Carbon nanotube/polyaniline composite material and preparation method thereof

A carbon nanotube and composite material technology, which is applied in the field of carbon nanotube/polyaniline composite material and its preparation, can solve the problems of carbon nanotube damage, affecting the electrical, thermal and mechanical properties of carbon nanotubes, so as to ensure electrical conductivity. , The preparation process is simple, the effect of ensuring the structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of carbon nanotube / polyaniline composite material, comprises the following steps:

[0032] Dispersing the carbon nanotubes in an organic solvent to obtain a carbon nanotube dispersion;

[0033] A polyaniline solution is added to the carbon nanotube dispersion liquid, and a carbon nanotube / polyaniline composite material is obtained after solid-liquid separation.

[0034] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known in the art.

[0035] The invention disperses the carbon nanotube into the organic solvent to obtain the carbon nanotube dispersion liquid. In the present invention, the carbon nanotubes preferably include single-wall carbon nanotubes and / or multi-wall carbon nanotubes. The present invention has no special requirements on the size specification of the carbon nanotubes, and carbon nanotubes of any size specification are acceptable....

Embodiment 1

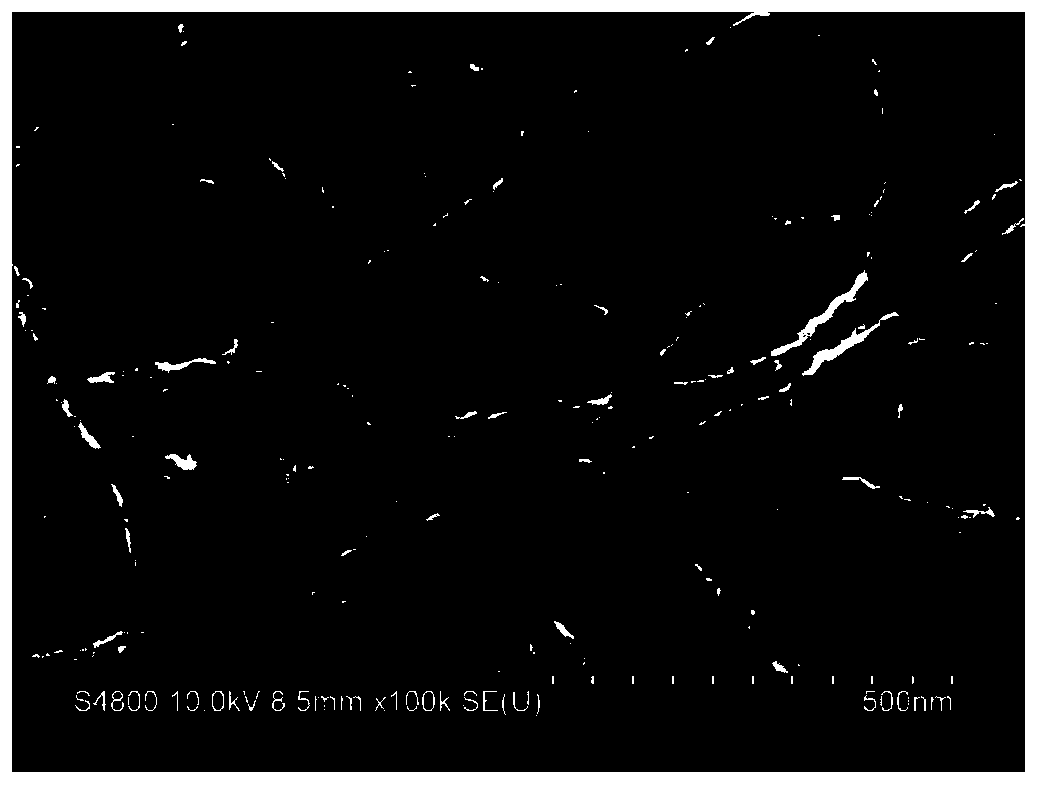

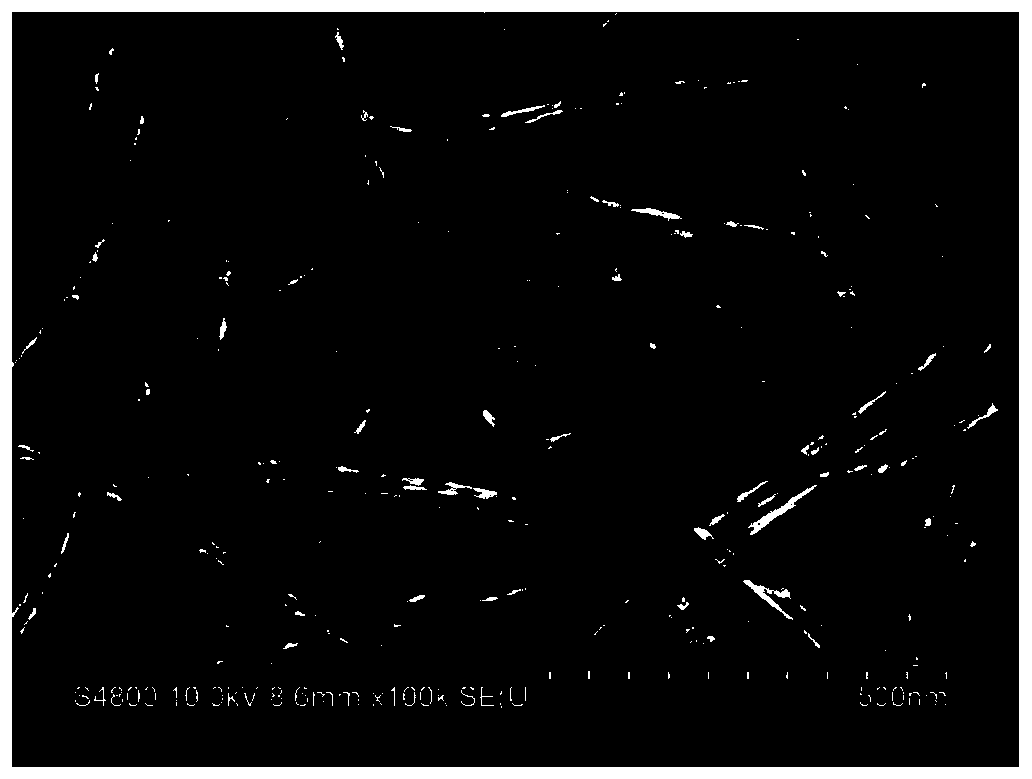

