143b cell ring (the preparation method of human lung cancer A549 cell ring and human nasopharyngeal carcinoma S18 cell ring is the same as that of osteosarcoma)

[0118] A preparation method of human osteosarcoma 143b cell ring, comprising the following steps:

[0119] a. Prepare ring culture medium: add 0.25% methylcellulose to high-sugar DMEM basic medium, add 10% FBS, 10ng / mlbFGF, 10ng / ml PDGF, 20ng / ml TGFβ, 10uM Y-27632;

[0120] b. Put the low-temperature sterilized cell ring culture mold into a 24-well culture plate;

[0121] c. Add 40 microliters of anti-adhesion coating to the culture well and incubate at room temperature for 30 minutes;

[0122] d. Aspirate the anti-adhesion coating, and rinse the groove of the culture well with room temperature DMEM medium for 30 minutes;

[0123] e. Suck out the DMEM base, and the mold is ready for use;

[0124] f. After the 143b osteosarcoma and human epidermal fibroblasts grow to 95% saturatio...

Embodiment 2

[0132] Example 2: Human giant cell tumor of bone stromal cell ring (the preparation method of rat adipose stem cell ring is the same as that of giant cell tumor of bone)

[0133] A method for preparing a human giant cell tumor stromal cell ring, comprising the following steps:

[0134] a. Prepare ring culture medium: add 0.25% methylcellulose to high-sugar DMEM basic medium, add 10% FBS, 10ng / mlbFGF, 10ng / ml PDGF, 20ng / ml TGFβ, 10uM Y-27632;

[0135] b. Put the low-temperature sterilized cell ring culture mold into a 24-well culture plate;

[0136] c. Add 40 microliters of anti-adhesion coating to the culture well and incubate at room temperature for 30 minutes;

[0137] d. Aspirate the anti-adhesion coating, and rinse the groove of the culture well with room temperature DMEM medium for 30 minutes;

[0138] e. Suck out the DMEM base, and the mold is ready for use;

[0139] f. After the 143b giant cell tumor cells grow to 95% saturation, digest the cells with 0.5% trypsin to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com