Nanometer lignocellulose/graphite-like phase carbon nitride composite material and preparation method thereof, and applications in woodware coating materials

A graphite phase carbon nitride and lignocellulose technology, applied in the field of coatings, can solve the problems of good wear resistance and high hardness of water-based wood paint bombs, and achieve the effects of improving stain resistance, strong weather resistance and weather resistance, and enhanced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

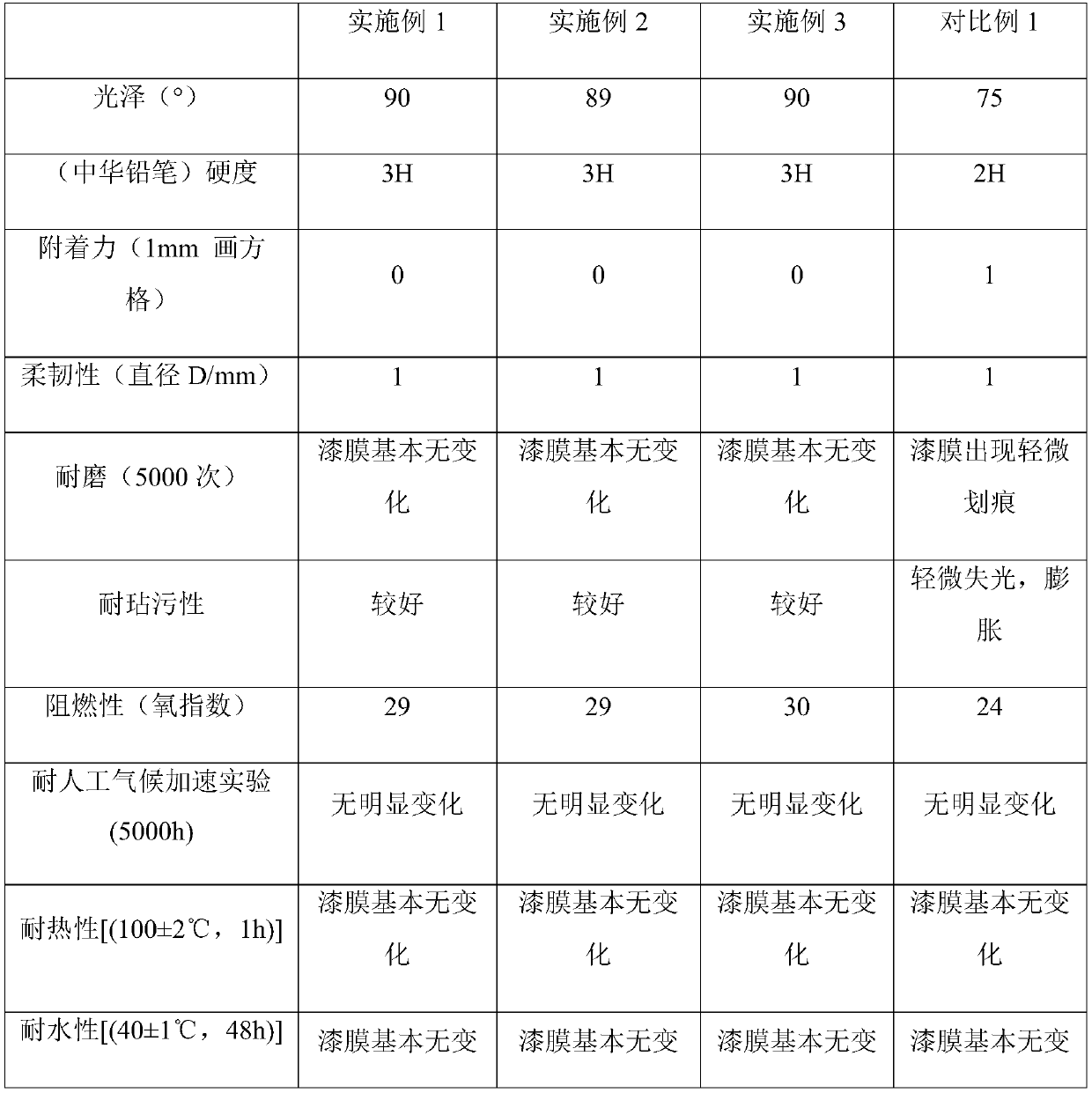

Examples

Embodiment 1

[0062] 1. Preparation of nano-lignocellulose / graphite-like carbon nitride composites

