Composite coating pot, surface treatment method of pot, and electromagnetic heating appliance

A technology for composite coating and cookware, applied in the fields of electromagnetic heating utensils and composite coating cookware, can solve the problems of inability to achieve rapid heating, high thermal inertia, low energy efficiency value, etc., and achieve excellent adhesion and improved scratch resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

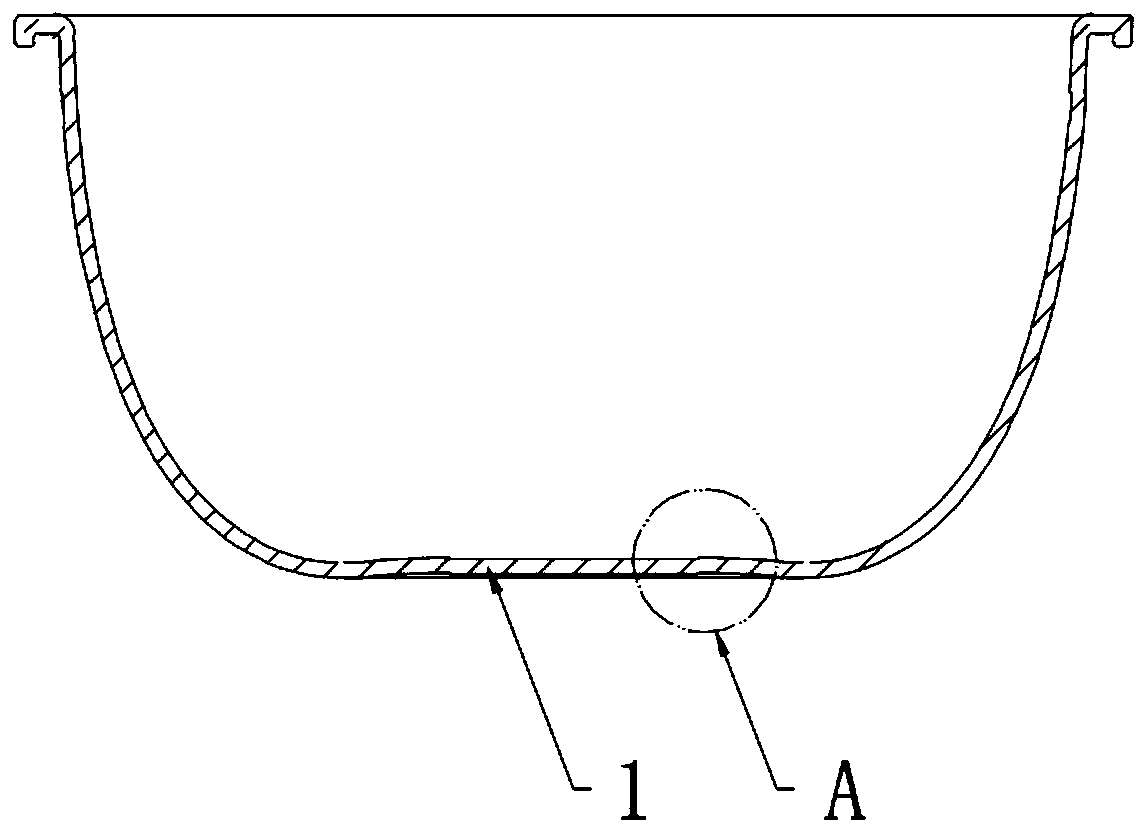

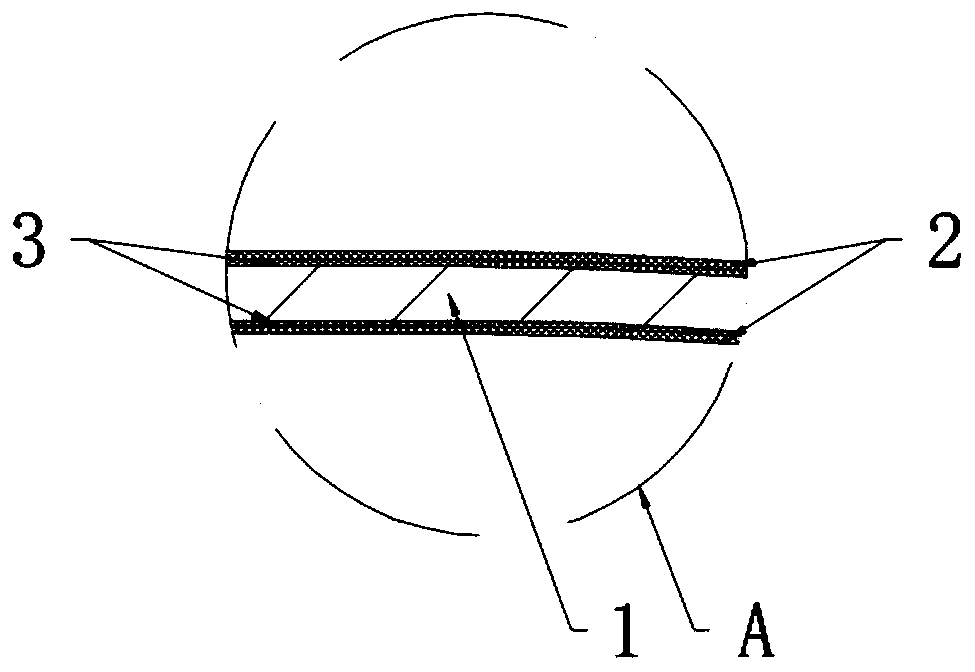

[0034] A composite coating cookware, the cookware 1 includes a bottom wall and a side wall connected to the bottom wall, the cookware 1 also includes a composite coating formed on the surface of the cookware 1, the composite coating There are at least two layers, including at least one base layer 3 and at least one surface layer 2 sprayed in sequence. Wherein, the cookware 1 is a cookware made of carbon-based composite material or carbon fiber material, and the carbon-based composite material of the cookware 1 is a carbon / carbon composite material containing glassy carbon material.

[0035] How it works: as Figure 1-2 As shown, in this technical solution, the cookware 1 is a cookware made of carbon-based composite materials or carbon fiber materials, wherein the carbon-based composite materials have low density (<2.0g / cm3), high specific modulus, high Magnetic conductivity, high thermal conductivity, low expansion coefficient, good thermal shock resistance, and high dimensio...

Embodiment 2

[0042] A surface treatment method for a composite coating pot, comprising the following steps:

[0043] Step 1: Plasma treatment is performed on the inner and outer surfaces of the cookware for 3 to 15 minutes;

[0044] Step 2: spray at least one base layer on the inner and outer surfaces of the cookware after plasma treatment, the spraying distance is 10~60mm, more preferably 50~60mm, the spraying angle is 40~80 degrees, and more preferably 45~60mm 55 degrees, the base layer is a resin film coating with good compatibility with carbon-based composite materials, the thickness of the base layer is about 10-40 μm, and it is naturally dried for 2-4 hours;

[0045] Step 3: After the base layer is dried, a transition layer is sprayed on the inner and outer surfaces of the cookware. The transition layer is a primer mixed with 10% to 50% of uncured resin. The components of the uncured resin in the transition layer The composition of the base layer is the same, and it is naturally dri...

