Control method of cracks of special steel cast blank

A control method and special steel technology, applied in flow control, non-electric variable control, control/regulation system, etc., can solve problems such as easy cracks on the surface of casting slabs, and achieve the effect that cracks are not easy to appear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

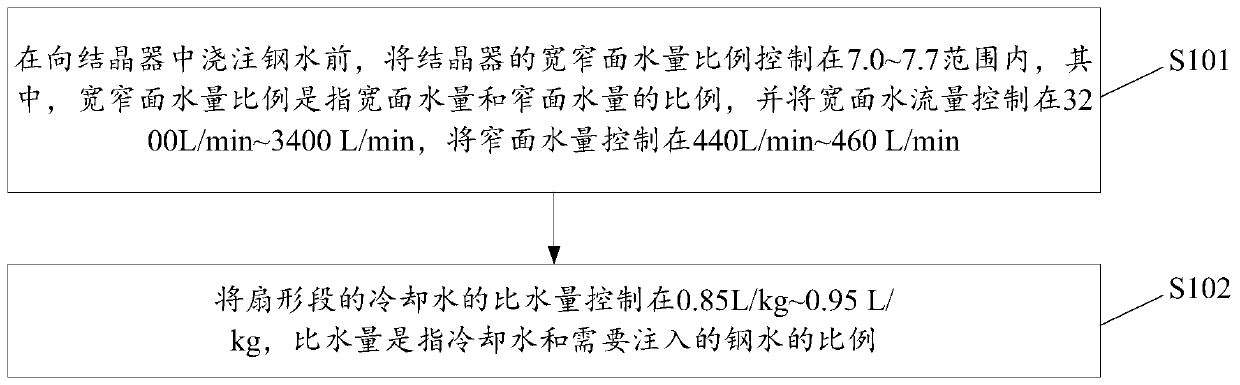

[0059] Such as figure 1 As shown, the present embodiment provides a method for controlling cracks in a special steel slab, including:

[0060] Step S101: Before pouring molten steel into the mold, control the ratio of water volume on the wide and narrow sides of the mold within the range of 7.0 to 7.7, wherein the ratio of water volume on the wide and narrow sides refers to the ratio of the water volume on the wide side to the water volume on the narrow side, and the ratio of the water volume on the wide side to the narrow side The water flow is controlled at 3200L / min to 3400L / min, and the water flow at the narrow surface is controlled at 440L / min to 460L / min.

[0061] In the specific implementation process, step S101 is an improvement on the control technology of the first cooling of the continuous casting machine (that is, the cooling water in the crystallizer).

[0062] In the specific implementation process, the special steel refers to peritectic steel containing Cu (cop...

Embodiment 2

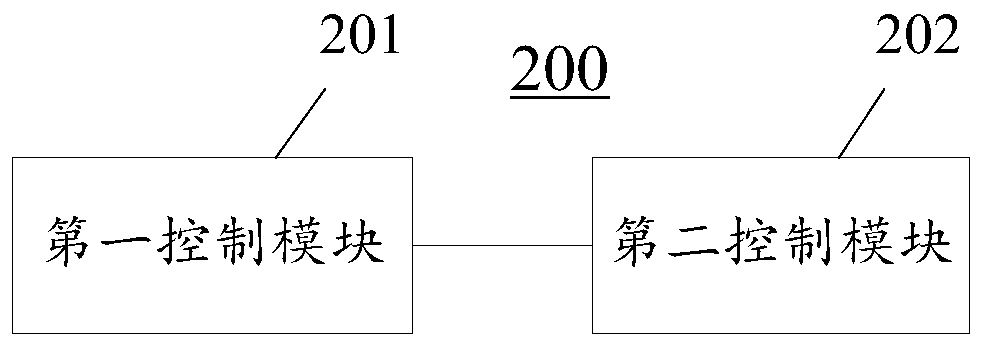

[0092] Based on the same inventive concept, this embodiment provides a control device for cracks in a special steel slab, which is used to automatically realize the control method for cracks in a special steel slab in the first embodiment above by adopting automatic control technology, thereby improving the control accuracy. Improve control efficiency and reduce the workload of workers on site.

[0093] Such as figure 2 As shown, the special steel slab crack control device 200 provided in this embodiment includes:

[0094] The first control module 201 is used to control the water volume ratio of the wide and narrow surfaces of the mold within the range of 7.0 to 7.7 before pouring molten steel into the mold, wherein the water volume ratio of the wide and narrow surfaces refers to the water volume of the wide surface and the water volume of the narrow surface. The ratio of the water volume of the surface, and the water flow rate of the wide surface is controlled at 3200L / min~...

Embodiment 3

[0106] Based on the same inventive concept, this embodiment provides an industrial control computer, which is used to automatically implement the control method for the cracks of the special steel slab in the above-mentioned embodiment 1 by adopting the automatic control technology, thereby improving the control accuracy, improving the control efficiency, and Reduce the workload of workers on site.

[0107] Such as image 3 As shown, the industrial control computer 300 provided in this embodiment includes: a memory 310, a processor 320, and a computer program 311 stored on the memory 310 and operable on the processor 320. When the processor 320 executes the computer program 311, the following step:

[0108] Before pouring molten steel into the crystallizer, the water volume ratio of the wide and narrow surfaces of the mold is controlled within the range of 7.0 to 7.7, wherein the water volume ratio of the wide and narrow surfaces refers to the ratio of the water volume of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com