[0049] Weigh 0.4g of benzenesulfonic acid and dissolve it in 40mL of 1,3-dimethyl-2-imidazolidinone, add 40mg of single-walled carbon nanotubes after complete dissolution, stir at room temperature at a speed of 300r / min while ultrasonicating for 30min, A dispersion of single-walled carbon nanotubes was obtained. Then, weigh 40 mg of intrinsic state polyaniline (the corresponding monomer is aniline) and dissolve it in 100 mL of 1,3-dimethyl-2-imidazolidinone. In the dispersion liquid, and continue to ultrasonic and stir for 30min, so that the single-walled carbon nanotubes are uniformly dispersed again after adding polyaniline. After the ultrasound is completed, the carbon nanotube / polyaniline composite material with a mass ratio of single-walled carbon nanotubes and polyaniline of 1:1 can be obtained by suction filtration and washing, which is denoted as (1SWCNT-BSA)@1PANI.

Embodiment 2

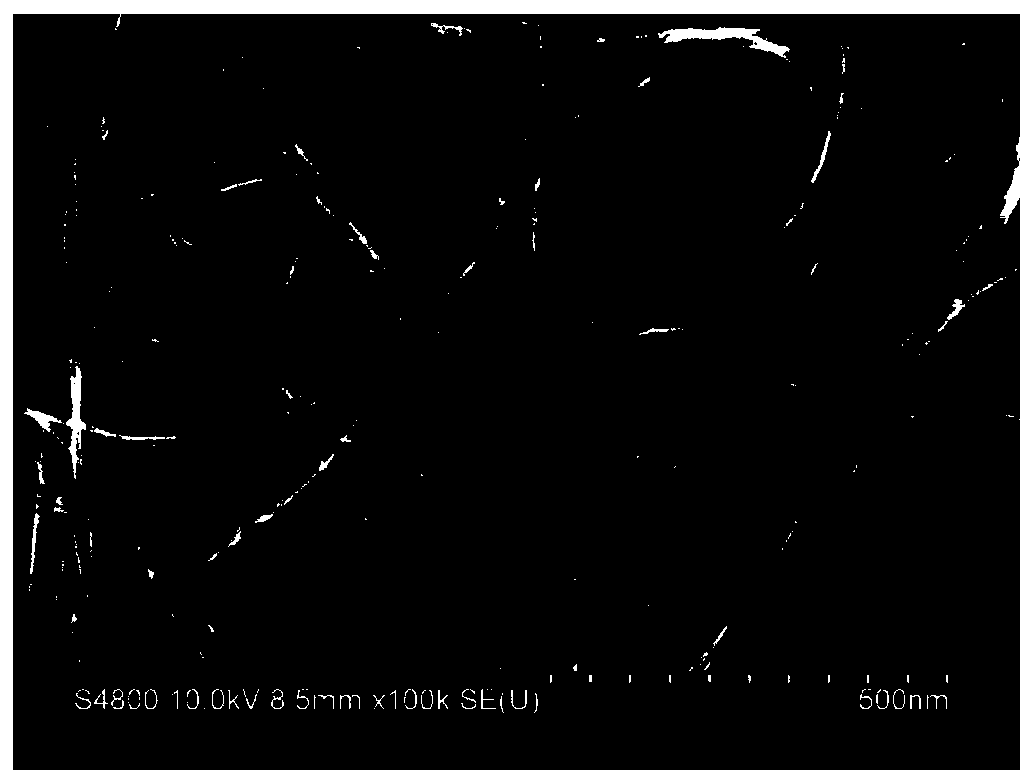

[0051] Weigh 0.4g of benzenesulfonic acid and dissolve it in 40mL of 1,3-dimethyl-2-imidazolidinone, add 40mg of single-walled carbon nanotubes after complete dissolution, stir at room temperature at a speed of 300r / min while ultrasonicating for 30min, A dispersion of single-walled carbon nanotubes was obtained. Then, take 8 mg of intrinsic state polyaniline (same as Example 1) and dissolve it in 20 mL of 1,3-dimethyl-2-imidazolidinone. After completely dissolving, add dropwise at a uniform speed to the dispersion of single-walled carbon nanotubes. solution, and continued ultrasonication and stirring for 30 min, so that the single-walled carbon nanotubes were uniformly dispersed again after adding polyaniline. After the ultrasound is completed, the carbon nanotube / polyaniline composite material with a mass ratio of single-walled carbon nanotubes and polyaniline of 5:1 can be obtained by suction filtration and washing, which is denoted as (5SWCNT-BSA)@1PANI.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com