Full-automatic removing machine for concrete sundries

A fully automatic, concrete technology, applied in the field of machinery, can solve the problems of difficult to remove debris, low work efficiency, affecting product quality stability, etc., to achieve the effect of ingenious structural design, high work efficiency, and strong debris capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

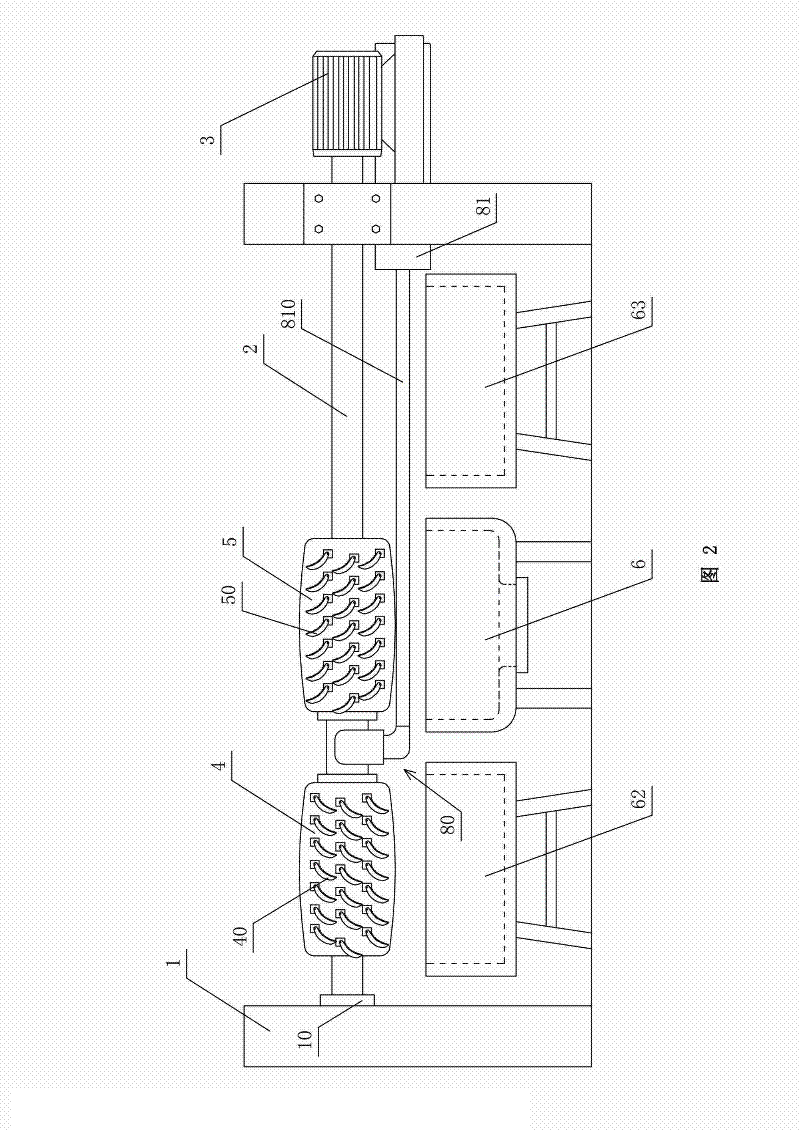

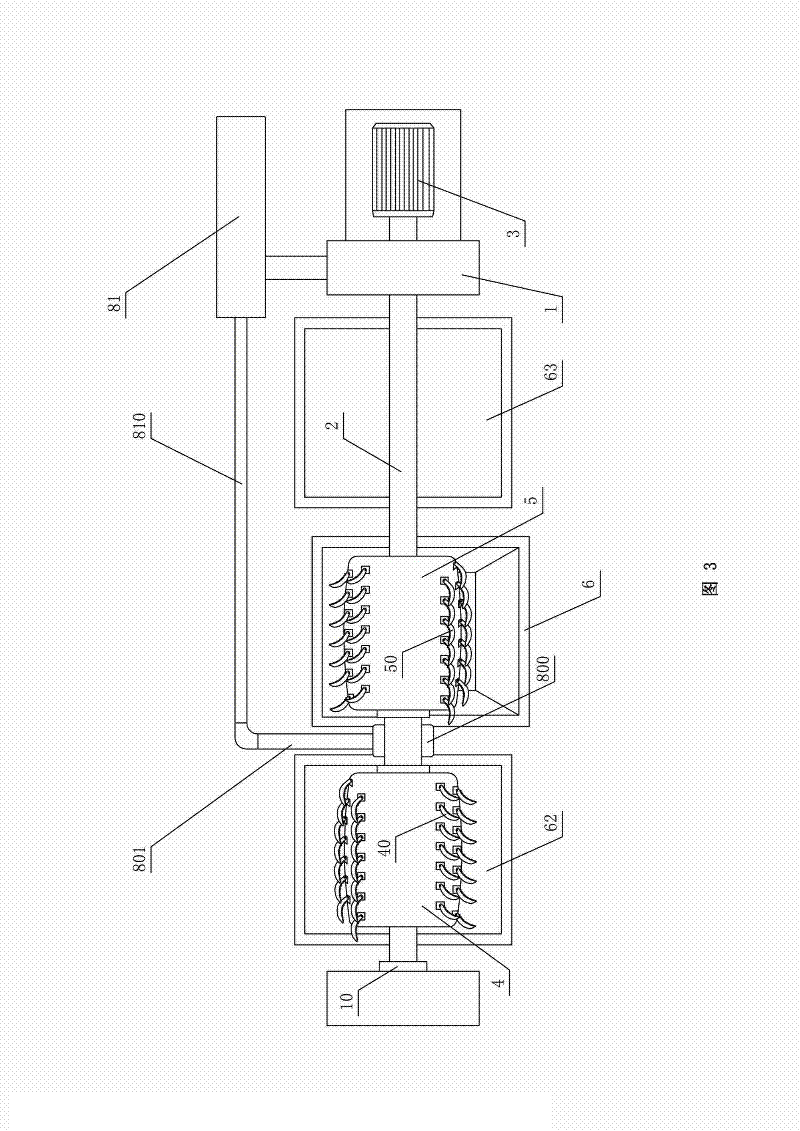

[0025] refer to figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 and Figure 7 . Concrete debris automatic clearing machine, including a bracket 1, a rotating shaft 2 rotatably arranged on the bracket 1, a rotating motor 3 driving the rotating shaft 2 to rotate, left and right rollers slidably sleeved on the rotating shaft 2 4,5, the material chute 6 that cooperates alternately with the left and right rollers 4,5 and the feeding and discharging conveyor belts 60,61, the material chute 6 is located below the rotating shaft 2, and also includes the left and right rollers 4,5 respectively Cooperating two sundries buckets 62,63 and the horizontal driving mechanism that drives left and right cylinders 4,5 to move horizontally on the rotating shaft 2, these two sundries buckets 62,63 are respectively located at the left and right sides of the hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com