System for water plant capacity expansion and increment

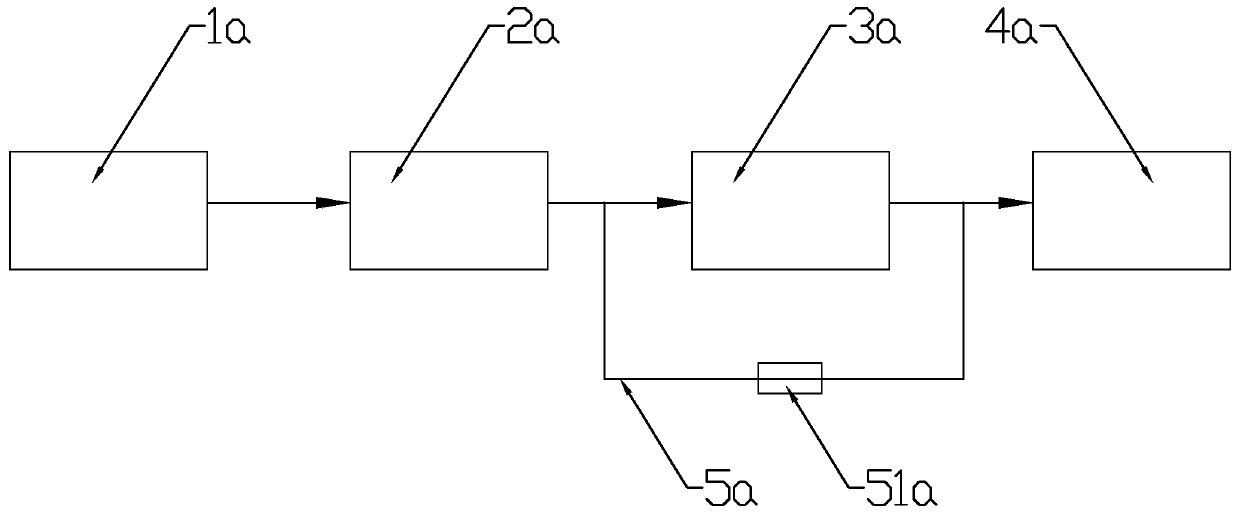

An incremental, water plant technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of large investment, failure to reach the long-term expected scale of urban water plants, and insufficient capacity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Water plant capacity expansion incremental system with different structures

