A kind of copper clad laminate lamination method

A copper-clad laminate and lamination technology, which is applied in the field of copper-clad laminate, can solve the problems of uneven distribution of fillers in copper-clad laminates, and achieve the effects of reducing voids and bad interfaces, increasing the amount of addition, and stacking tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Take CEM-3 core bonding sheet as an example, the filler mass fraction is 85%, and the filler is alumina. The rheometer tests its T at a heating rate of 1.2°C / min 1 90°C, T 2 is 125°C. First, some high-frequency vibrators 2 are arranged on the upper and lower cover plates 1 used for lamination (see figure 1 ), and then assemble the laminated materials, mirror panels, upper and lower cover plates, and put them into a hot press for lamination.

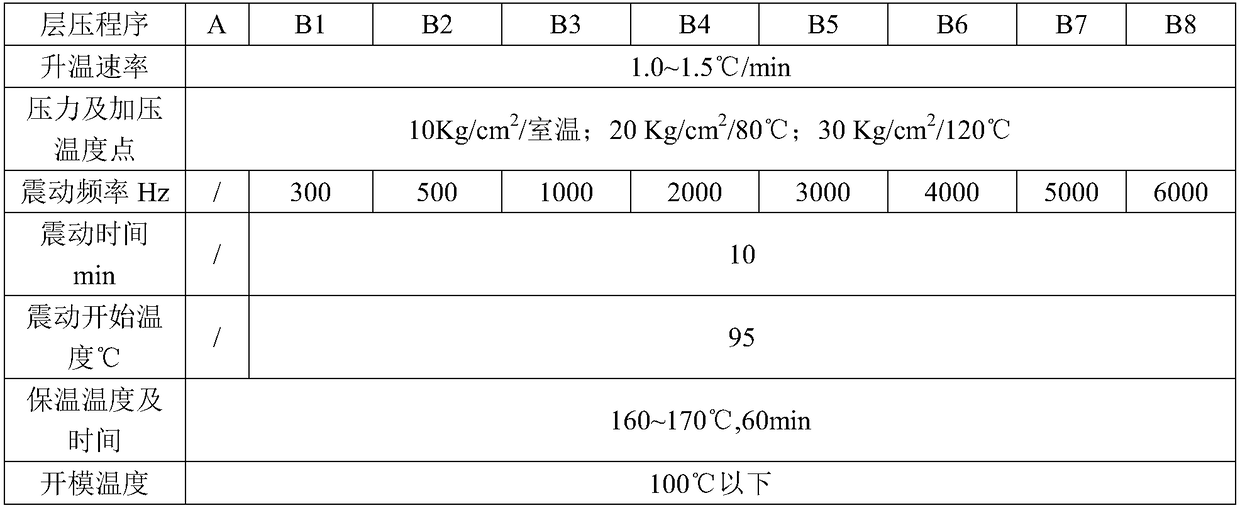

[0020] A in Table 1 is the traditional lamination procedure A, as a comparative example; B1-B8 are lamination procedures with different vibration frequencies applied.

[0021] Table 1

[0022]

[0023] Performance test results:

[0024]

[0025] It can be seen that the appearance, water absorption and thermal conductivity of the plate subjected to vibration lamination are all improved,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com