Environmentally-friendly coating material equipment

A technology of environmentally friendly coatings and equipment, applied in the directions of dissolution, mixer, chemical instruments and methods, etc., can solve problems such as the impact of anti-corrosion performance of coatings, and achieve the effect of expanding the bearing area of support and achieving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

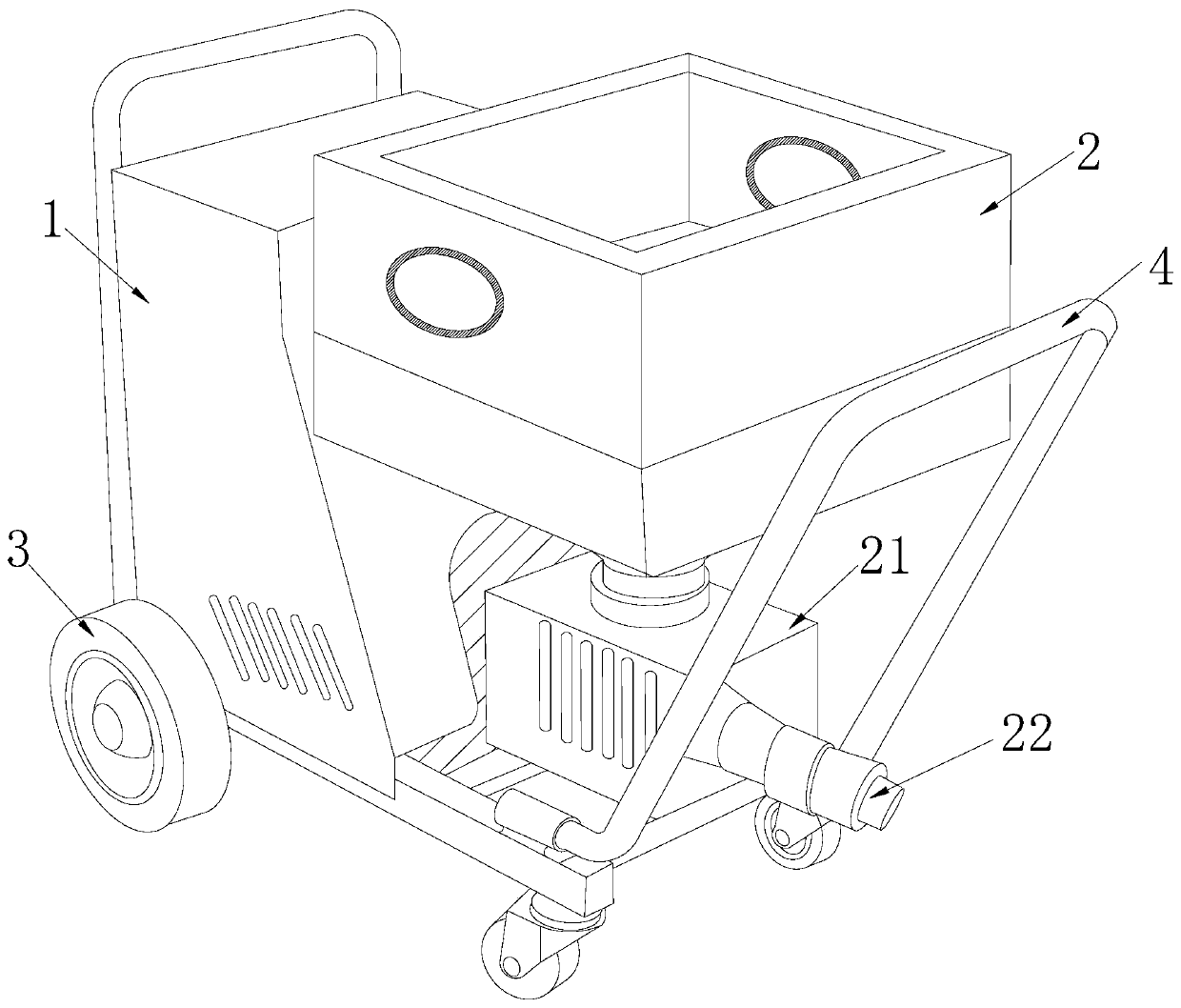

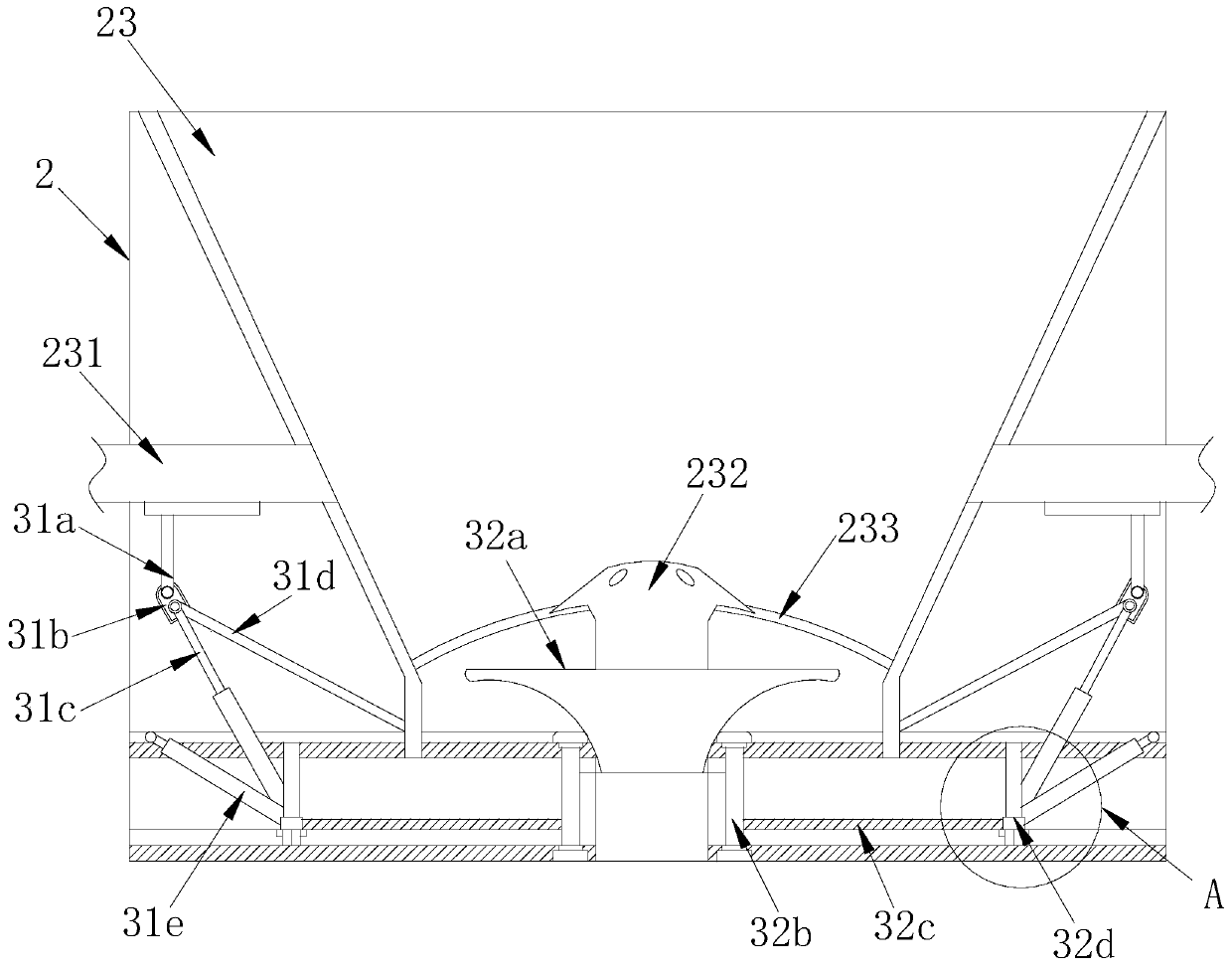

[0025] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of environment-friendly coating equipment, and its structure comprises control cabinet 1, dispersion box 2, moving wheel 3, handle 4, is formed with press 21, discharge port 22 and dispersion chamber 23 in described dispersion box 2 , the moving wheel 3 is provided with four, wherein the moving wheel 3 near the discharge port 22 has a brake pad, and the handle 4, the control cabinet 1, and the press machine 21 are all installed on the frame. The press 21 is provided with a discharge port 22, the bottom of the dispersion box 2 is set together with the press 21, and the dispersion chamber 23 is funnel-shaped.

