Self-stirring type adjustable filler pouring device and work method thereof

An adjustable and self-stirring technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of slow material cutting and the inability to pour fillers evenly at the long slit-shaped outlet, so as to improve pouring efficiency and ensure uniformity , the effect of uniform filler distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

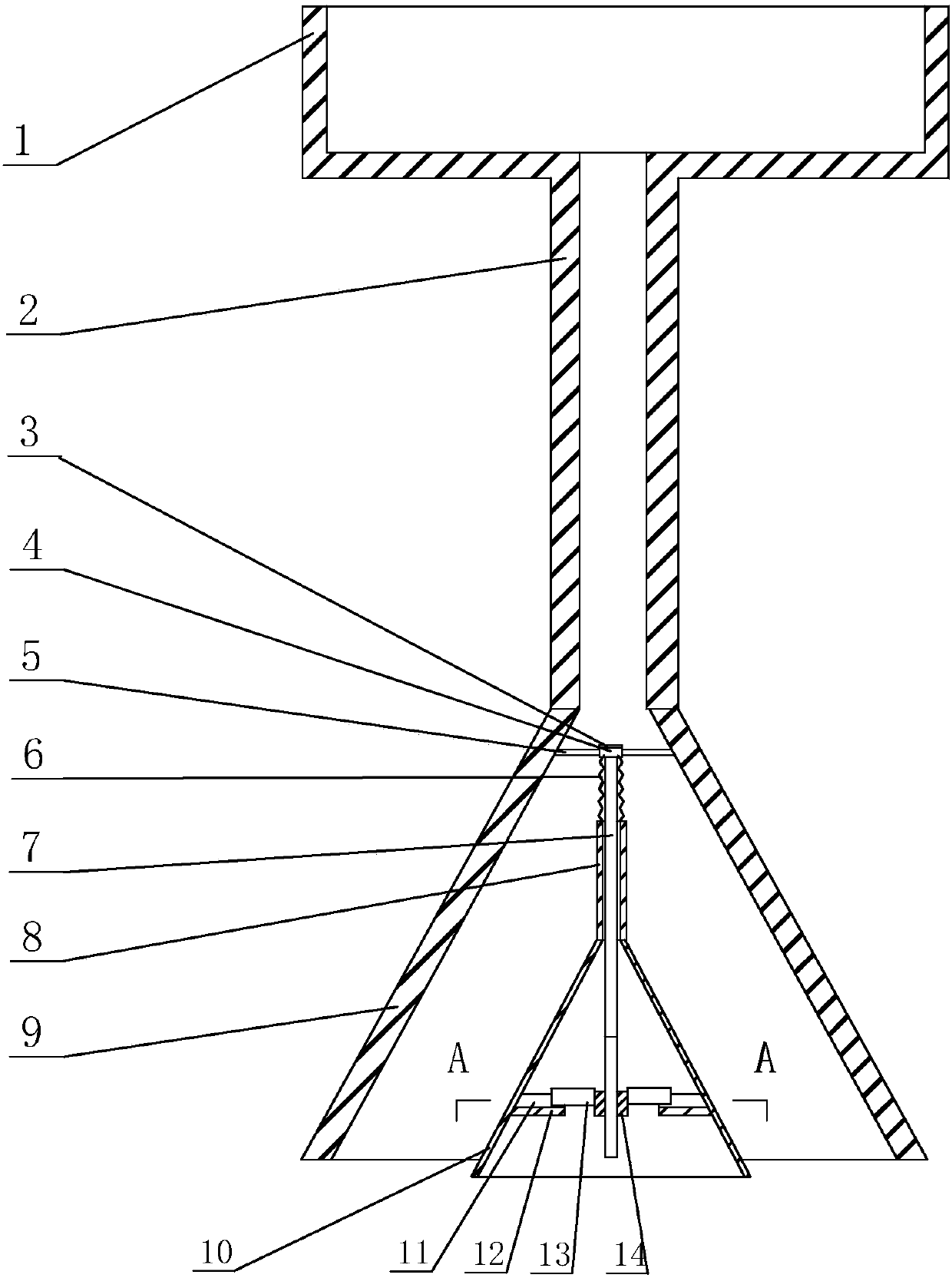

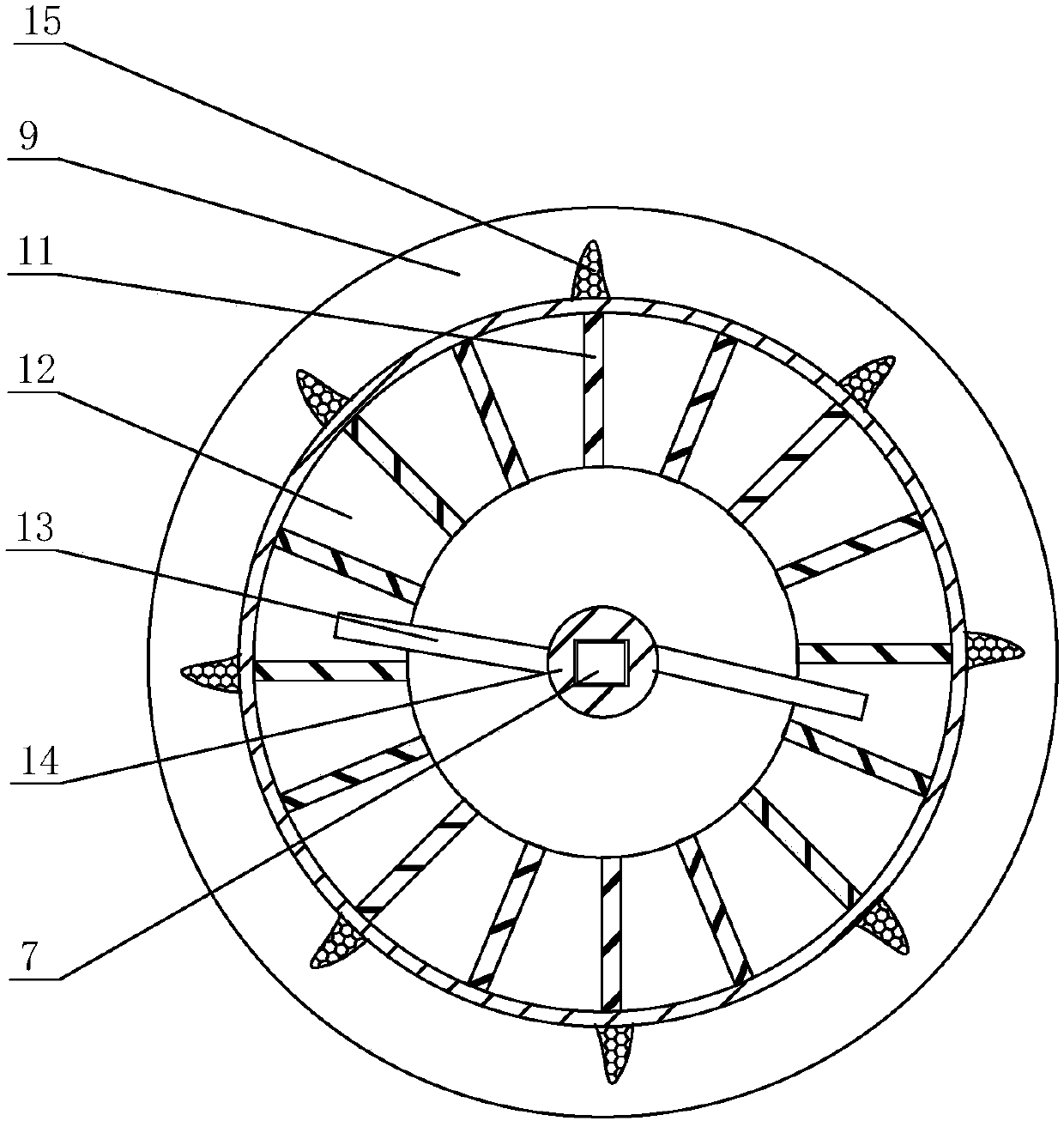

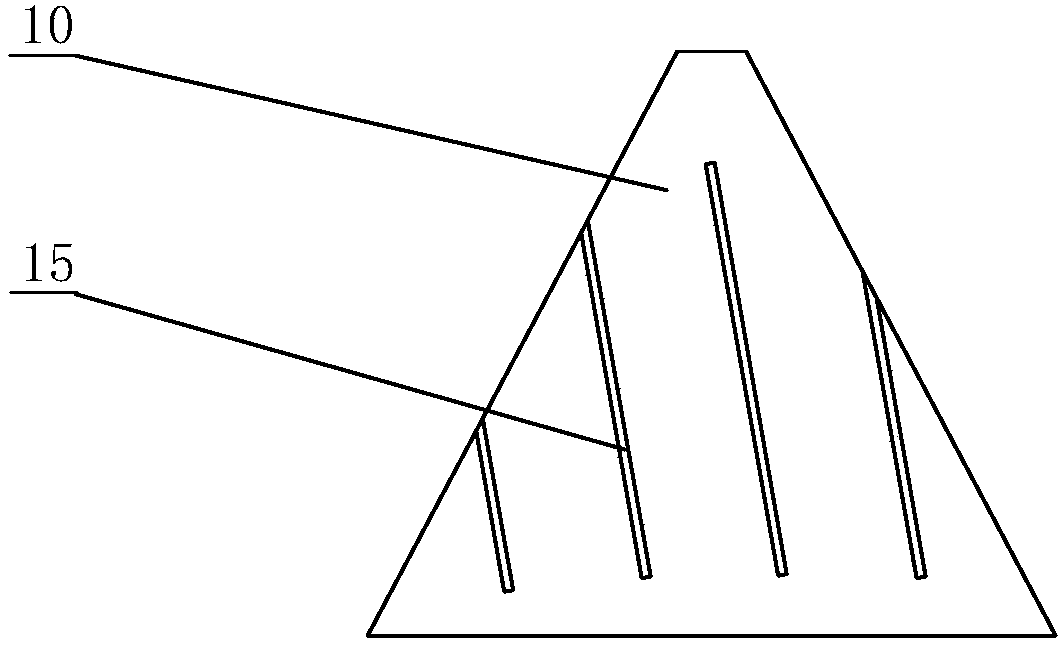

[0015] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0016] Such as Figure 1-Figure 3 As shown, the self-stirring adjustable pouring filling device of the present invention includes a hopper 1, the lower part of the hopper 1 is connected to the sand pouring pipe 2, and the lower end of the sand pouring pipe 2 is connected to the sand pouring bucket 9, and the sand pouring bucket 9 is narrow at the top and wide at the bottom. In the shape of a conical cylinder, a bearing 4 is arranged in the sand pouring bucket 9, and the bearing 4 is fixed on the inner wall of the sand pouring bucket 9 through a fixed piece 5. The fixed piece 5 is vertically fixed on the outer ring of the bearing 4, and the threaded rod is fixed on the inner ring of the bearing 4. 7. The threaded rod 7 is fitted with a threaded cylinder 8. The lower part of the threaded rod 7 is in the shape of a smooth quadrangular prism. The lower end of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com