Embodiment 3

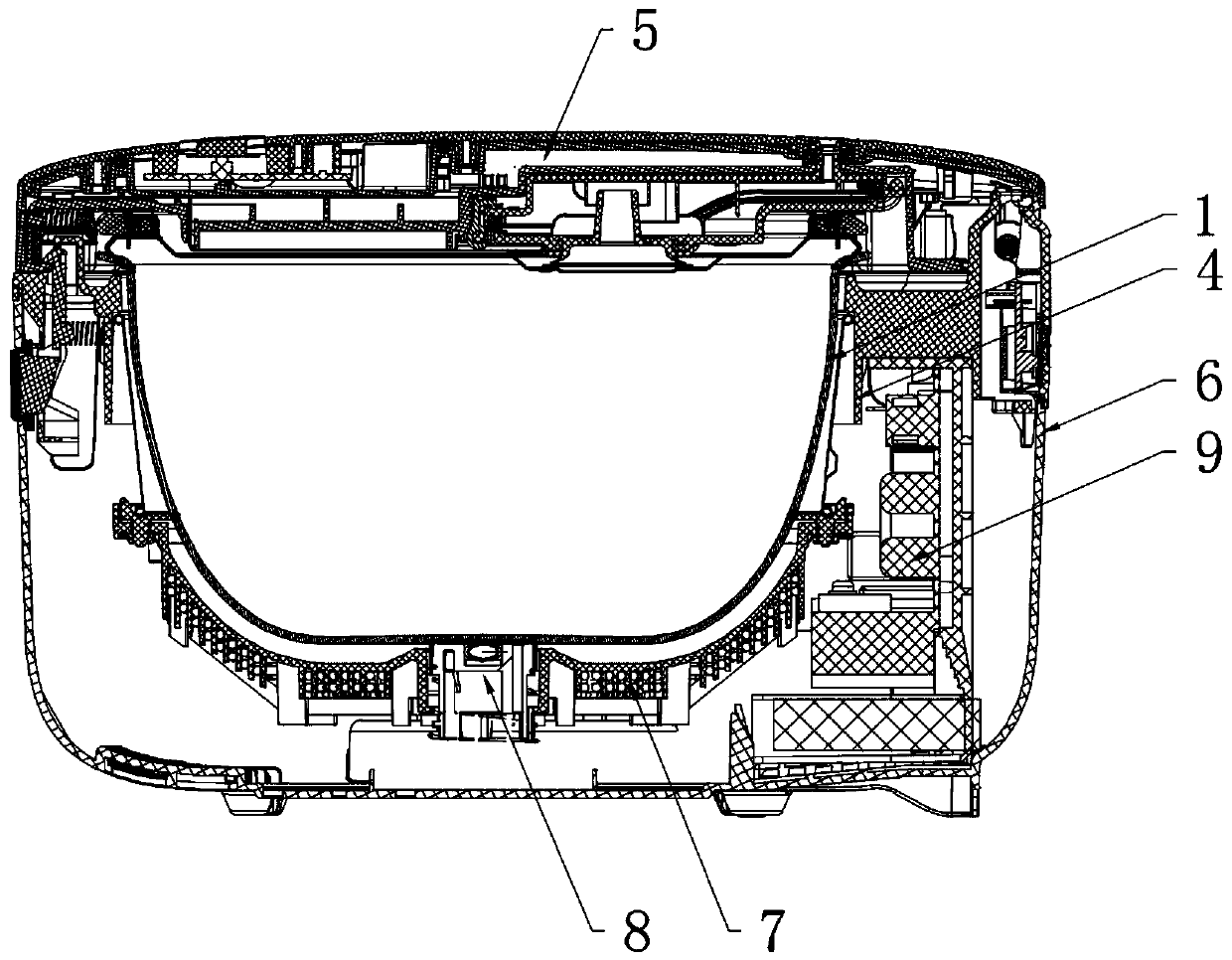

[0049] An electromagnetic heating appliance includes an appliance body 4, an upper cover 5 connected to the appliance body 4 and fastened to the open end of the appliance body 4, and the interior of the appliance body 4 is equipped with the above-mentioned composite coating cookware. The appliance body 4 has the characteristics of high power, fast heating speed and high energy efficiency, and has good cooking effect.

[0050] Further, in this embodiment, it can be considered that the appliance body 4 includes an outer pot 6 and an assembly area between the appliance body 4 and the outer pot 6, and the bottom or bottom and side walls of the outer pot 6 are provided for The coil disc 7 that generates electromagnetic, the bottom of the outer pot 6 is provided with a thermostat 8, the inner surface of the assembly area is provided with a circuit board 9, the thermostat 8 and the coil disc 7 are integrated into the circuit through wires on board 9.

[0051] Furthermore, in this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com