[0063] (1) Preparation of nanometer lignocellulose:

[0064] Add 1g of lignocellulose into 140mL of deionized water, disperse evenly, add 0.02g of 2,2,6,6-tetramethyl-1-piperidine oxidant and 0.3g of sodium bromide, mix evenly to obtain a homogeneous solution , add 14mmol / L sodium hypochlorite solution to trigger the oxidation reaction, adjust the pH to 10-11 with 0.5mol / L KOH solution, react at 30°C for 3h, add 0.5mol / L HCl solution to adjust the pH to 6.8-7.2, centrifuge, Wash to obtain nanometer lignocellulose.

[0065] (2) Prepare the modified nano lignocellulose of core-shell structure:

[0066] In step a, add 3.2 g of polyvinylpyrrolidone and 0.4 g of nano lignocellulose into 100 mL of deionized water, and disperse evenly to obtain the first mixed dispersion;

[0067] Step b, 20gFeCl 3 ·6H 2 O was dissolved in 120 mL of deionized water to obtain a ferric chloride solution, and at ...

Embodiment 2

[0081] 1. Preparation of nano-lignocellulose / graphite-like carbon nitride composites

[0082] (1) Preparation of nanometer lignocellulose:

[0083] Add 3g of lignocellulose into 130mL of deionized water, disperse evenly, add 0.04g of 2,2,6,6-tetramethyl-1-piperidine oxidant and 0.2g of sodium bromide, mix evenly to obtain a homogeneous solution , add 10mmol / L sodium hypochlorite solution to trigger the oxidation reaction, adjust the pH to 10-11 with 0.7mol / L KOH solution, react at 25°C for 4h, add 0.7mol / L HCl solution to adjust the pH to 6.8-7.2, centrifuge, Wash to obtain nanometer lignocellulose.

[0084] (2) Prepare the modified nano lignocellulose of core-shell structure:

[0085] In step a, add 6 g of polyvinylpyrrolidone and 0.6 g of nano lignocellulose into 100 mL of deionized water, and disperse evenly to obtain the first mixed dispersion;

[0086] Step b, 30gFeCl 3 ·6H 2 O was dissolved in 80 mL of deionized water to obtain a ferric chloride solution, and the fe...

Embodiment 3

[0096] 1. Preparation of nano-lignocellulose / graphite-like carbon nitride composites

[0097] (1) Preparation of nanometer lignocellulose:

[0098] Add 2g of lignocellulose into 160mL of deionized water, disperse evenly, add 0.01g of 2,2,6,6-tetramethyl-1-piperidine oxidant and 0.1g of sodium bromide, mix evenly to obtain a homogeneous solution , add 12mmol / L sodium hypochlorite solution to trigger the oxidation reaction, adjust the pH to 10-11 with 0.3mol / L KOH solution, react at 20°C for 5h, add 0.3mol / L HCl solution to adjust the pH to 6.8-7.2, centrifuge, Wash to obtain nanometer lignocellulose.

[0099] (2) Prepare the modified nano lignocellulose of core-shell structure:

[0100] In step a, add 4.5g of polyvinylpyrrolidone and 0.5g of nano lignocellulose into 100mL of deionized water, and disperse evenly to obtain the first mixed dispersion;

[0101] Step b, 25gFeCl 3 ·6H 2 O was dissolved in 100 mL of deionized water to obtain a ferric chloride solution, and the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com