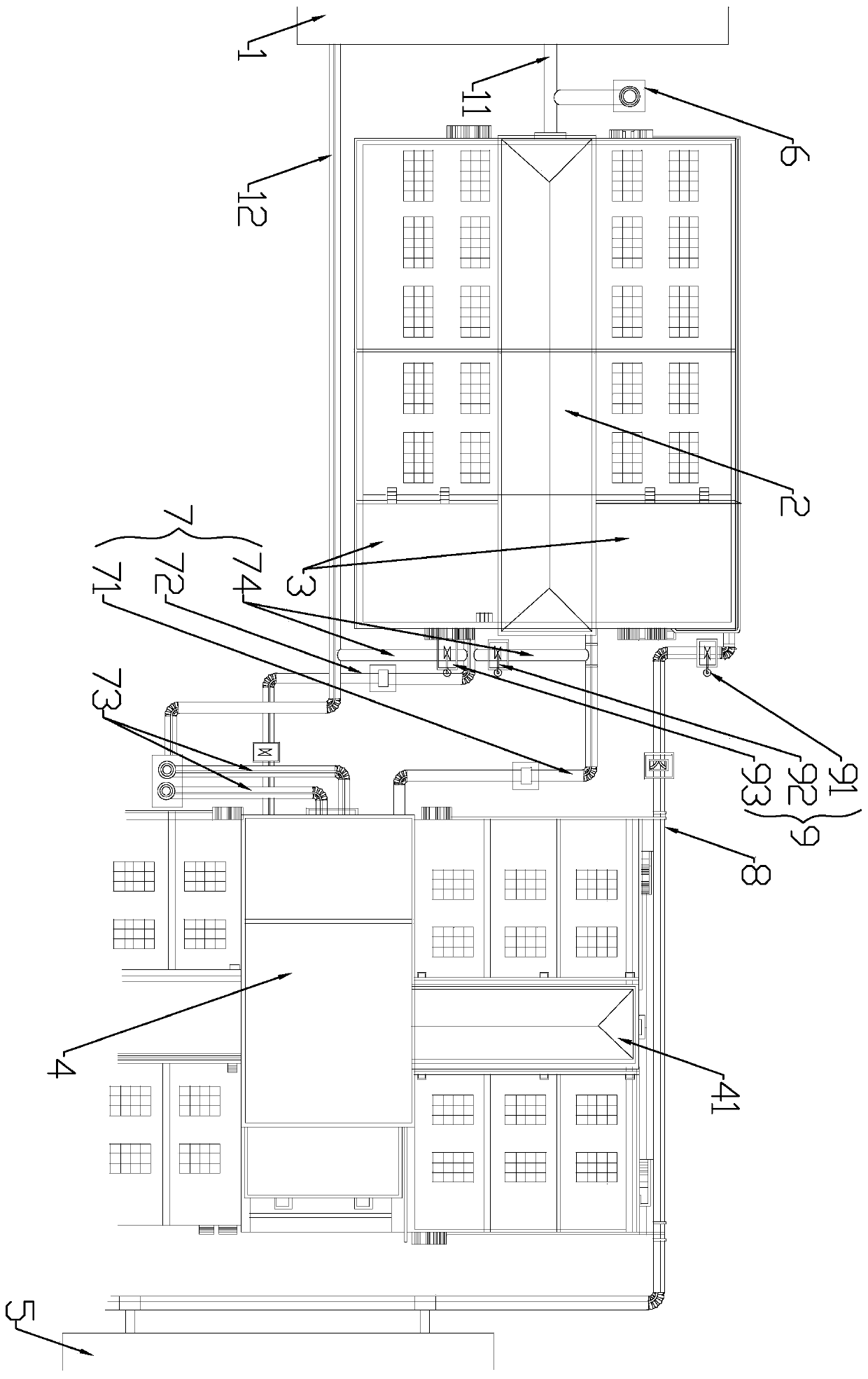

[0019] This embodiment is a system for water plant capacity expansion and increment, combined with figure 2 , including a sedimentation tank 1, a filter tank, a muddy water treatment tank, a dosing facility 6 and a clear water tank 5, wherein: the filter tank has a secondary filter tank, followed by an activated carbon filter tank 2 and an average filter material filter tank 4, and a sedimentation tank 1 Connect two water delivery branch pipes, the water delivery branch pipe one 11 is connected with the dosing facility 6, and the water to be treated and the medicament are sent to the activated carbon filter tank 2, and the water delivery branch pipe two 12 is sent to the uniform particle filter material filter tank 4; A muddy water treatment tank is set at the end of the pool 2, and the muddy water treatment tank is connected to the outlet pipe 8 and two distribution pipes 7, the o...

Embodiment 2

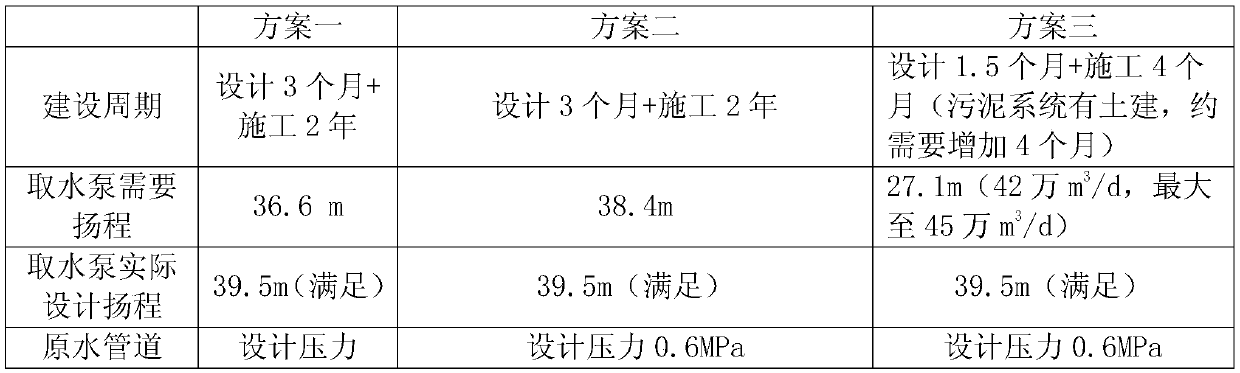

[0026] Example 2: Implementation of different expansion scales

[0027] Option 1: Expansion of 200,000 m 3 / d

[0028] 1. Expansion content:

[0029] 1) 200,000 m 3 One pre-ozone contact pool for / d;

[0030] 2) 100,000 m 3 / d Two flocculation and sedimentation tanks;

[0031] 3) 200,000 m 3 / d's uniform particle filter material filter 4 (in this case, the filter material uses carbon sand) one (including the backwashing machine room);

[0032] 4) The clean water pool 5 can no longer be built (the total storage volume is considered as 15%, which is about 3000m short 3 );

[0033] 5) Additional pumps Q=8125m in the second pump room 3 / h, H=51m, N=1250KW 2 sets of water pumps (1 for power frequency and 1 for frequency conversion, 4 for 1 for standby), including supporting equipment;

[0034] 6) Supporting sludge system (one thickening tank, one additional dehydrator and supporting equipment);

[0035] 7) Dosing facility 6 additional equipment (200,000 m 3 / d scale); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com