Styrene storage tank VOCs safety recovery system and recovery process

A recovery system and styrene technology, which is applied in the recovery of liquid hydrocarbon mixtures, petroleum industry, packaging, etc., can solve the problems of storage tanks exceeding the pressure range, large nitrogen consumption, and large dependence on pressure sensors, so as to save nitrogen consumption and improve the treatment effect Excellent, increase the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention proposes a styrene storage tank VOCs safe recovery system and recovery process. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

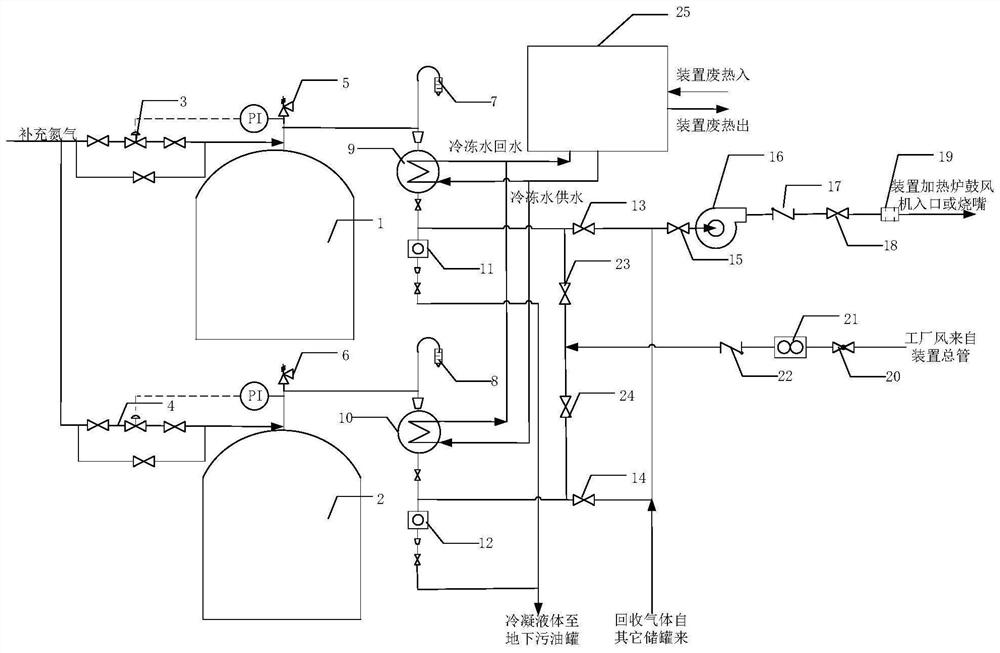

[0031] Such as figure 1 As shown, the styrene storage tank VOCs safe recovery system of the present invention includes a styrene atmospheric storage tank one 1, a styrene atmospheric pressure storage tank two 2, a suction cryocooler one 9, a suction cryocooler two 10, Suction coolant window 11, suction coolant window 2 12, first breathing valve 5, second breathing valve 6, first suction port muffler 7, second suction port muffler 8, suction wind 16 And flame arrester 19.

[0032] The exhaust port of the styrene atmospheric storage tank one 2 is connected to the suction fan 16 through the first pipeline, and the suction cryocooler one is installed on the first pipeline, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com