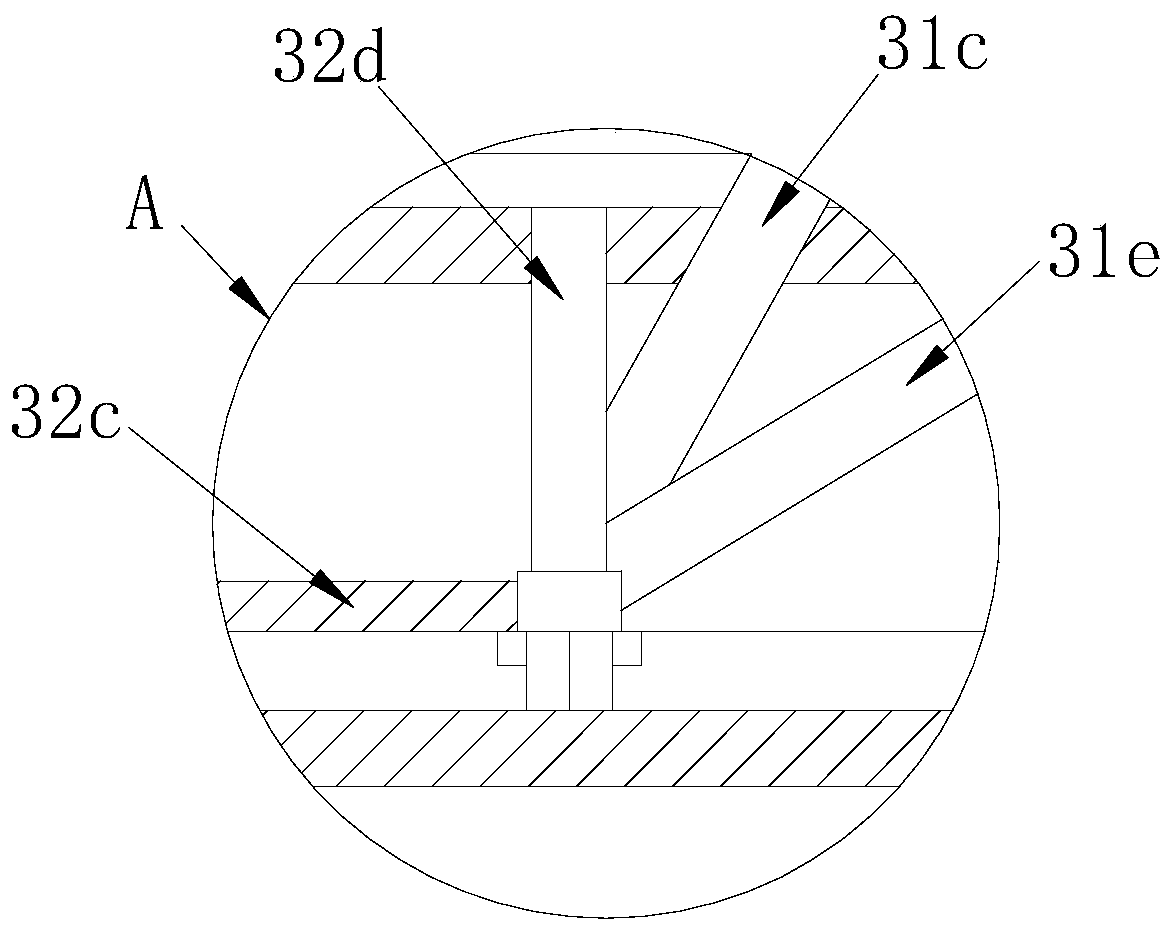

[0026] The inner bottom end of the dispersion chamber 23 is equipped with an agitator 232 and a carrying plate 233, the agitator 232 is fixed on the central raised position of the carrying plate 233, and the carrying plate 233 is made of an elastic material into an arc-shaped structure. Bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com